Patents

Literature

97 results about "Bath puva" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bath PUVA treatment Psoralen is administered topically to the skin as a diluted bath solution and the medicament penetrates your skin while you immerse in water. In comparison to oral treatment with Psoralen tablets, bath PUVA treatment is usually better tolerated and requires lower UVA doses.

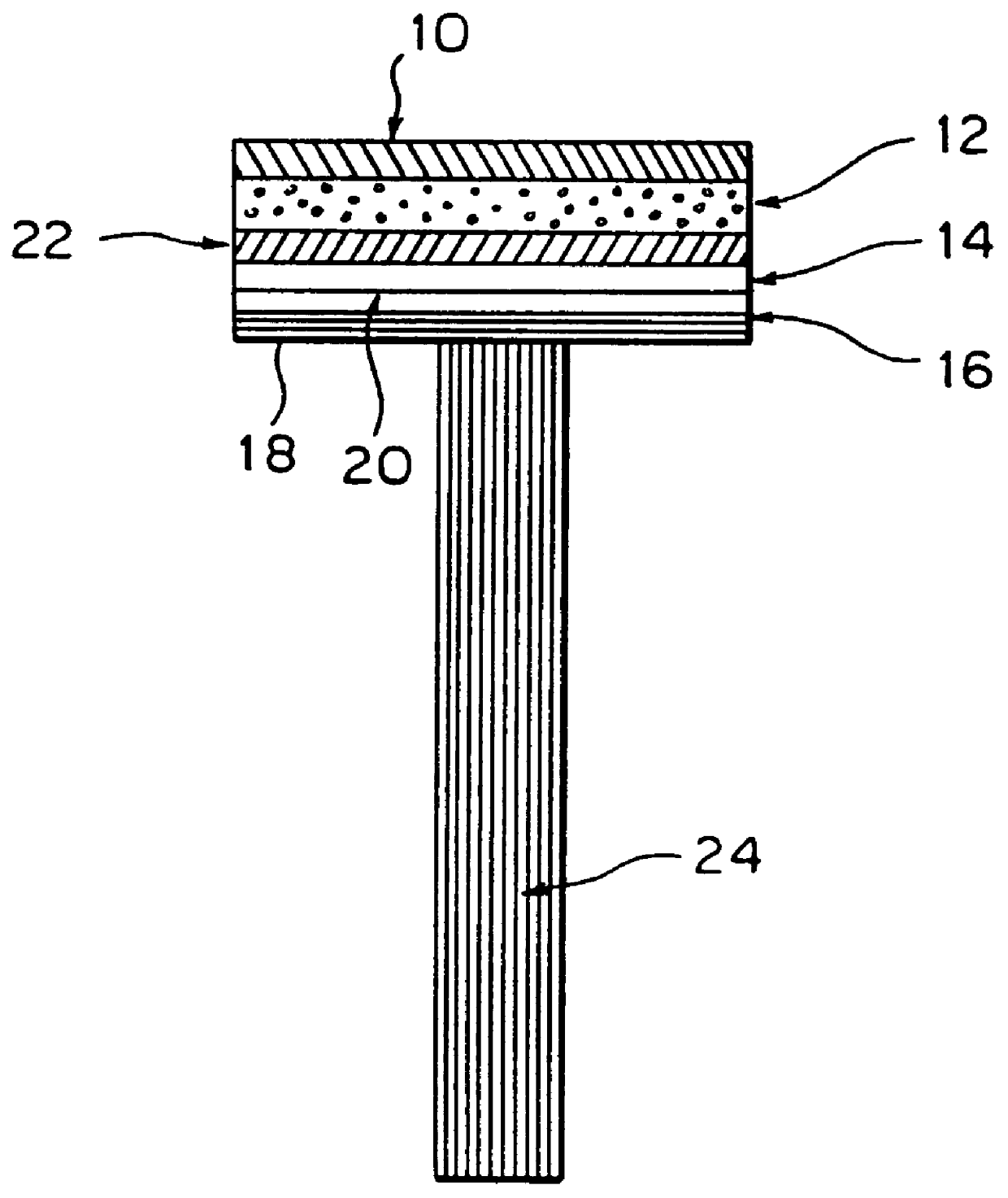

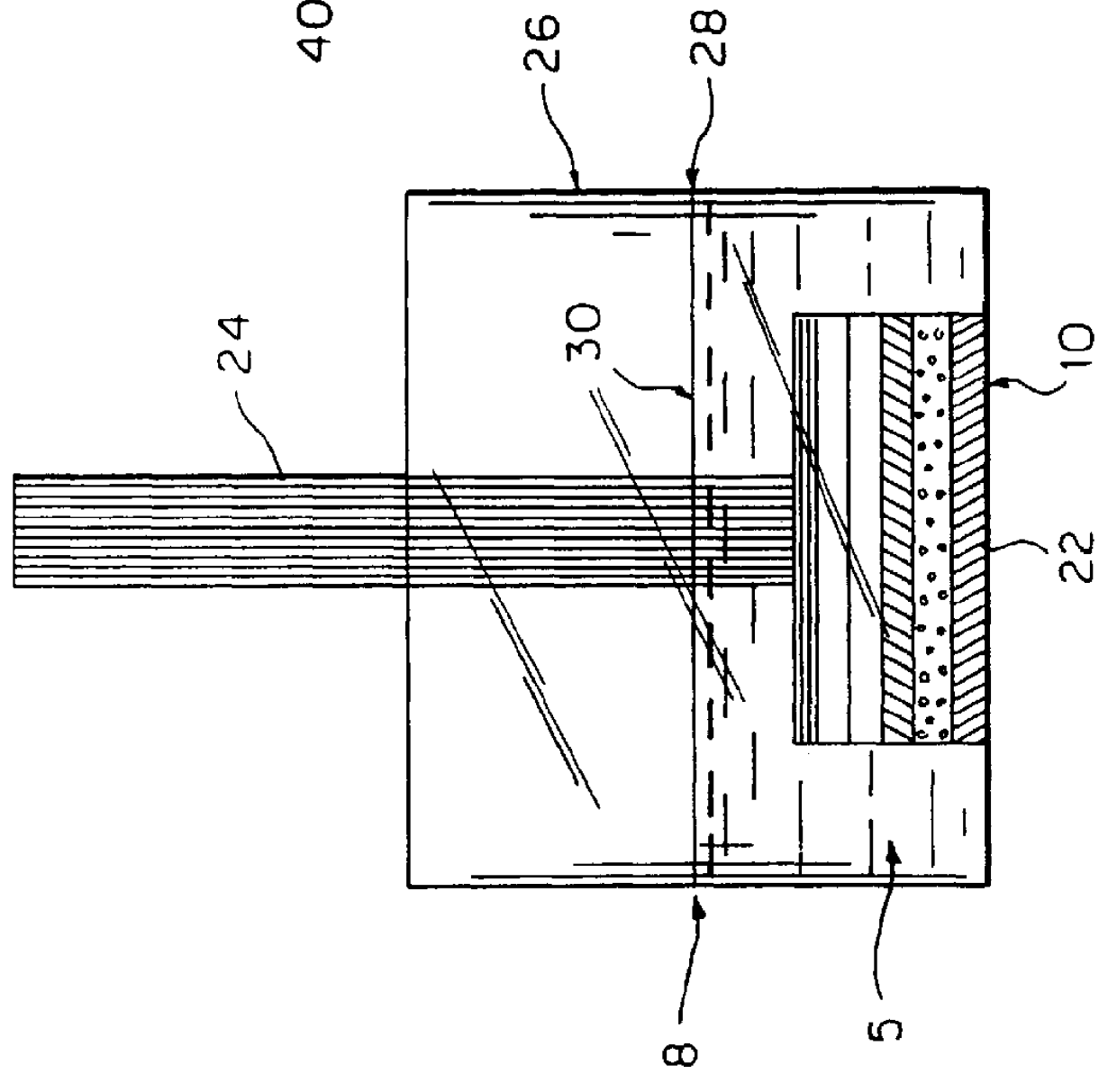

Disposable washcloth article and a method of making and using the washcloth

InactiveUS20030207632A1Increasing and causing rednessIncreasing and causing and irritationCosmetic preparationsToilet preparationsPreservativeAlpha hydroxy acid

This invention relates to a disposable washcloth and a method of making and using the washcloth. The disposable washcloth includes an aqueous solution incorporated onto a nonwoven basesheet. The aqueous solution includes a combination of a moisturizer, a humectant, an alpha hydroxy acid compound, a skin vitamin, a mild surfactant and a preservative. A method of making and using the disposable washcloth includes providing a continuous web of nonwoven basesheet material onto which the aqueous solution is incorporated. The continuous web is longitudinally folded and transversely cut to provide a plurality of individual washcloths. A select number of the individual washcloths are stacked in a clip and placed in a package. The package of washcloths is heated to a select temperature above 98° F. One or more of the individual disposable washcloths are removed from the package to provide a warm, quick drying, moisturizing bath to a human being.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Ultraviolet-resistant production process of socks

InactiveCN101982125ASimple production processStable and reliable UV resistanceFibre treatmentPanty-hoseSOCKSUltraviolet

The invention discloses an ultraviolet-resistant production process of socks, which comprises the following steps: 1) impregnating the socks: impregnating the socks in bath solution with ultraviolet absorbent concentration of 4-10g / l, wherein the bath ratio is 1:8-1:15, the temperature of the bath solution is 30 DEG C-60 DEG C, and the impregnation time is 30-45min; 2) dehydrating the socks: dehydrating the socks which are well impregnated until the water content is 60%-80%; 3) carrying out fluffing treatment on the socks; 4) stereotyping the socks; and 5) drying the socks: drying the socks at the temperature of 120 DEG C-160 DEG C for 1-3min. The ultraviolet-resistant production process of the socks is simple, and ultraviolet-resistant components are uniformly distributed on the socks and stably combined with the socks; furthermore, the process can be adjusted in time if abnormal indexes exist during the production process, and the stability and the reliability of the ultraviolet-resistant performance of the socks can be ensured.

Owner:HAINING NAIER SOCKS

Shaving method

A method of shaving includes the steps of providing a bath comprised of an astringent liquid such as witch hazel extract and alcohol, soaking a razor head in the bath after each shave, and shaving with the razor while the razor head is still wet with the astringent liquid from the bath.

Owner:BENZINGER ROBERT W

Tibetan medicine medicated bath for treating psoriasis and use method thereof

ActiveCN104547988ARash subsidesClear stateInorganic active ingredientsPharmaceutical delivery mechanismMirabilis jalapaAsparagus cochinchinensis

The invention provides Tibetan medicine medicated bath for treating psoriasis. The Tibetan medicine medicated bath is prepared by preparing ephedra saxatilis, shug-pa, artemisia sieversiana, german tamarisk, rhododendron anthopogonoide, mirabilis jalapa, sealwort, radix asparagi, caltrop, sphallerocarpus gracilis, semen cassia, ambrette, frankincense, sulphur, orpiment, saffron crocus, ginger and rheum officinale, partially fermenting and decocting the components. The Tibetan medicine medicated bath provided by the invention can quickly and directly act on the lesions, perfect the vitality of skin tissues, enhance the metabolism of skin, promote the blood circulation of a human body, adjust the endocrine, discharge toxins in vivo, kill dermatophyte, enhance the immune function and ensure an obvious treatment effect; and the treatment process is comfortable and convenient and is free of toxic or side effect.

