Ultrahigh pressure water jet velocity optimal control method extracted based on voice characteristics

A sound feature and optimized control technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems of low efficiency, difficult to meet the requirements of flexible manufacturing high smoothness adaptive control, etc., to reduce labor intensity , strong practicability, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

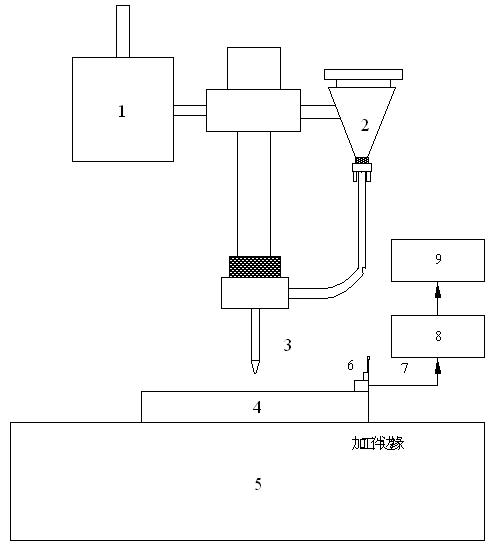

[0016] see figure 1 , first set up the sound signal computer acquisition and control system on the existing ultra-high pressure water jet cutting machine, the existing ultra-high pressure water jet cutting machine includes booster pump system 1, sand adding part 2 and water jet nozzle 3, processing workpiece 4 Fixed on the workbench 5, the sound signal computer acquisition and control system is composed of a sound sensor 6, a sound signal transmission line 7, a signal amplification conditioning module 8 and a computer system 9 connected in series in sequence, wherein the sound sensor 6 is arranged on the workpiece 4, Multiple acoustic sensors 6 can be used with the present invention.

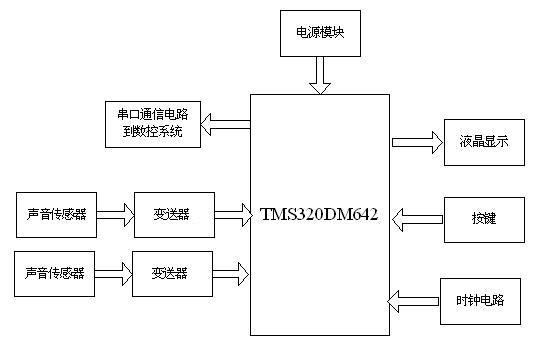

[0017] see figure 2 , the computer system 9 is based on TMS320DM642 DSP as the core sound acquisition computer system, the signal amplification and conditioning module 8 adopts the AWA14604 type preamplifier to form the front-end test unit, and sends it to the computer I / O interface through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com