Preparation method for heat resisting milk essence and application of obtained product

A technology with milk flavor and high temperature resistance, which is applied in the field of food additives to achieve the effect of simple operation process, comfortable taste and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

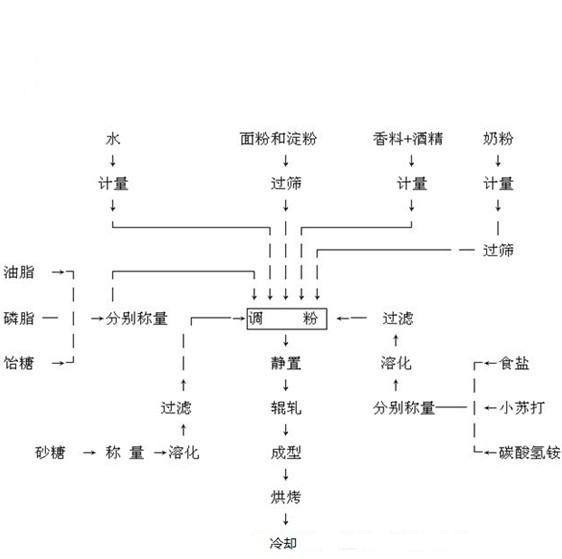

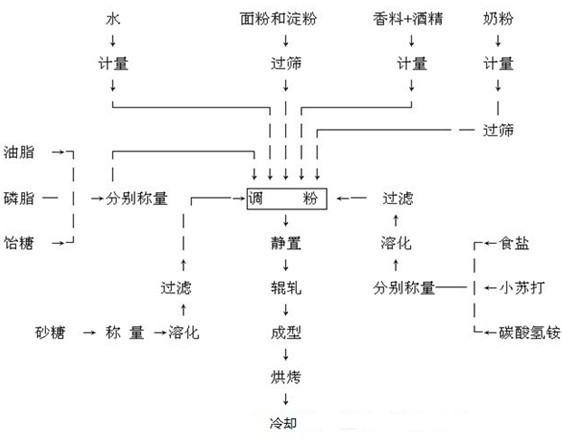

Image

Examples

Embodiment 1

[0022] Preparation of a blended high-temperature resistant milk flavor essence,

[0023] serial number raw material name Dosage / serving 1 ethyl acetate 0.003 2 diacetyl 0.200 3 Butyryl Lactate 0.120 4 Acetoin 0.050 5 butyric acid 0.200 6 Benzaldehyde 0.080 7 Furanone 0.100 8 2-nonanone 0.015 9 Nonalactone 0.200 10 Butydecalactone 0.150 11 capric acid 0.080 12 Vanillin 0.300 13 Ethyl vanillin 0.130 14 Gamma undecalactone 0.180 15 ethyl maltol 0.150 16 butyl laurolactone 0.280 17 tetradecanoic acid 0.200 18 Vanillin Propylene Glycol Acetal 0.280 19 salad oil 97.282 20 total 100.000

[0024] In the milk flavor prepared according to the above ratio, the mass ratio of the low-boiling point flavor (boiling point<250°C) to the high-boiling point flavor (boiling point≥250°C) is about 30%.

[0025] An application of the above-menti...

Embodiment 2

[0027] Preparation of another blended high temperature resistant milk flavor essence,

[0028] serial number raw material name Dosage / serving 1 diacetyl 0.240 2 Acetic acid 0.006 3 ethyl butyrate 0.300 4 2-Heptanone 0.036 5 Benzaldehyde 0.090 6 2-nonanone 0.018 7 Dodecanoic acid 0.650 8 gamma caprolactone 0.036 9 Gamma laurolactone 0.120 10 Butydecalactone 0.200 11 Thioacetate 0.080 12 ethyl dodecanoate 0.018 13 Gamma Decalactone 0.018 14 Vanillin 0.960 15 Ethyl vanillin 0.200 16 ethyl maltol 0.180 17 butyl laurolactone 0.420 18 tetradecanoic acid 0.240 19 salad oil 96.188 20 total 100.000

[0029] In the milk flavor prepared according to the above ratio, the mass ratio of the low-boiling point flavor (boiling point<250°C) to the high-boiling point flavor (boiling point≥250°C) is about 30%.

[0030] An application of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com