Owner:天祝藏族自治县藏医院

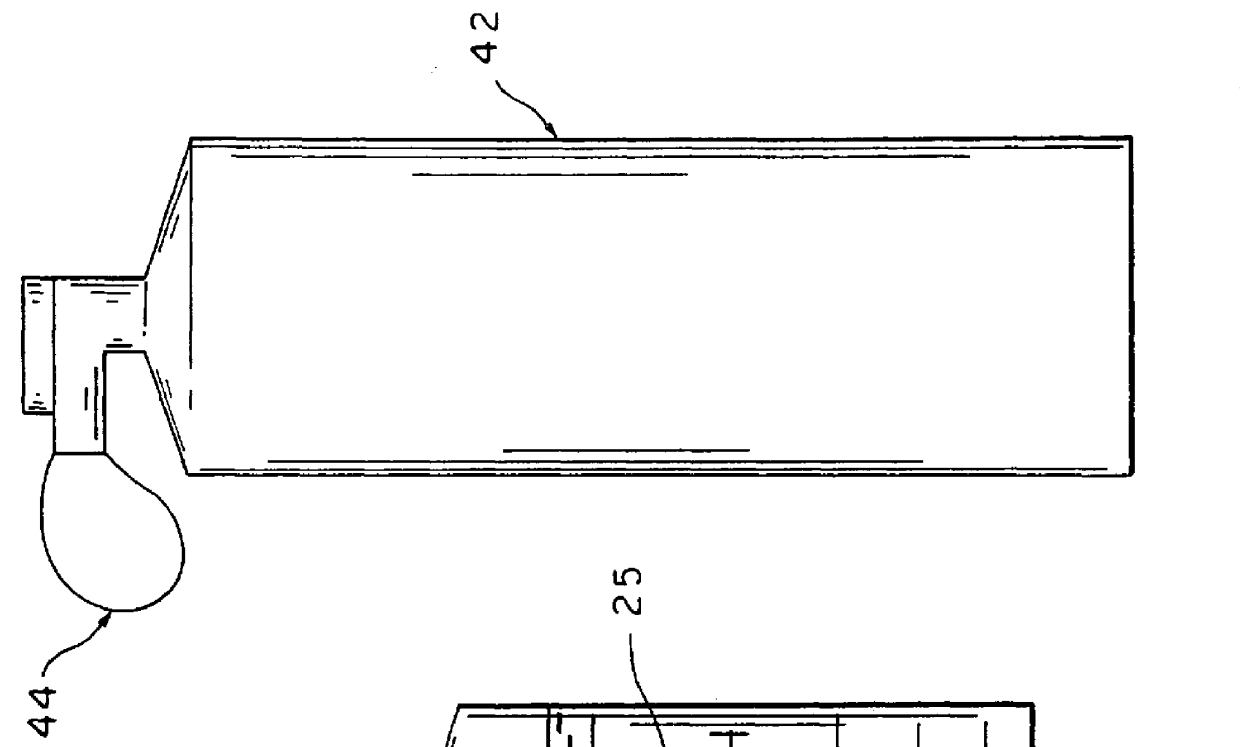

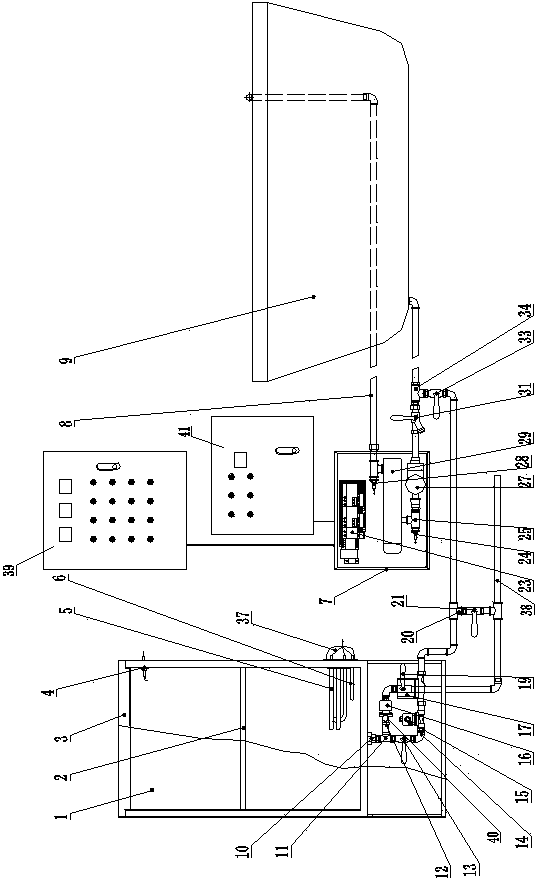

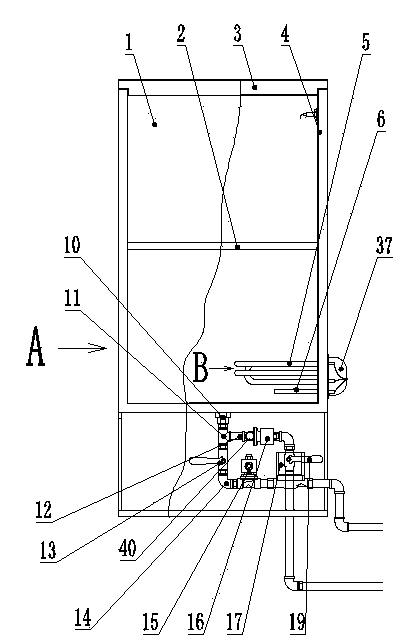

Full-automatic medicated bath device and control system thereof

ActiveCN103751005AImproves local tissue nutrition and systemic functionHarmonize qi and bloodBathing devicesSimultaneous control of multiple variablesTreatment effectEngineering

The invention relates to a full-automatic medicated bath device and a control system of the full-automatic medicated bath device. The full-automatic medicated bath device comprises a medicine decocting device, a medicated bath tub and a medicine liquid conveying device between the medicine decocting device and the medicated bath tub, and further comprises a medicine liquid circulating heating device. The control system of the full-automatic medicated bath device comprises a power supply module connected with an electric appliance control element, and the power supply module is connected with a medicine decocting heating control module, a medicated bath medicine liquid heating control module, a medicated bath medicine liquid conveying control module, a medicine liquid discharge level control module and a medicated bath medicine liquid level control module. In the medicated bath therapy process, medicine liquid can be heated in a circulating mode, the temperature of the medicated bath medicine liquid reaches needed constant temperature, heating is fast, time and labor are saved, fastness and energy saving are achieved, quality is reliable, safety and environmental protection are achieved, low carbon is achieved, pollution is avoided, the cost of medicated bath therapy is lowered, the therapy effect is remarkable, the device can stop work in the state of having no medicine and lacking medicine, the device does not need to be managed by special personnel in daily use, and the automation degree is high.

Owner:肃南裕固族自治县藏八宝药浴设备制造厂

An artificial hot spring bathing agent and its preparation

InactiveCN101006966AReduce secretionRelaxCosmetic preparationsToilet preparationsHot springCurative effect

The invention discloses a bathing agent for artificial hot springs and process for preparing same, wherein the formulation comprises sodium sulfate powder 45-55%, sodium chloride 35-45%, soda 5-20%, potassium chloride 1-5%, sodium borate 1-5%, magnesium sulfate 1-5%, potassium iodide 0-0.3%. The invention also discloses the process for preparing the bathing agent for artificial hot springs, which can be used for the subsidiary treatment of skin diseases, rheumatalgia, arthritis, nerve diseases, gynaecologic diseases and cardiovascular diseases.

Owner:伍陆

Traditional Chinese medicine health-care foot bath liquid and preparation method thereof

InactiveCN104069349AAvoid crackingPrevent peelingAntimycoticsAntinoxious agentsDaemonorops dracoCrocus

The invention relates to a traditional Chinese medicine health-care foot bath liquid and a preparation method thereof, and belongs to the traditional Chinese medicine health care field. The traditional Chinese medicine health-care foot bath liquid is characterized by being prepared from the following raw materials in parts by weight: 20-25 parts of folium artemisiae argyi, 18-23 parts of polygala tenuifolia, 20-28 parts of crocus sativus, 15-20 parts of sanguis draconis, 12-18 parts of herba artemisiae scopariae, 20-27 parts of snow lotus herb, 16-20 pars of fructus cnidii, 16-20 pars of cistanche, 13-17 parts of dried alum, 15-20 parts of sophora flavescens, 18-23 parts of fleece-flower root, 13-17 parts of sealwort and 13-17 parts of snakegourd fruit. The traditional Chinese medicine health-care foot bath liquid is capable of sterilizing, invigorating the circulation of blood and moisturizing the skin, and also capable of removing foot diseases such as tinea pedis and beriberi; if all the raw materials are proportionally prepared into the foot bath liquid for soaking feet, the effects of relaxing the muscles and stimulating the blood circulation, refreshing and recovering from fatigue, preventing foot cracking and peeling, and the like can be achieved.

Owner:孙丽君

Process for tinting, dyeing or doping of moulded components made of transparent (co)polyamides in aqueous dye bath

ActiveCN1854386AAttachment is not affectedSynthetic resin layered productsDyeing processStainingMagnifying glass

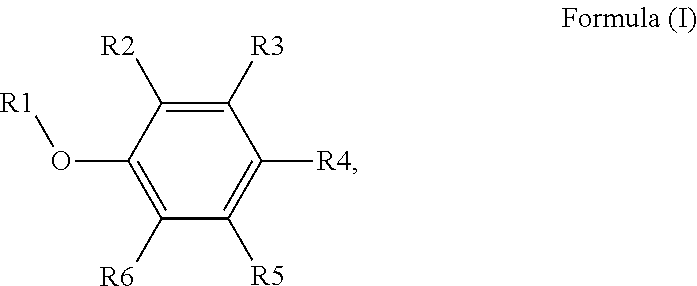

Function bath (A) for toning and / or coloring or doping molded parts comprises (wt.%): deionized water, carrier (0.10-6), surfactant / emulsifier (0.001-1), surface active substance-D (0.01-7, preferably 0.01-6), surface active-substance-E (0.01-3, preferably 0.01-2), pigments or dopants (0.01-0.90), buffer (0-3) and optionally a dispersing agent (0-4) of ethoxy fattyamine ester, aralkylpolyglycol ether or modified polyalcohol for anionic preparation. Function bath (A) for toning and / or coloring or doping molded parts obtained form transparent or translucent (co)polyamide comprises (wt.%): deionized water, carrier (0.10-6), surfactant / emulsifier (0.001-1), surface active substance-D (0.01-7, preferably 0.01-6), surface active-substance-E (0.01-3, preferably 0.01-2), pigments or dopants (0.01-0.90), buffer (0-3) and optionally a dispersing agent (0-4) of ethoxy fattyamine ester, aralkylpolyglycol ether or modified polyalcohol for anionic preparation; where the carrier is monohydroxyglycol, ethyleneglycolmonobutylether or diethyleneglycolmonobutylether, the active substance-D is glycol (preferably diethylene glycol or triethylene glycol), and the active substance (E) contains at least a polyalkyleneglycol (I) of formula (R 1>-{[-O-(CH 2) n] m}OR 2>). R 1>, R 2>H; n : 2-4; and m : 6-35. INDEPENDENT CLAIM is included for: (1) a use of the functional bath in a method for toning and / or coloring or doping molded parts with function additive of transparent or translucent co(polyamide) in water comprising providing immerse bath and / or (A) comprising pigments, doping agent, interference pigment, UV additives, photochromes or thermochrome additives, reinforcing additives for influencing the refraction index; heating the baths at 50-95[deg]C; pretreating the molded part in the bath; purifying the molded part, and removing the purified molded part; immersing (A) in dye or doping agent, color pigments, interfering pigments, UV additives, photo chrome, thermochrome additive or contrast reinforcing additives; removing the molded part from (A) and treating the molded part; and followed by cooling and drying the molded part of at least thermoplastic of transparent (co)polyamide; and (2) toned and / or colored or doped molded part.

Owner:艾曼斯(苏州)工程塑料有限公司

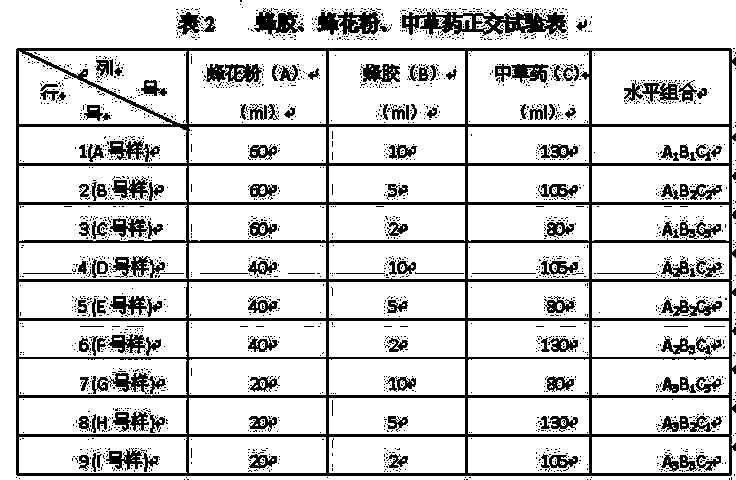

Method for preparing compound foot bath lotion by propolis pollen

InactiveCN103446255ANo side effectsMake up for the singularityAntimycoticsAnthropod material medical ingredientsPropolisPolythylene glycol

The invention relates to a method for preparing a compound foot bath lotion by propolis pollen. The method comprises the following steps: (1) weighing refined propolis, breaking into small blocks, and preparing a propolis ethanol solution by using a specific amount of alcohol; (2) uniformly mixing bee pollen with the alcohol and distilled water, soaking, standing still, extracting supernatant solutions twice, combining the supernatant solutions in a beaker, heating and concentrating in a water bath kettle, and controlling the water temperature to prepare a pollen solution; (3) grinding fructus cnidii, fructus kochiae and fructus xanthii, mixing according to a weight ratio, adding raw water, boiling and filtering;, adding hot water, boiling and filtering; and mixing filtrates to prepare a traditional Chinese medicine solution; (4) carrying out constant-temperature magnetic stirring on polyethylene glycol-400, a propolis solution and Tween-80 in a container, wherein the temperature, the rotation speed and the time are controlled during stirring; clarifying a mixed solution to form a oil phase; adding the bee pollen solution and the traditional Chinese medicine solution, magnetically stirring, cooling the mixed solution, and sub-packaging to prepare the compound foot bath lotion. The compound foot bath lotion has the effects of killing bacteria, relieving itching, clearing heat and toxic materials and the like, and is used for protecting health and treating foot fungal infection diseases.

