Antibacterial antiviral treating agent, preparation method and application thereof

A treatment agent and anti-virus technology, which is applied in the field of antibacterial and antiviral treatment agents and high-efficiency antibacterial and antiviral treatment agents. It can solve the problems of affecting the spinning process, poor antibacterial and antiviral performance, and ordinary mask filtration performance cannot be solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

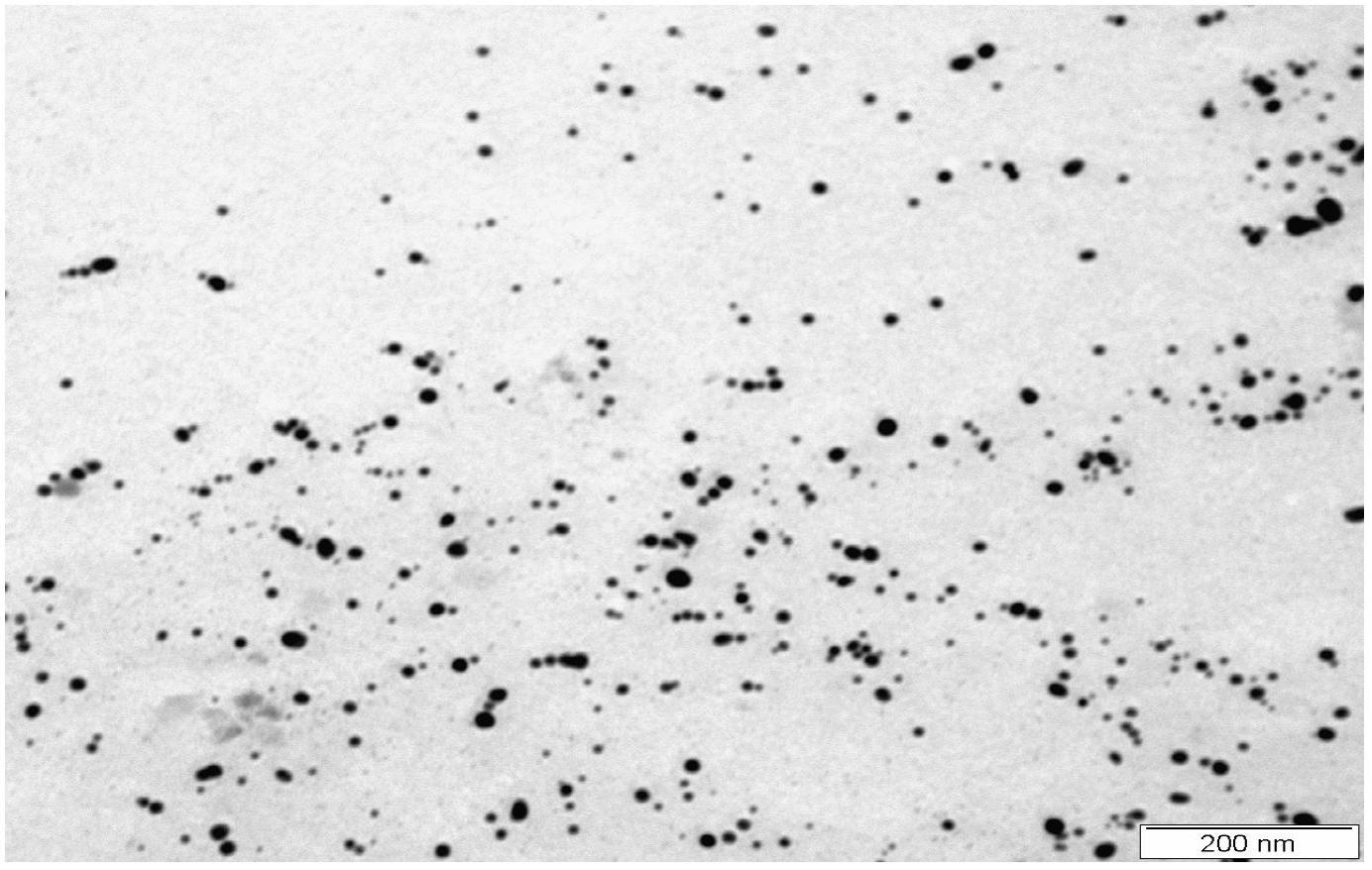

Image

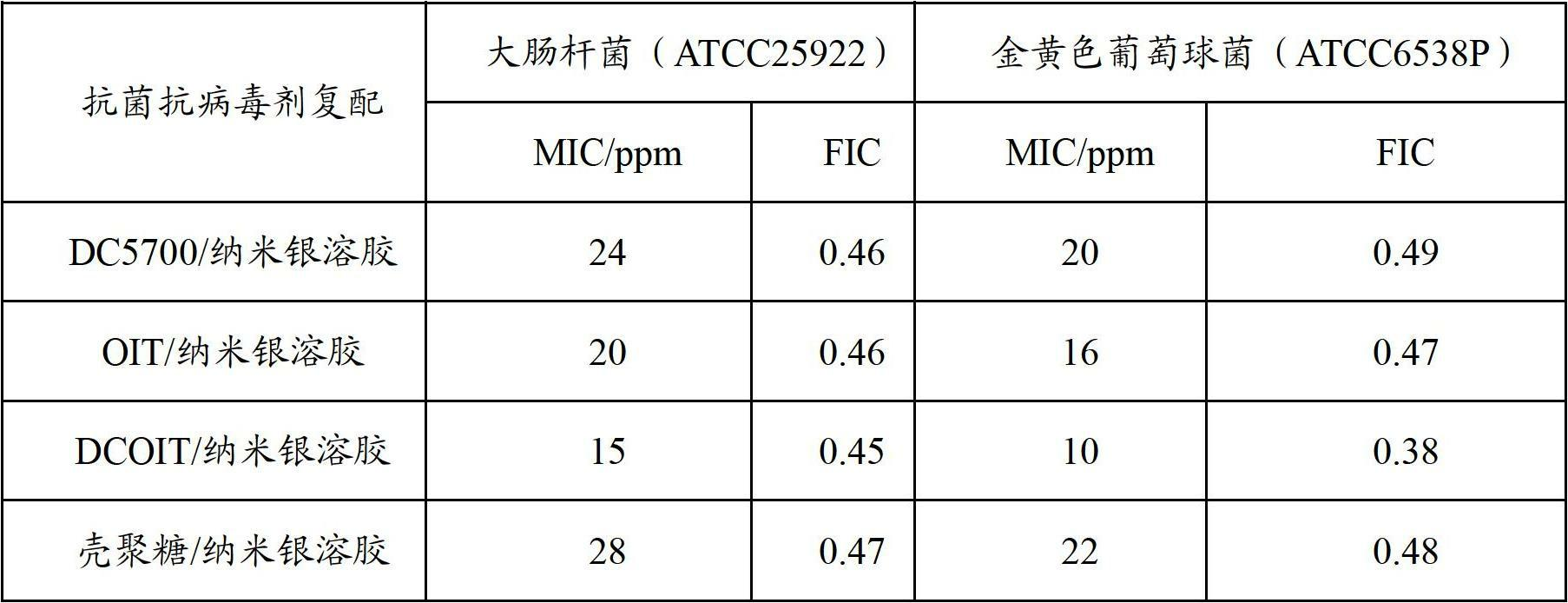

Examples

Embodiment 1

[0152] Embodiment 1: the preparation of antibacterial and antiviral treatment agent of the present invention

[0153] Its preparation steps are as follows:

[0154] Step A: Add 5 parts by weight of DC5700 produced by Dow Corning Corporation of the United States and 8 parts by weight of co-solvent ethanol to the batching tank produced by Beijing Jingxin Tongmao Machinery Equipment Co., Ltd., and stir for 20 minutes at a temperature of 60 ° C and a speed of 800 rpm , so that DC5700 is completely dissolved in ethanol to obtain a uniform and transparent solution; then add 59 parts by weight of water to this solution, and continue to stir for 20-30min to make it a uniform and transparent solution.

[0155] Step B: Add 20 parts by weight of acrylate emulsion produced by Beijing Huyi Chemical Factory to the uniform transparent solution obtained in Step A from the feed port at the upper end of the batching tank, stir for 30 minutes at a temperature of 40°C and a speed of 1200 rpm, and...

Embodiment 2

[0158] Embodiment 2: the preparation of antibacterial and antiviral treatment agent of the present invention

[0159] Its preparation steps are as follows:

