Deep oxidation method and deep oxidation device in the production of polymer grade terephthalic acid

A terephthalic acid and deep oxidation technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as unreasonable energy utilization, complex impurity removal system, and no factory establishment, etc., to achieve the reaction process And the reaction conditions are reasonable, the process parameters are set reasonably, and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

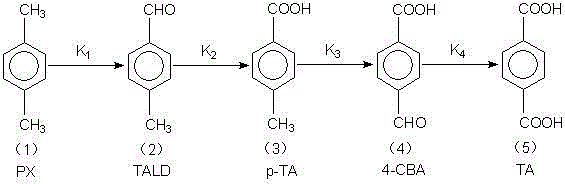

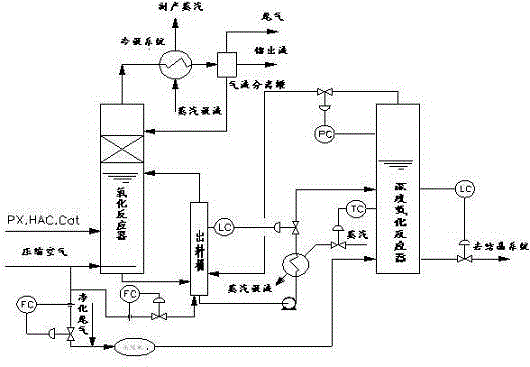

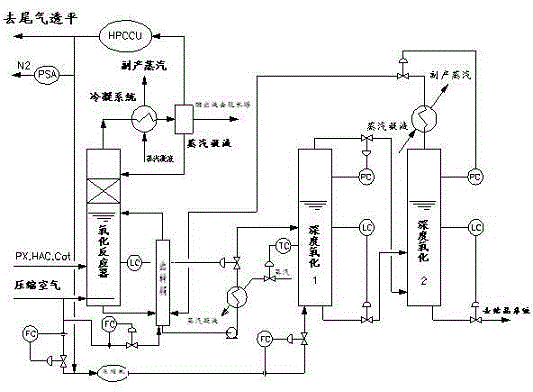

[0029] see Figure 1-3 , In the deep oxidation device provided by the present invention, the tower reactor without stirring is used, which saves the electricity for stirring, simplifies the equipment, and greatly reduces the investment.

[0030] The present invention relates to the process that generates TA by the oxidation of PX, goes through many intermediate chemical reactions, and its main reaction process is as seen figure 1 As shown, the activation energy of each intermediate reaction is as follows:

[0031] K1——PX oxidation to generate TALD (p-tolualdehyde), activation energy 65kJ / mol

[0032] K2——TALD oxidation to PT acid (p-toluic acid), activation energy 51.5kJ / mol

[0033] K3——PT acid oxidation to generate 4-CBA (p-carboxybenzaldehyde), activation energy 85.1kJ / mol

[0034] K4——4-CBA is oxidized to TA (terephthalic acid), the activation energy is 78.3kJ / mol

[0035] In terms of the difficulty of the reaction, the first and second steps are the fastest, the third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com