Owner:GANSU APICULTURE TECH PROMOTION STATION

External traditional Chinese medicine foot bath medicament for treating gout and preparation method thereof

InactiveCN102451287AAchieve healingLower uric acid levelsSkeletal disorderAluminium/calcium/magnesium active ingredientsDiseaseApocynum venetum

The invention relates to the technical fields of an external traditional Chinese medicine foot bath liquid for treating gout and a preparation method thereof, and provides the external traditional Chinese medicine foot bath liquid for treating gout and the preparation method thereof. The external traditional Chinese medicine foot bath medicament for treating gout is prepared from the following traditional Chinese medicine raw materials: dogbane leaf, peganum harmala seed, vernonia anthelmintica, mint leaf, licorice, saussurea involucrata and prepared rehmannia. The external traditional Chinese medicine foot bath medicament for treating gout provided by the invention is clinically verified to have the advantages of effectively lowering uric acid level in blood and reducing patient pain, being practical, convenient and rapid in curative effect, having the efficacies of resolving heat and promoting blood circulation, reducing stagnation and detoxifying, expelling pathogenic wind and dampness as well as dredging collaterals and relieving pain, and realizing the treatment on gout disease.

Owner:乌鲁木齐罗布西坦生物科技有限公司

Traditional Chinese medicinal foot-bath lotion

InactiveCN102451422APromote circulationMultiple therapeutic effectsAntimycoticsAntipyreticMedicinal herbsRemove blood

The invention relates to a traditional Chinese medicinal foot-bath lotion, which contains the following traditional Chinese medicines of: by weight, 20-35 parts of white peony root, 10-20 parts of mulberry leaf, 2-8 parts of cluster cardamom, 5-12 parts of sea-buckthorn, 12-22 parts of cortex acanthopanacis and 10-28 parts of cibotium rhizome. With mutual compatibility of the above medicines, the invention can be used to treat beriberi, promote blood circulation, dispel wind-damp, relieve itching and pain, benefit qi and remove blood stasis, and has more curative effects than a foot-bath lotion prepared by a single medicinal material.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

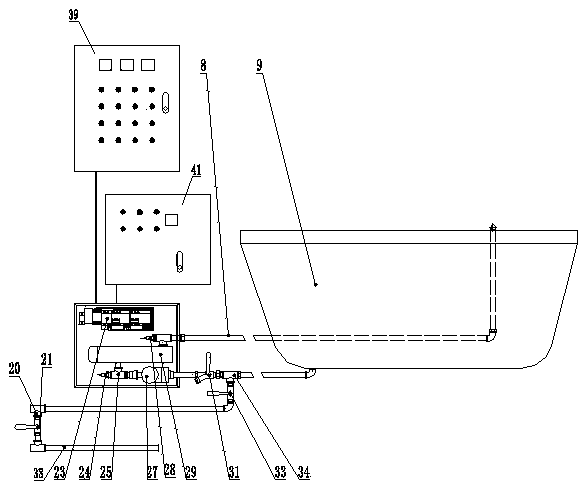

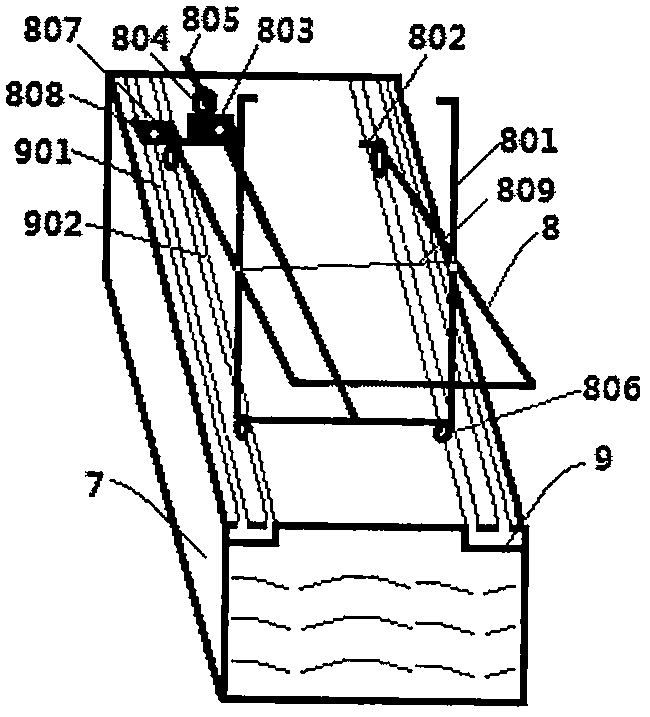

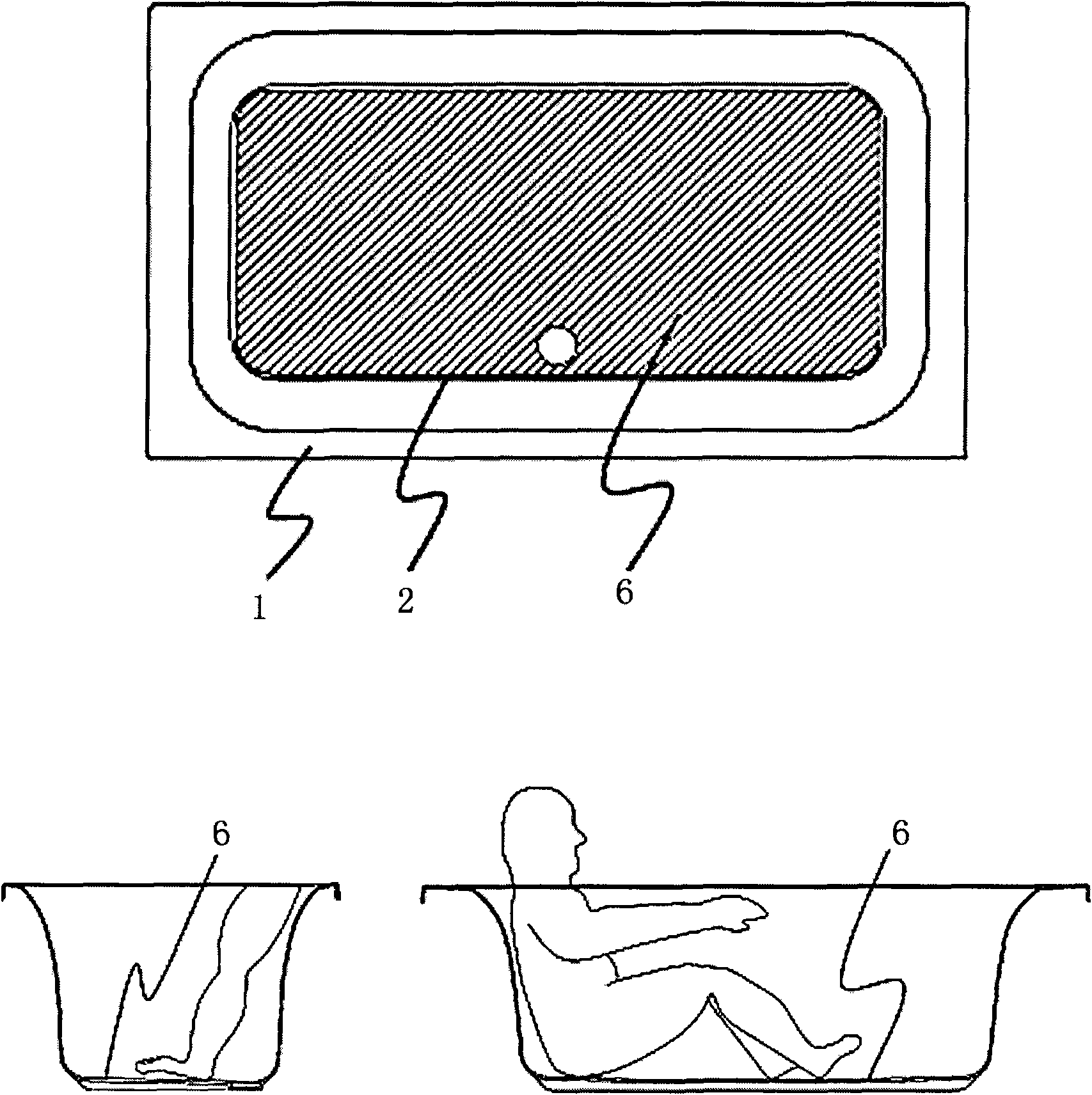

Medicated bath device used for physical exercise and rehabilitation and use method of medicated bath device

ActiveCN106963626ASolve the problem of physical rehabilitation exerciseFree walking exercisePharmaceutical product form changeWalking aidsPhysical medicine and rehabilitationPATIENT PHYSICAL

The invention discloses a medicated bath device used for physical exercise and rehabilitation and a use method of the medicated bath device. The device includes a first lifting device, a transverse sliding device, a medicine container device, a first container, a heating device, a precipitation container, a medicated bath pool, a second lifting device, a sliding groove device and a supporting device; the first lifting device is sleeved with the transverse sliding device, the medicine container device is connected with a third motor, the third motor is connected with a base of a second motor through a fixed plate, and the first container, the precipitation container and the medicated bath pool are connected through pipelines. By means of a supporting device and floating force of water in medicated bath liquid, and the pressure of the body weight of a patient on lower limbs is reduced so that the patient can freely walk in the medicated bath liquid for physical exercise and the purposes of physical exercise and rehabilitation and acne prevention are achieved. The device is safe to use, low in cost, sturdy and durable, can resist slipping and falling, improves the medical-care quality and reduces burdens of doctors and patients.