[0160] Step A: Add 8 parts by weight of OIT produced by Beijing Tianqing Chemical Co., Ltd. and 10 parts by weight of cosolvent propylene glycol to the batching tank produced by Beijing Jingxin Tongmao Machinery Equipment Co., Ltd., under the conditions of temperature 70 ° C and 1000 rpm Stir for 20 minutes to completely dissolve OIT in propylene glycol to obtain a uniform and transparent solution; then add 42 parts by weight of water to this solution and continue stirring for 20-30 minutes to make it a uniform and transparent solution.

[0161] Step B: Add 30 parts by weight of polyurethane emulsion produced by Beijing Umitech Co., Ltd. to the uniform transparent solution obtained in step A from the feed port at the upper end of the batching tank, stir for 60 minutes at a temperature of 50°C and a speed of 1200 rpm, and ...

Embodiment 3

[0164] Embodiment 3: the preparation of antibacterial and antiviral treatment agent of the present invention

[0165] Its preparation steps are as follows:

[0166] Step A: Add a mixture of 2 parts by weight of DCOIT produced by Dalian Baiao Chemical Co., Ltd. and 12 parts by weight of co-solvent ethanol / glycerol (weight ratio 2:1) to the batching tank produced by Beijing Jingxin Tongmao Machinery Equipment Co., Ltd. In the process, stir for 20min at a temperature of 70°C and a rotation speed of 1000rpm, so that DCOIT is completely dissolved in the ethanol / glycerol mixture to obtain a uniform and transparent solution; then add 65 parts by weight of water to this solution and continue stirring 20-30min to make it a uniform and transparent solution.

[0167] Step B: Add 20 parts by weight of polyurethane emulsion produced by Beijing Umitech Co., Ltd. to the uniform transparent solution obtained in step A from the feed port at the upper end of the batching tank, stir for 30 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com