Method of comprehensively recycling food waste

A food waste and solid technology, which is applied in the field of comprehensive recycling of food waste, can solve the problems of technical requirements and high energy consumption costs, effective treatment of impurities, and raw materials containing many impurities, etc., achieve significant economic and social benefits, and eliminate gutters The effect of oil production and simple structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

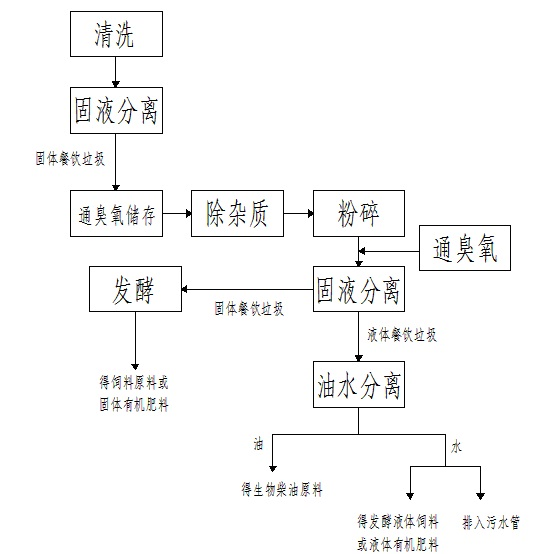

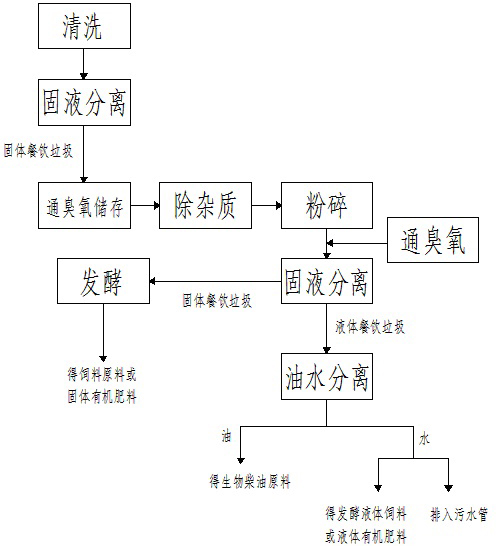

[0041] like figure 1 Shown, the method for the comprehensive recycling of catering waste of the present invention, the steps are as follows:

[0042] A. Put the food waste into the cleaning pool of 40-60 degrees hot water for 2 minutes, and carry out solid-liquid separation treatment;

[0043] B. Store the solid catering waste after solid-liquid separation treatment through ozone disinfection, sterilization, deodorization and fresh-keeping treatment;

[0044] C. Put the food waste into the magnetic impurity sedimentation tank, add 40-60 ℃ hot water, stir for 2-5 minutes, and precipitate the impurities;

[0045] D. After cleaning, the food waste is crushed into particles with a diameter of less than 3mm, and the food waste is separated from the solid and liquid while the ozone is used for disinfection, sterilization, deodorization and freshness preservation;

[0046] E. Feed raw materials or solid organic fertilizers are obtained after fermenting the separated solid caterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com