Owner:李子木

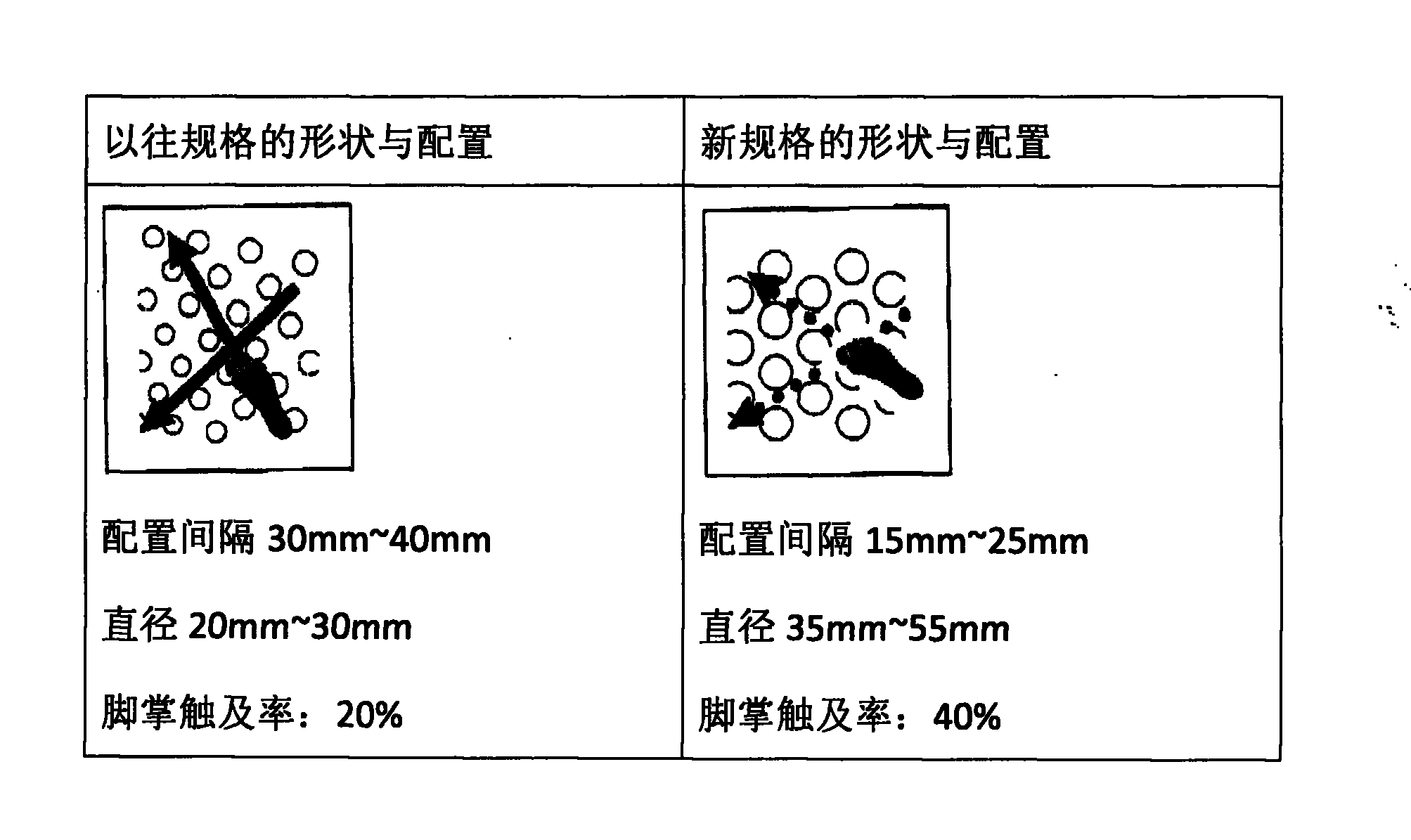

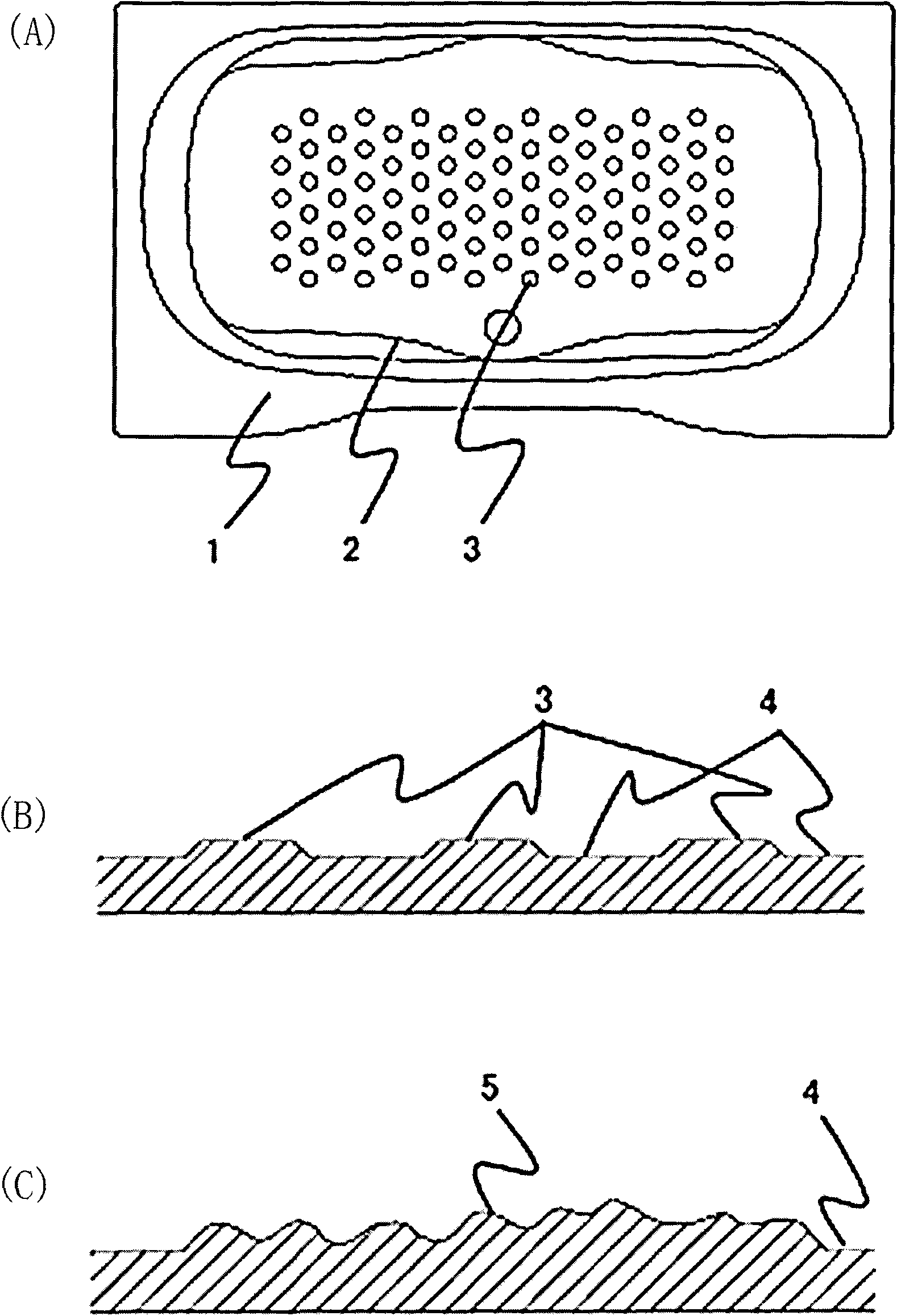

Bathtub

InactiveCN102920370AWith anti-slip effectEasy to removeBathsDouchesStructural engineeringThermal water

Owner:株式会社好适特

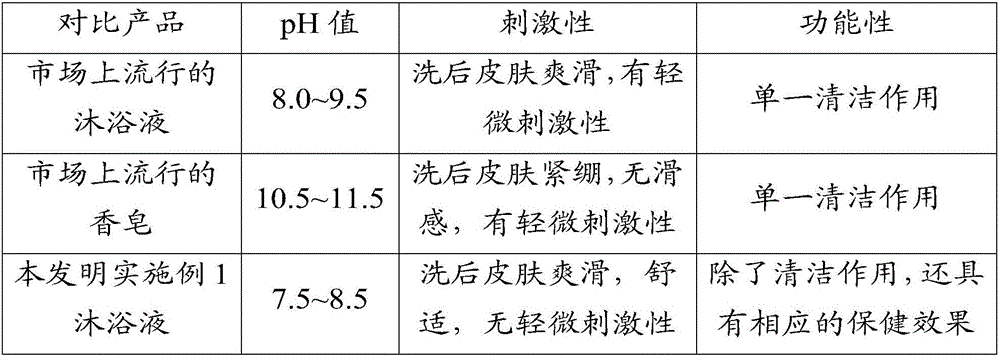

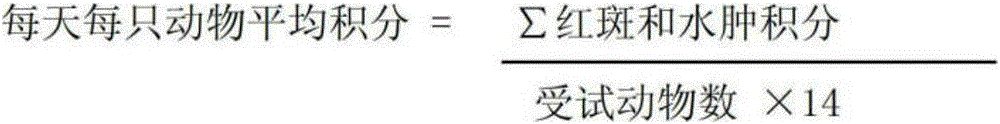

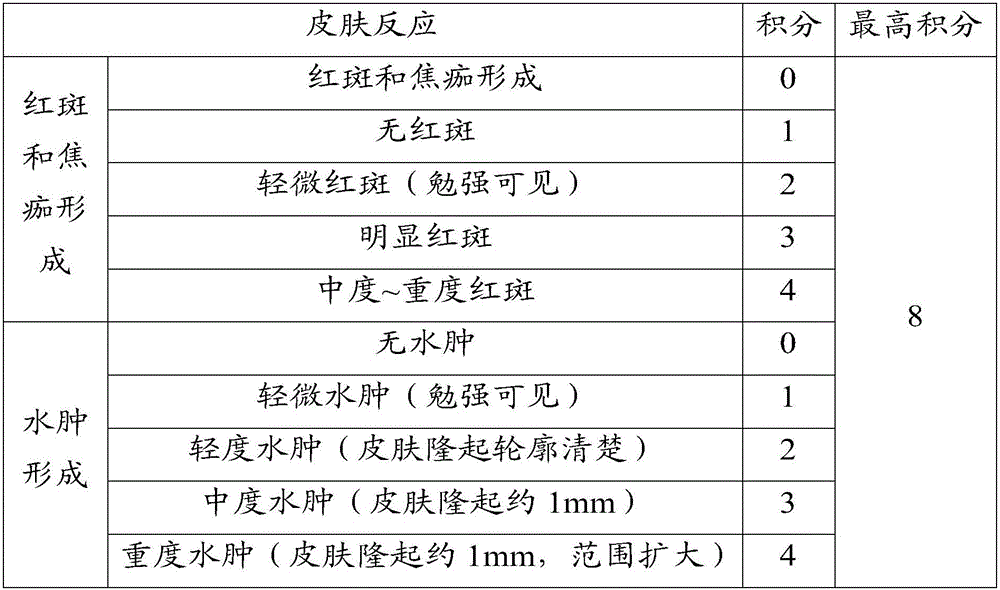

Healthy bath foam and preparation method thereof

InactiveCN105708769AHas health effectsRaw materials are pure and naturalCosmetic preparationsAntipyreticCocamidopropyl dimethylamineIrritation

The invention provides healthy bath foam. The healthy bath foam comprises a bath foam matrix and an effective component, wherein the effective component is prepared from 2-6 parts of Pollia japonica, 1-3 parts of orchids, 5-10 parts of asarum forbesii Maxim, 40-50 parts of dahurian angelica root, 10-15 parts of common aucklandia root, 40-50 parts of Acorus calamus, 10-15 parts of fortune eupatorium herb, 1-3 parts of roses, 1-3 parts of cloves, 1-3 parts of peonies, 1-3 parts of Chinese roses and 5-10 parts of rosa multiflora through extraction; the bath foam matrix is prepared from fatty alcohol polyoxyethylene ether ammonium sulfate, cocamidopropyl dimethylamine oxide, coconut fatty acid diethanol amide, citric acid and deionized water. A preparation method of the healthy bath foam comprises the steps that the effective component is extracted and concentrated into thick paste, the thick paste is mixed with the bath foam matrix, the obtained mixture is subjected to sterilization and sub-packaging, and a finished product of the bath foam is obtained. The healthy bath foam is anti-bacterial and anti-inflammatory, has little irritation, is fragrant, and has functions of dispelling dampness, resolving toxicity and whitening skin.

Owner:周常

Lying-in woman recovery bath liquid and production method

InactiveCN104435131ANo side effectsMeet healthPharmaceutical delivery mechanismSexual disorderCassiaAngelica Sinensis Root

The invention discloses lying-in woman recovery bath liquid. The lying-in woman recovery bath liquid is mainly prepared by taking baeckea frutescens, suberect spatholobus stem, cassia twig, Chinese mugwort leaves and Chinese angelica roots as raw materials by virtue of refining. The lying-in woman recovery bath liquid can be used for removing toxicity and protecting the body, widening muscles and removing tiredness, activating blood and dissolving stasis, and removing dirtiness and updating for postpartum women. The product disclosed by the invention is delicately fragrant in smell and mild in performance, cannot cause irritation to the skins, and is especially suitable for postpartum women.

