Continuous treatment device and method suitable for high-flow meta-position aramid spinning bath lotion

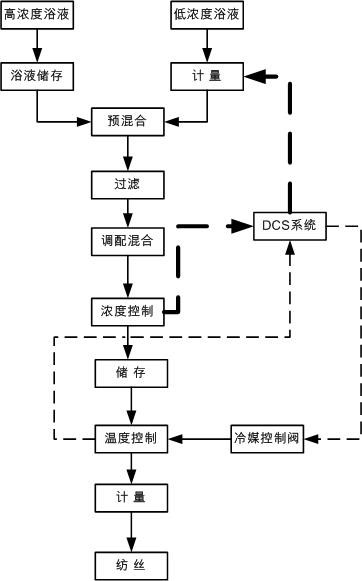

The technology of a processing device and a processing method, which is applied in the field of chemical engineering, can solve the problems of lag in concentration control, instability, and the inability of the spinning bath to be cleaned, and achieve the effects of improving recovery efficiency, improving product quality, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

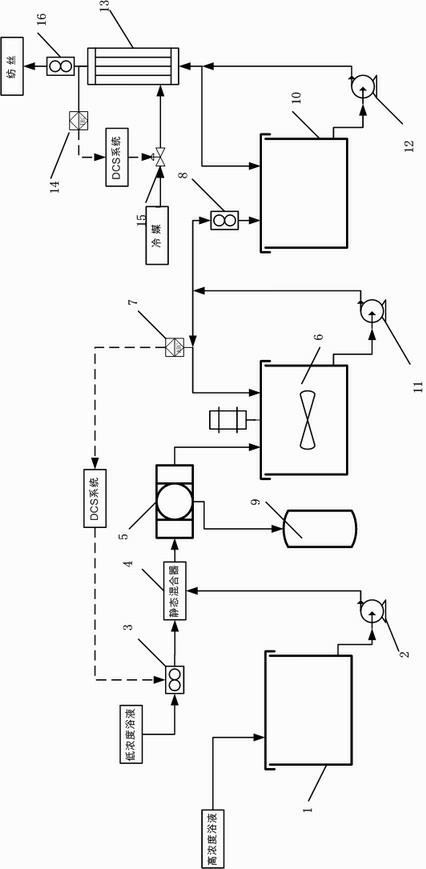

Method used

Image

Examples

Embodiment example

[0042] Further illustrate the substantive characteristics and remarkable progress of the invention through the following implementation examples, and the parts and percentages involved in the following examples are all parts by weight unless otherwise specified.

example 1

[0044] The flow rate is 50m 3 The concentration of meta-aramid fibers with a concentration of 45.8% produces turbid spinning bath liquid through the pipeline into the spinning bath receiving tank. The impurity content is 3.50% after testing. The quantitative translucent spinning bath liquid (impurity content is 0.94%) is pre-mixed and filtered into a centrifugal filter with a filtration accuracy of 50um. The filter screen is a dense mesh woven with metal wires, and the diameter of the warp and weft wires is 0.14mm× 0.10mm, the filtered clear liquid is sampled and tested to have an impurity content of 0.012%. It enters the spinning bath blending tank for further mixing and blending concentration. The impurity outlet of the filter is connected to the filter residue storage tank; Part of the pump circulates into the blending tank for remixing, the concentration is set at 42%, and the concentration measured by the concentration meter connected to the circulation pipeline is 42.1%;...

example 2

[0046] The flow rate is 42m 3The concentration of 53.2% of the meta-aramid fiber production turbid spinning bath enters the spinning bath receiving tank through the pipeline, and the impurity content is 4.32% after testing. The quantitative translucent spinning bath liquid (impurity content is 1.35%) is pre-mixed and filtered into a centrifugal filter with a filtration accuracy of 50um. The filter screen is a dense mesh woven with metal wires, and the diameter of the warp and weft wires is 0.14mm× 0.10mm, the filtered clear liquid is sampled and tested to have an impurity content of 0.018%. It enters the spinning bath blending tank for further mixing and blending concentration. The impurity outlet of the filter is connected to the filter residue storage tank; Part of the pump circulates into the blending tank for remixing, the concentration is set at 42%, and the concentration measured by the concentration meter connected to the circulation pipeline is 42.0%; part of it is qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com