Owner:莫兆钦

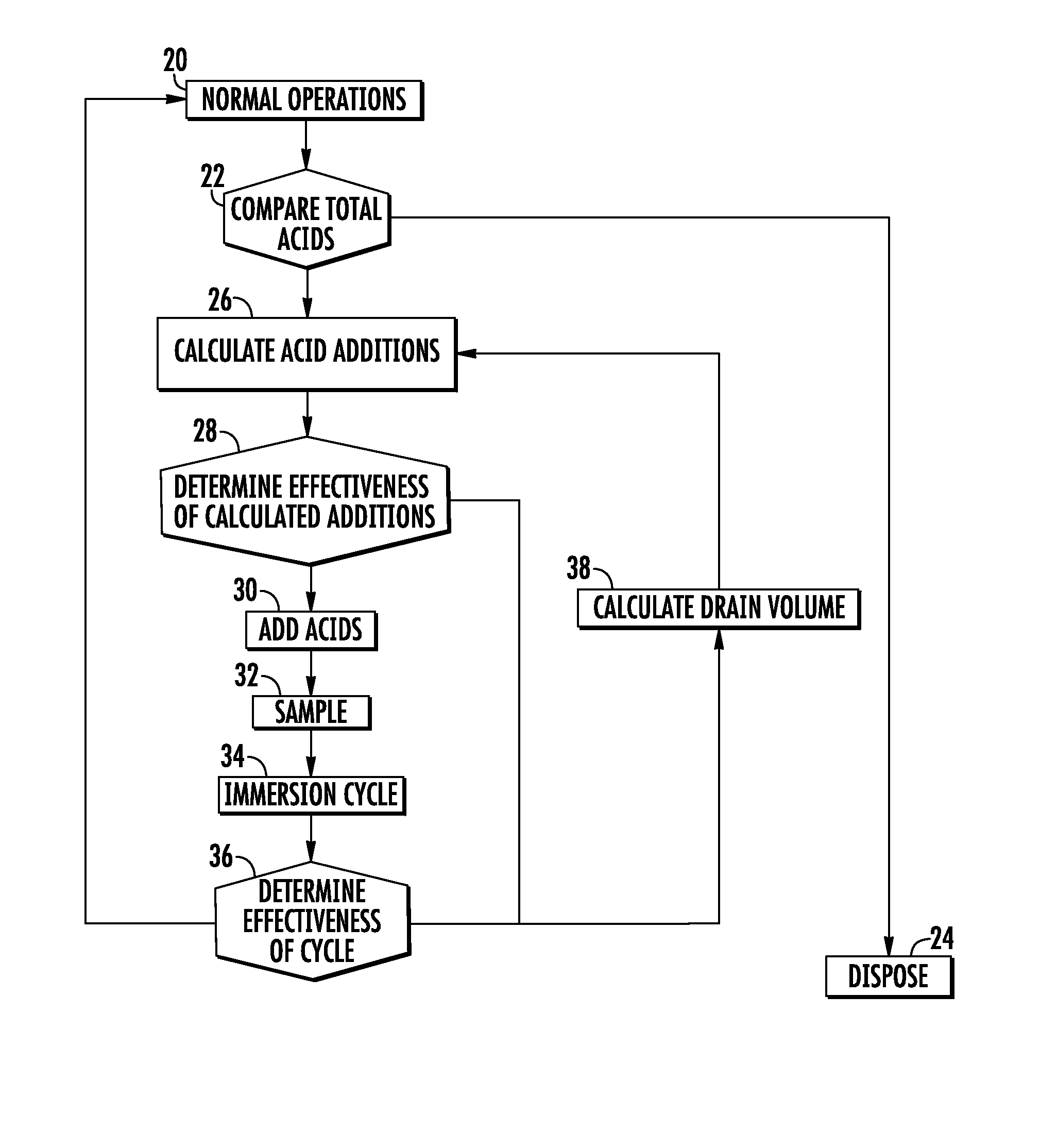

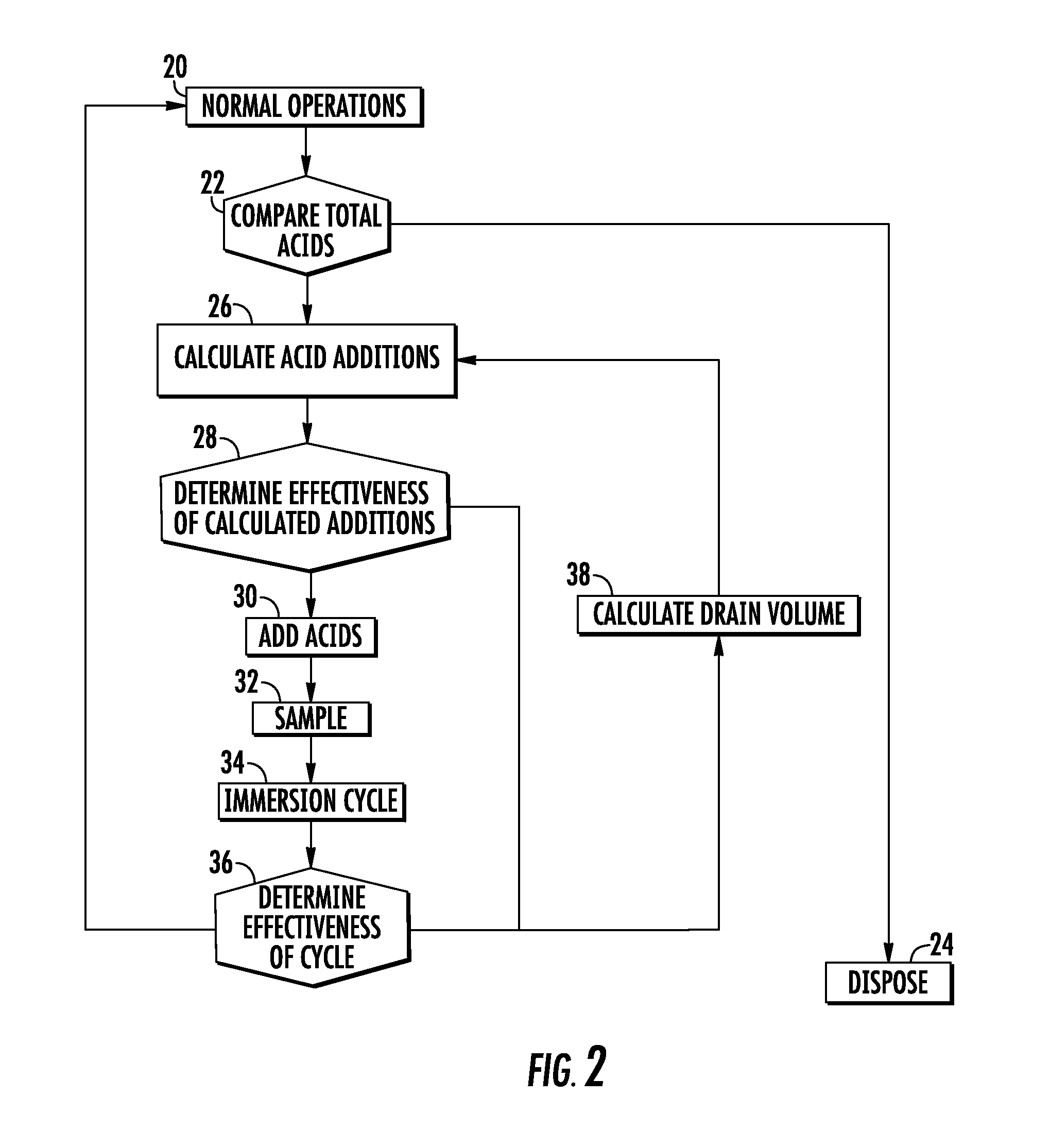

Method for refreshing an acid bath solution

InactiveUS8877084B2Decorative surface effectsSemiconductor/solid-state device manufacturingPhosphoric acidChemistry

A method for refreshing an acid bath solution includes determining a concentration of phosphoric acid in the acid bath solution and determining a concentration of hydrochloric acid in the acid bath solution. The method further includes calculating a volume of phosphoric acid to add to the acid bath solution to achieve a predetermined concentration of phosphoric acid in the acid bath solution. In addition, the method includes calculating a volume of hydrochloric acid to add to the acid bath solution with the volume of phosphoric acid to increase the acid bath solution to a predetermined volume, and adding the volume of phosphoric acid and the volume of hydrochloric acid to the acid bath solution.

Owner:GENERAL ELECTRIC CO

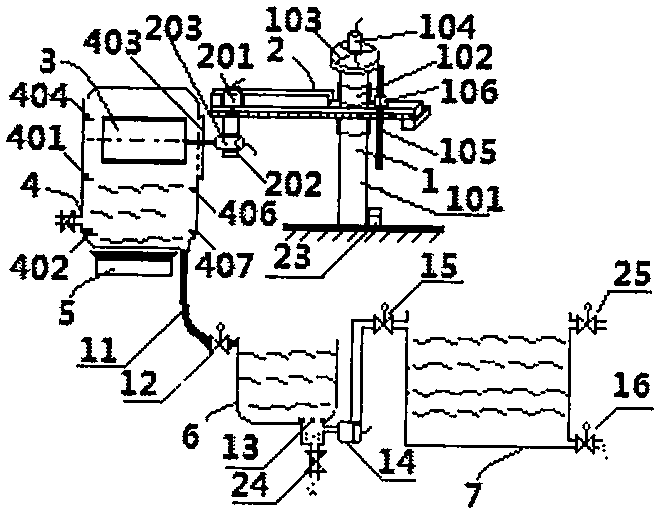

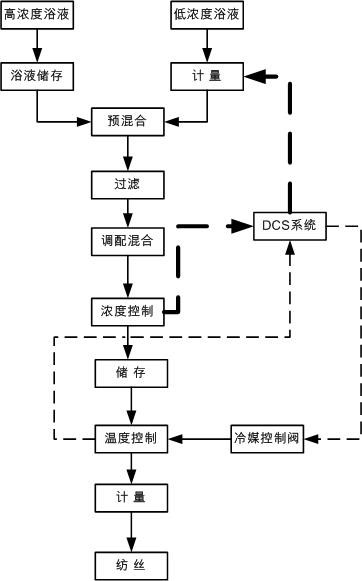

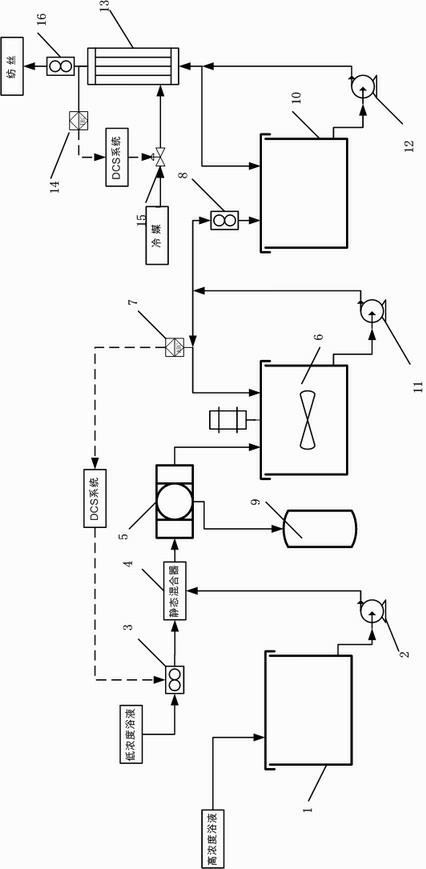

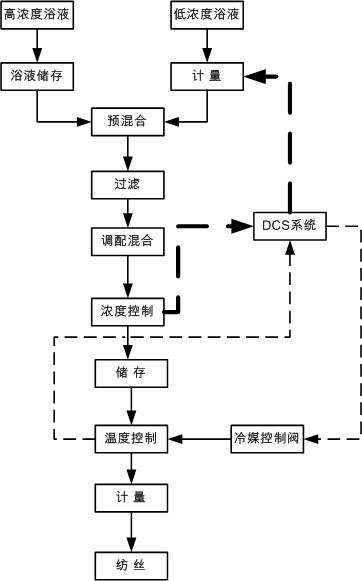

Continuous treatment device and method suitable for high-flow meta-position aramid spinning bath lotion

ActiveCN102660782ASuitable for continuous productionControl concentration changesSpinning head liquid feederSpinning solutions preparationYarnSpinning

The invention relates to a continuous treatment device and a continuous treatment method which are suitable for high-flow meta-position aramid spinning bath lotion. According to the key point, the continuous treatment device consists of a bath lotion receiving tank, a bath lotion delivery pump, a static mixer, a bath lotion blending tank, a bath lotion filtering machine, a bath lotion storage tank and a bath lotion condition control device, and is characterized in that high-concentration bath lotion enters the receiving tank from spinning yarns, and is premixed with low-concentration bath lotion in the static mixer; and the premixed bath lotion is filtered by the centrifugal filtering machine, and the filtered bath lotion is mixed uniformly, subjected to heat exchange and metered, and enters a spinning system. The spinning bath lotion prepared by the method is stable in concentration and temperature and low in content of impurities, and can meet the requirements of a spinning process and stable production.

Owner:上海舟汉纤维材料科技股份有限公司

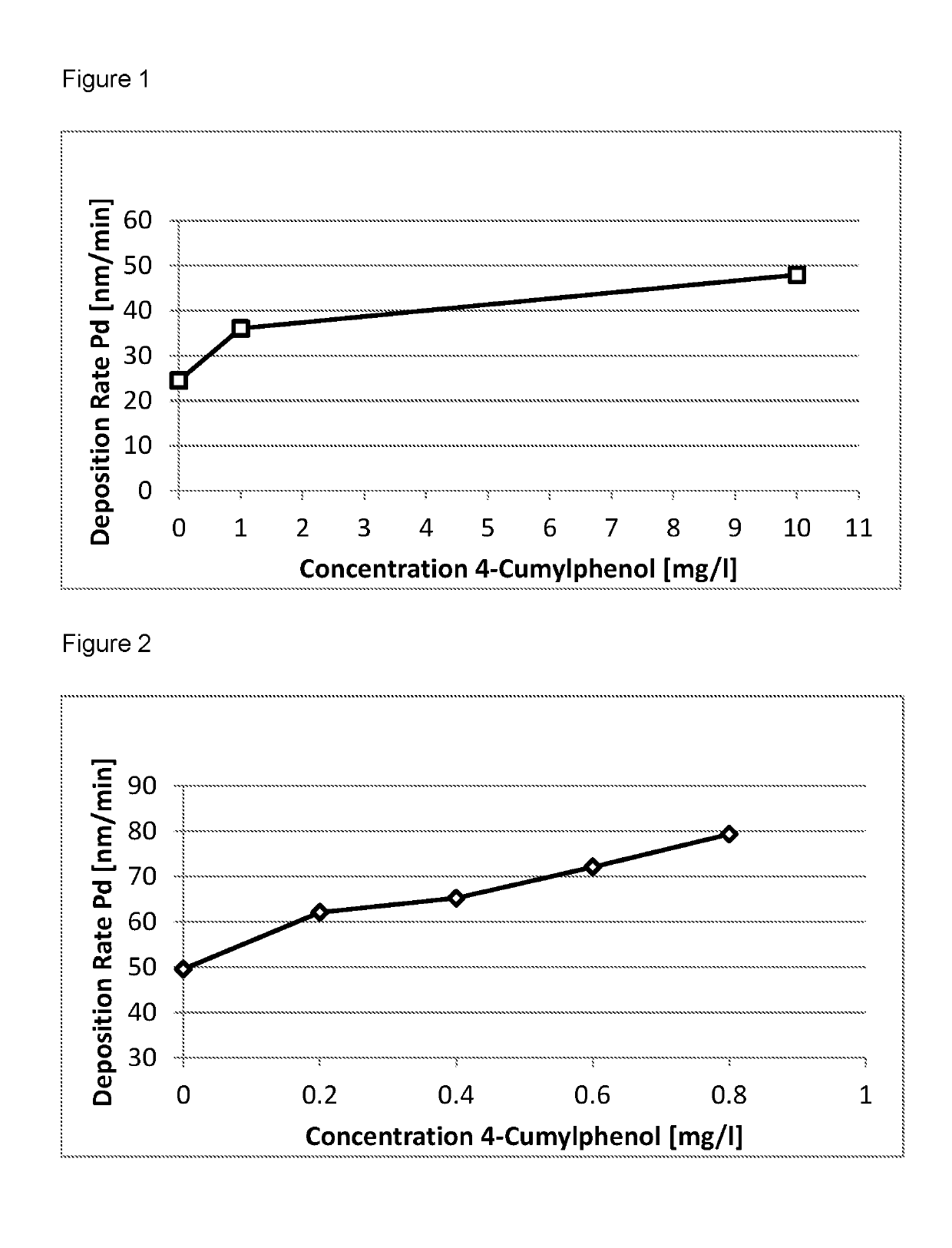

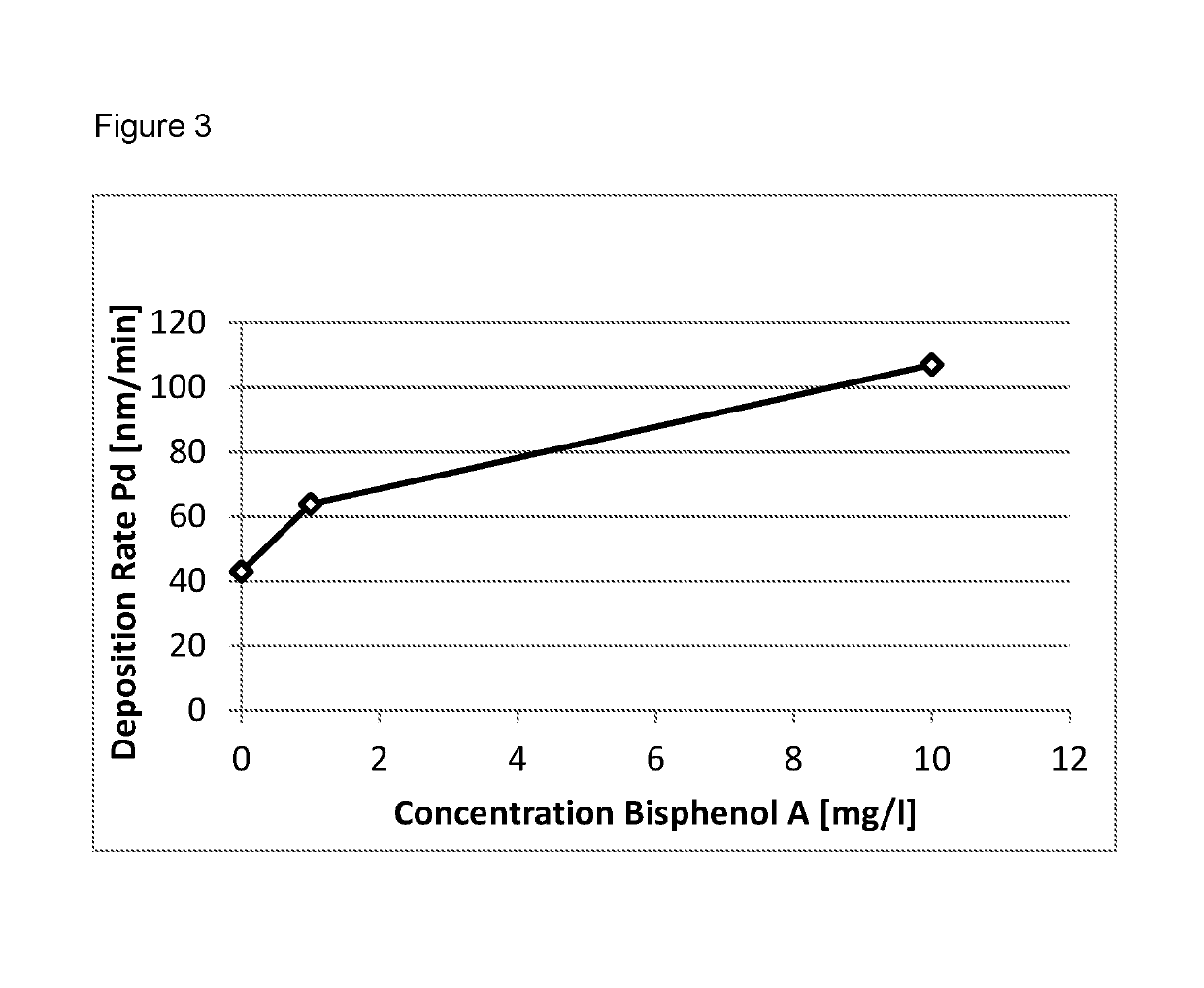

Plating bath composition and method for electroless plating of palladium

ActiveUS10385458B2Extended service lifeIncrease deposition rateLiquid/solution decomposition chemical coatingLife timePalladium ion

Owner:ATOTECH DEUT GMBH

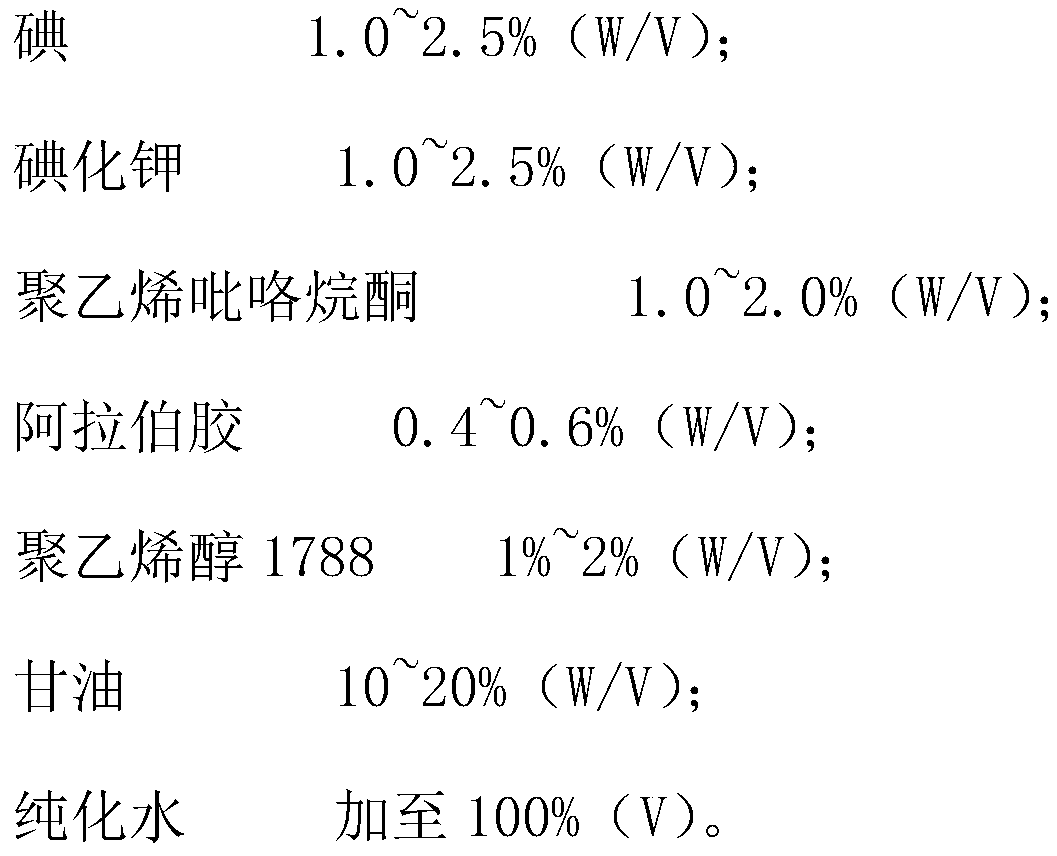

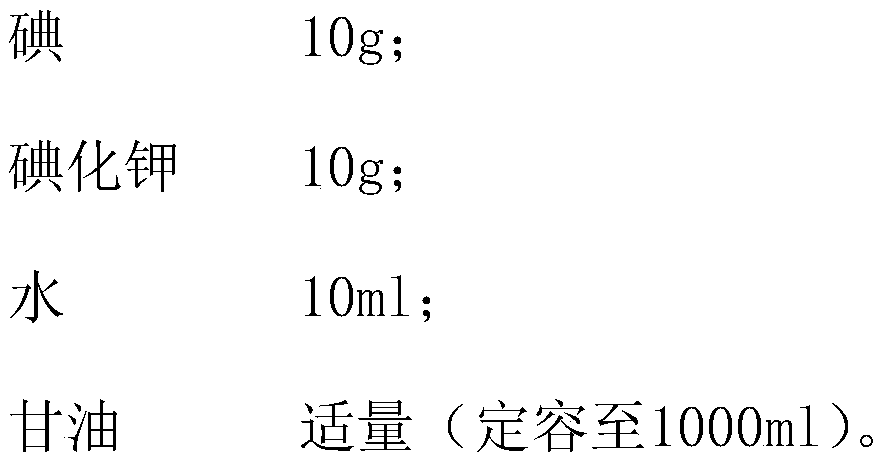

Iodine glycerin nipple infusion and preparation method thereof

InactiveCN110711204AImprove dissolution rateReduce wasteAntibacterial agentsAntisepticsPolyvinyl alcoholMilk cow's

The invention belongs to the field of veterinary drug preparations, and particularly relates to an iodine glycerin nipple infusion special for dairy cattle nipples and a preparation method thereof. The iodine glycerin nipple infusion is prepared from iodine, potassium iodide, polyvinylpyrrolidone, Arabic gum, polyvinyl alcohol, glycerinum and purified water. According to the novel iodine glycerinnipple infusion and the preparation method thereof, the adsorbability of liquid medicine to skin is increased, in using of the soups, the phenomenon of liquid medicine dropping cannot occur, the liquid medicine can be well absorbed on the surface of the skin to form a layer of protective films, the using efficiency of the liquid medicine is greatly improved, and the bactericidal effect of medicated bath solutions is better met. At present, iodine glycerin nipple infusion is not reported by other patents and documents.

Owner:河北远征药业有限公司 +1

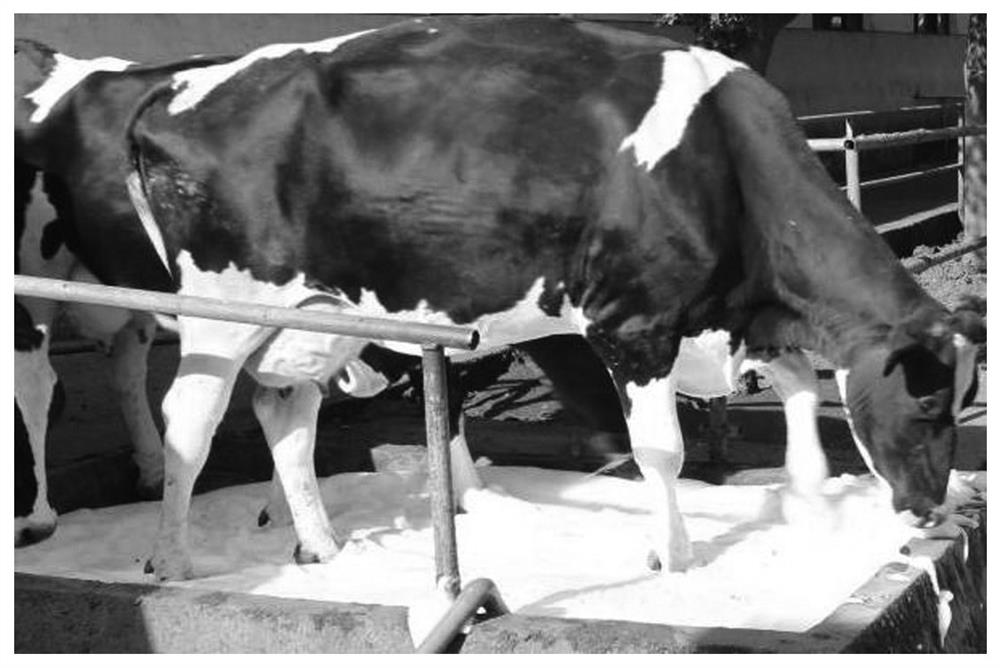

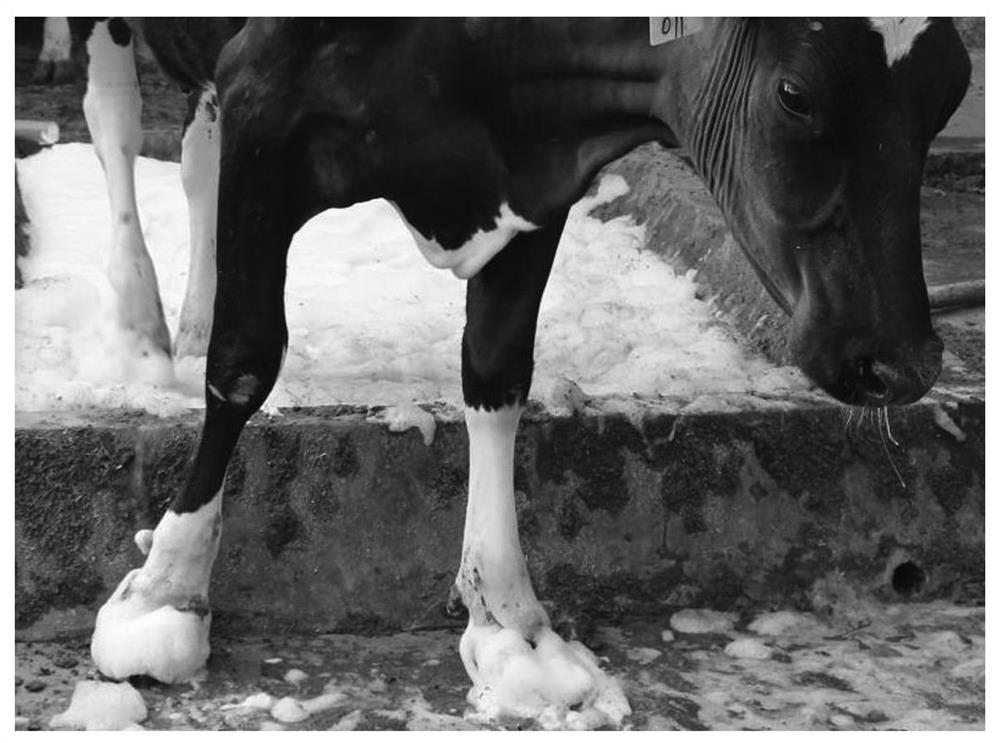

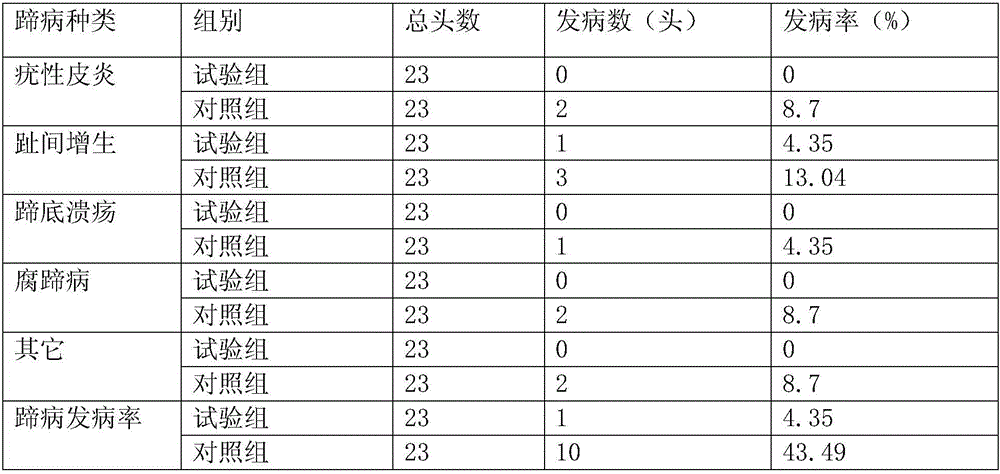

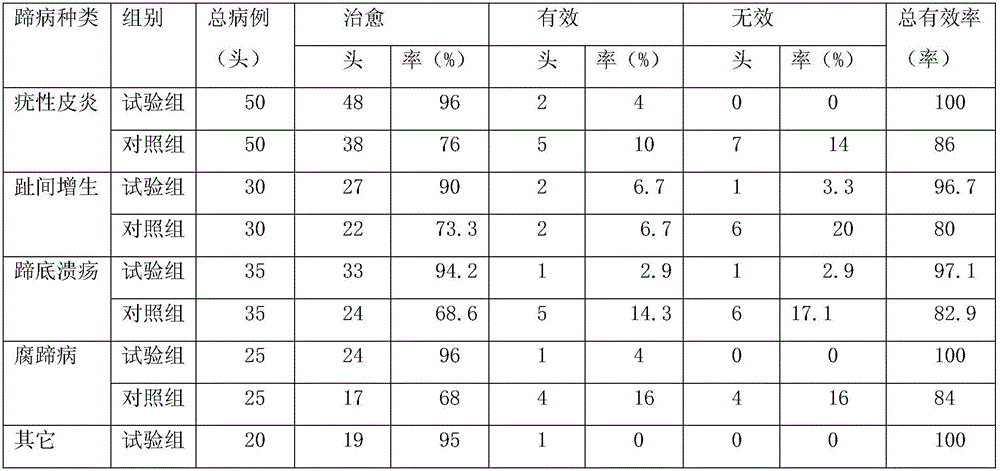

Foam type hoof bath lotion for daily prevention and treatment of animal hoof diseases, and preparation method and application thereof

InactiveCN111407789APrevent persistent infectionAvoid infectionAntibacterial agentsInorganic active ingredientsBiotechnologyFoaming agent

The invention belongs to the field of veterinary disinfectants, and discloses a foam type hoof bath lotion for daily prevention and treatment of animal hoof diseases, and a preparation method and application thereof. The hoof bath lotion comprises, by weight, 0.2-0.4 part of a salt sterilizing hoof care agent, 1-2 parts of an antibacterial plant extract, 0.5-2 parts of a foaming agent, 0.5-5 partsof a foam stabilizer and 1-2 parts of a toner. The preparation method comprises the following steps: preparing a salt sterilizing hoof care agent solution I; preparing a toner solution II; preparinga mixed solution III of the foaming agent and the foam stabilizer; adding the solution II and the solution III into the solution I to form a solution IV; preparing a plant extract solution V; adding the solution V into the solution IV to form a solution VI; and adjusting the pH value of the solution VI, fixing the volume of the solution VI, and carrying out inspecting to obtain the foam type hoofbath lotion for daily prevention and treatment of animal hoof diseases. The foam type hoof bath lotion of the invention can be used for preventing and treating hoof diseases, has the advantages of high cure rate, mild action, favorable bactericidal effect, obvious environmental protection advantage, low consumption and simple techniques, reduces use cost, and presents wide application prospects.

Owner:HENAN KANGXING PHARMA +1

Rose foot bath liquid and preparation method thereof

InactiveCN103550338AAvoid pollutionAvoid wastingSalicyclic acid active ingredientsAntimycoticsPhysical therapyBiology

The invention relates to rose foot bath liquid and a preparation method thereof. The rose foot bath liquid consists rose residue liquid or adopts the rose residue liquid as a main component; the rose residue liquid is a reminding solution after essential oil is extracted from roses. The foot bath liquid and the preparation method have the advantages that the rose residue liuid, namely, the reminding solution after the essential oil is extracted from the roses, as the foot bath liquid or is used as the main component for utilization, so that the pollution to the environment and the waste of resources due to direct discharge are avoided; in addition, the foot bath liquid not only can be used for preventing and treating the pedopathy effectively, but also can be used for refreshing the nerve, recovering the fatigue and moisturizing the skins of the foot.

Owner:GANSU DONGFANG TIANRUN ROSE TECH DEV CO LTD

Preparation method of water-washing-free sponge bath liquid

InactiveCN106176334ALess irritatingNon-toxicCosmetic preparationsHair cosmeticsWater bathsAdditive ingredient

The patent of the present invention discloses a method for preparing a water-free scrub bath liquid. Based on the total weight, every 100g of the bath liquid includes the following components by weight: 2-15g of anionic surfactant, 0.5-10g of amphoteric surfactant , 0.1-6g of moisturizing agent, 0.005-0.035g of preservative, 0.3-0.8g of fragrance, 0.05-0.15g of vitamin E, 0.5-1.5g of aloe extract, and adjust the pH value of the above ratio to 5-7 range of citric acid, and the rest of the weight components are deionized water. The preparation method of the water-free scrub bath liquid of the present invention has the characteristics of low irritation, non-toxicity, low residue and high biodegradability, cleansing and skin care, and does not need to be rinsed with water after use. It is suitable for patients, mountaineering, polar inspections, navigation, It is simple and convenient to use in special environments such as aerospace and other special environments where water supply is difficult, the environment is harsh, the human body and hair are easily dirty, and it is difficult to take a bath with water.

Owner:TIANJIN SIBANGSHI BIOTECH

A kind of environmental protection composite foam foot bath liquid and preparation method thereof

ActiveCN108836938BExtended stability timeIncrease profitInorganic active ingredientsAntisepticsBiotechnologyFoaming agent

The invention belongs to the technical field of animal medicated bath liquid, and specifically discloses an environment-friendly composite foam hoof bath liquid and a preparation method thereof, comprising the following components: 1-20 parts of glutaraldehyde, 1-20 parts of quaternary ammonium salt, nano-silver 0.1-0.3 parts of single, 1-15 parts of foaming agent, 0.5-5 parts of foam stabilizer, 8-10 parts of polyol, 0.1-0.6 parts of pigment, 10-30 parts of deionized water; It remains stable and does not freeze in a low temperature environment, which is conducive to the use and storage of hoof bath liquid. The bactericidal ingredients contained in it stay in the affected area for a longer time, slowly penetrate into the toes of animals, and directly act on the affected area, effectively killing germs .

Owner:陕西汉隆清洁消毒产品有限公司

Radix aconiti foot bath lotion with effects of dispelling wind and eliminating dampness as well as warming channels for stopping pain and preparation method of radix aconiti foot bath lotion

InactiveCN104436025APromote absorptionEnhance physical fitnessNervous disorderAnthropod material medical ingredientsRadix AconitiCymbopogon

The invention discloses a radix aconiti foot bath lotion with effects of dispelling wind and eliminating dampness as well as warming channels for stopping pain and a preparation method of the radix aconiti foot bath lotion. The radix aconiti foot bath lotion is characterized by being prepared from the following raw materials in parts by weight: radix aconite, rosin, blister beetles, rhizoma cibotii, radix saposhnikoviae, herba artemisiae anomalae, flos campsis, curcuma longa, cymbopogon plant essential oil, orchid plant essential oil and geranium plant essential oil. The radix aconiti foot bath lotion comprises the following processes of selecting; decocting; purifying; perfuming; and packaging to obtain a finished product. According to the foot bath lotion disclosed by the invention, the traditional Chinese medicines are combined with the essential oils, so that the beneficial effects of foot bath to a human body are improved, meanwhile, the beneficial effects of the essential oils to the human body are also achieved, various effects are additionally provided, and the market is expanded. Due to the nourishing effects of the traditional Chinese medicines, the effects of dispelling wind and eliminating dampness as well as warming channels for stopping pain are achieved, and the absorbing ability of the human body is enhanced; in addition, the essential oils are assisted to regulate the human body, and the human body is simultaneously nourished by using the traditional Chinese medicines and the essential oils, so that the effects of dispelling wind and eliminating dampness as well as warming channels for stopping pain are enhanced, the physique of the human body is enhanced, the fragrance is increased, the immunity of the human body is enhanced, and the body fatigue is relieved; and the radix aconiti foot bath lotion is beneficial to sleeping or refreshing.

Owner:HARBIN LINGCAOSHU BIOLOGICAL TECH

Mongolian medicinal bath liquid for treating rheumatic arthritis and preparation method of Mongolian medicinal bath liquid

InactiveCN110604753ATreatment helpsShort course of treatmentHeavy metal active ingredientsAntipyreticSide effectArthritis

The invention relates to the technical field of medicaments for treating rheumatic arthritis, and discloses a Mongolian medicinal bath liquid for treating rheumatic arthritis and a preparation methodof the Mongolian medicinal bath liquid. The prescription of the Mongolian medicinal bath liquid is composed of myricaria bracteata, sabina chinensis leaves, gaultheria forrestii, herba ephedrae, and artemisia frigida willd. According to the Mongolian medicinal bath liquid for treating the rheumatic arthritis, the treatment course for treating the rheumatic arthritis is short, different additionalsymptoms are targeted, the corresponding auxiliary medicinal bath prescription is used in the Mongolian medicinal bath liquid for treating the rheumatic arthritis, the treatment of the rheumatic arthritis is helped, the improvement of pain symptoms is obvious, the treatment efficiency is high, the toxic side effects do not exist, the drug resistance phenomenon does not exist, the operation is easyand convenient, safety is realized, the cost is low, relapse after the treatment is unlikely, and pain can be effectively relieved for patients.

Owner:XINJIANG MEDICAL UNIV +1

Foot-bath lotion and its preparation method

InactiveCN102451119AHigh content of active ingredientsHigh content of ingredientsCosmetic preparationsToilet preparationsPropanoic acidSucrose distearate

The invention relates to a foot-bath lotion and its preparation method, specifically relates to the foot-bath lotion for pouring in feet washing water. The foot-bath lotion comprises the following raw materials: 45-68 parts of polypropylene glycol-2-sodium laurylsulfate, 14-30 parts of oat flour, 10-25 parts of stearic acid sucrose ester, 22-36 parts of glyoxal solution and 6-18 parts of fruit acid. The provided foot-bath lotion is liquid, and has high effective ingredient content; the foot-bath lotion has the functions of antiperspirant, sterilization and deodorization when being added in hot water used for washing feet, the foot-bath lotion is in the liquid state, therefore no dust pollution is generated, waste caused by flying dust is not existed, and the usage The provided foot-bath lotion is liquid, and has high effective ingredient content; the foot-bath lotion has the functions of antiperspirant, sterilization and deodorization when being added in hot water used for washing feet, the foot-bath lotion is in the liquid state, therefore no dust pollution is generated, waste caused by flying dust is not existed, and the usage cost is reduced.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

Bath lotion for pets and preparation method thereof

ActiveCN104688892AGood treatment effectItching Prevention and TreatmentHydroxy compound active ingredientsAntipyreticMentholTraditional medicine

The invention provides a bath lotion for pets. The bath lotion is used for preventing and treating pet eczema and contains Chinese traditional medicine extracts. The Chinese traditional medicine extracts contain radix sophorae flavescentis, golden cypress, honeysuckle, fructus kochiae, rhizoma atractylodis, golden larch bark, menthol and other constituents. After being extracted and refined, the bath lotion is used in cooperation with a common bath lotion and has the obvious effects of inhibiting bacteria, killing pests, clearing heat and nursing the pets. The bath lotion, containing the Chinese traditional medicine extracts, for the pets has the good effects of preventing and treating pet eczema, scytitis and pruritus. The bath lotion is good in clinical application effect, low in cost and free of residues and has broad market prospects.

Owner:QINGDAO AGRI UNIV

Deashing-softening-pickling integrated clean tanning method and application thereof

ActiveCN113913563AFix stability issuesSettle the priceTanning treatmentPre-tanning chemical treatmentMetallurgySalt free

The invention provides a deliming-softening-pickling integrated clean tanning method, which is characterized in that deliming, enzyme softening and pickling processes in a conventional tanning process are combined, and salty pickling is replaced by salt-free pickling. The method comprises the following steps: adjusting the pH value of limed bare skin to be acidic by using an ammonium-salt-free dealkalizing agent and non-expansive acid, adding an acidic compound enzyme preparation for softening, and adding the non-expansive acid for salt-free pickling in one bath, so as to achieve the purposes of softening and pickling at the same time. According to the method, conventional pancreatin softening is replaced with acidic compound enzyme softening, ammonium salt, boric acid and neutral salt are completely not added, ammonia nitrogen and chloride ion pollution in the procedures of deliming, softening and pickling can be eliminated from the source, and chromium emission can be reduced; the method can effectively avoid the problem of unstable softening effect caused by poor pH buffering property of the conventional ammonia-free softening bath lotion. The method has wide practicability and is suitable for various leather production processes taking various animal skins as raw materials.

Owner:SICHUAN UNIV

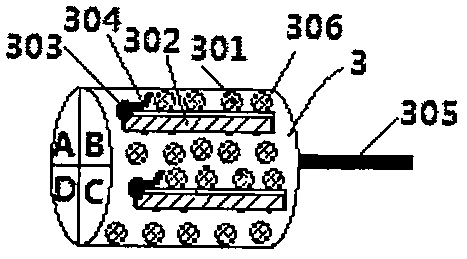

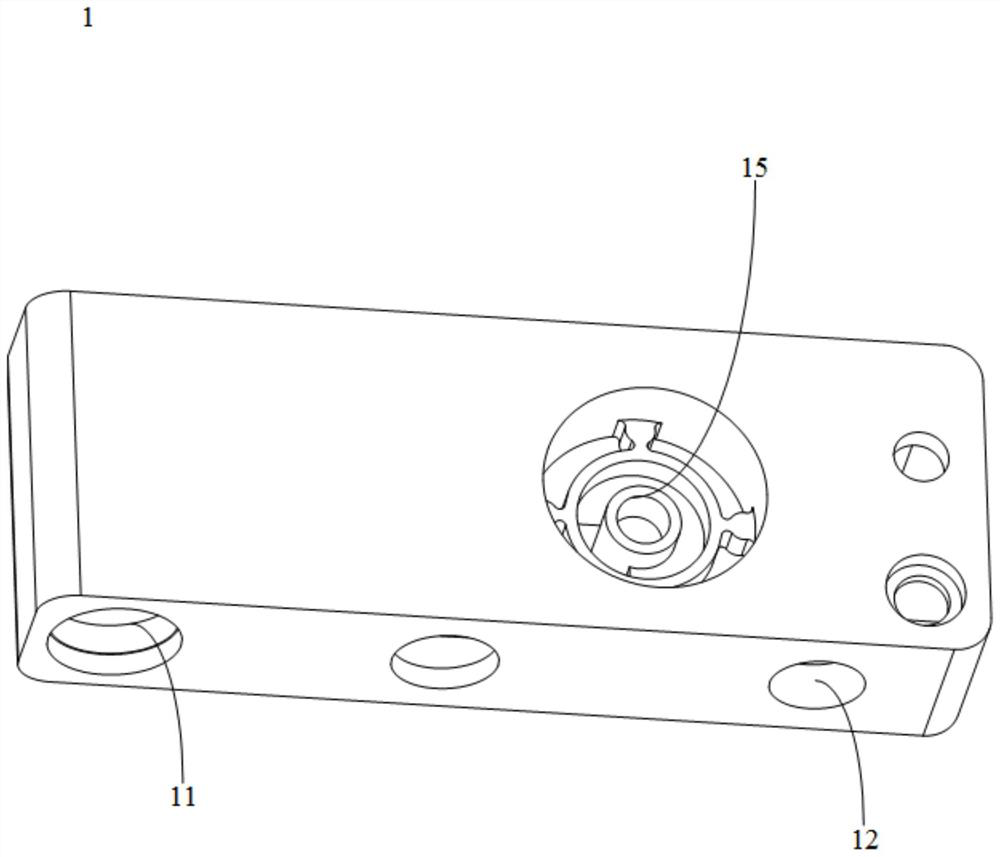

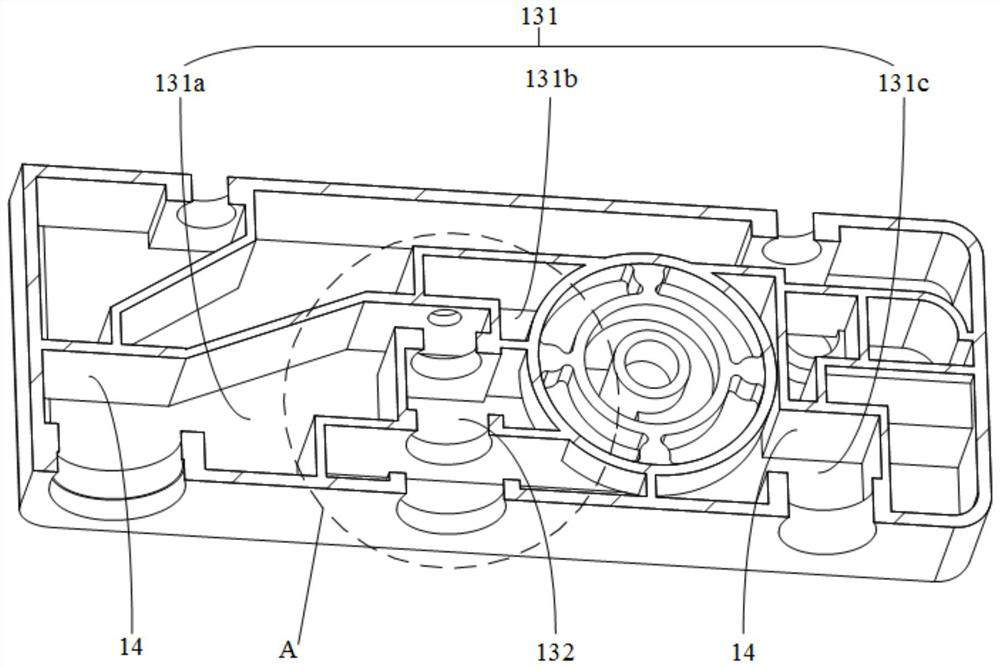

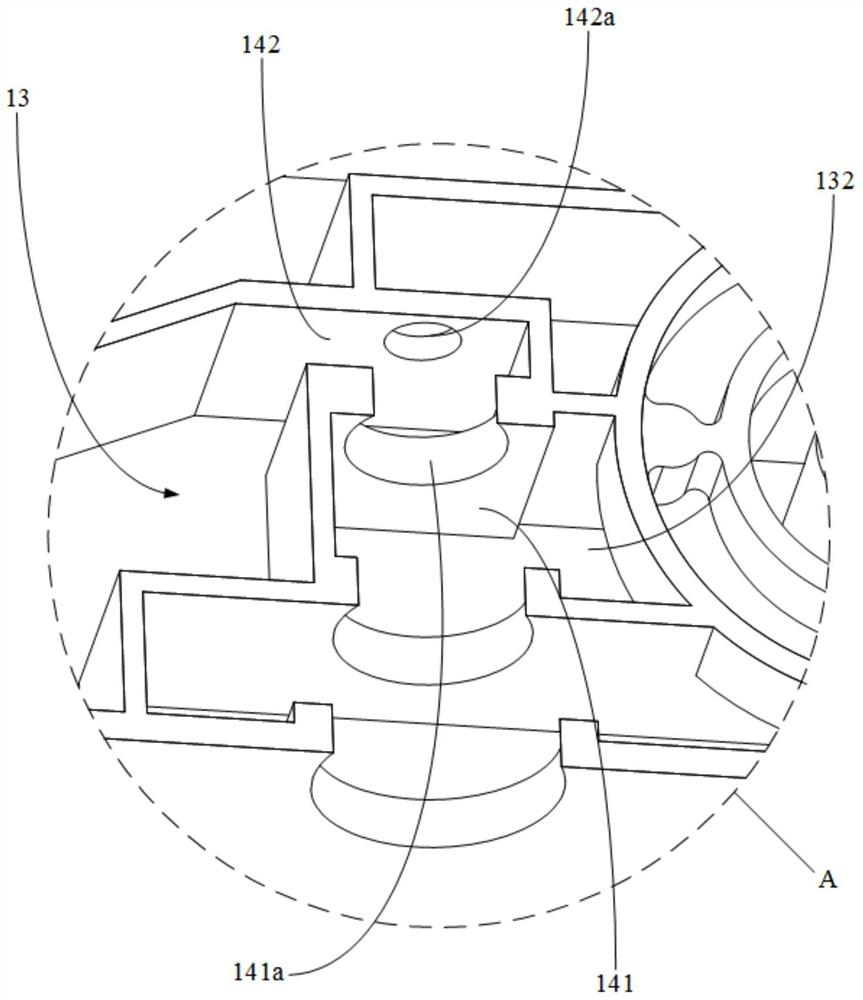

Central control waterway component, bathing system and control method of central control waterway component

PendingCN111877467ATo achieve diversionImprove convenienceDomestic plumbingPipe waterEnvironmental engineering

The invention discloses a central control waterway component, a bathing system and a control method of the central control waterway component. The central control waterway component comprises a waterway component, a bath lotion filter flask and a switcher, wherein the waterway component comprises a water inlet structure, a water outlet structure and a waterway pipeline; the waterway pipeline comprises a main waterway of which two ends are connected with the water inlet structure and the water outlet structure respectively, and a branch waterway of which two ends are connected to the main waterway; a water-melting bath lotion substance is placed in the bath lotion filter flask, the bath lotion filter flask is mounted on a waterway component, and a bath lotion filter cavity communicates witha water distribution path; and the switcher is mounted on the waterway component and is located at the intersection of the main waterway and the branch waterway so as to selectively control the wateroutlet structure to output clear water or bath lotion. According to the technical scheme, a user can conveniently and independently select the water outlet structure to output clean water or bath lotion in the bathing process, and the bathing convenience of the user is improved.

Owner:杨钟雄

Dairy cow hoof bath foam without antibiotics and preparation method thereof

InactiveCN105748387AHigh transparencyReduce the cost of farmingAntibacterial agentsCosmetic preparationsBiotechnologyMilk cow's

The invention discloses dairy cow hoof bath foam without antibiotics. Chinese herbal medicine extracts capable of effectively killing and inhibiting dairy cow hoof disease infectious pathogenic bacteria, promoting hoof wound healing, effectively preventing and curing various hoof diseases, and improving dairy cow autoimmunity and premunition, and aloe extracts with strong cohesiveness capable of promoting medicated permeation and effectively repairing cuticula are adopted as main raw materials; plant extracts capable of changing dairy cow hoof cuticula structures and promoting the effective components such as Chinese herbal medicine and aloes to quickly penetrate into skin deep layer to absorb are added; ultrasonic dispersion, dissolution, high pressure homogenization and cooling-heating treatment technologies are combined organically, not only are modified dietary fibers with efficient bonding forces compounded scientifically, but also trehalose, albumen, natural antioxidant and the like capable of protecting effective constituents of components against oxidization and improving the physical and chemical stability of hoof care mist spray are added, and finally, the hoof bath foam with strong stability, safety, high efficiency, and no any antibiotics and toxic chemicals is obtained.

Owner:YIWU JUHUI BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com