Preparation method of high-molecular-weight squid skin collagen

A technology of high molecular weight and skin collagen, which is applied in the field of protein materials in biotechnology, can solve the problems of the molecular weight gap of squid skin collagen and the low utilization level of squid skin collagen, and achieve good mechanical properties, low cost and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

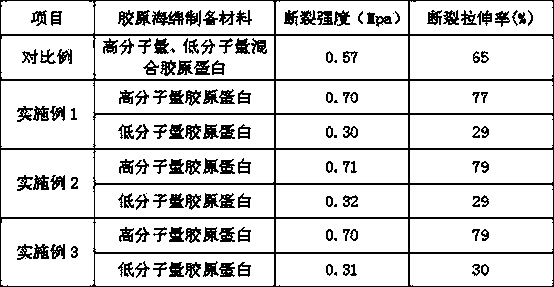

Embodiment 1

[0035]Take 0.4 Kg of squid skin, wash it with clean water after thawing and mash it, add 30 ml of 0.1mol / L NaOH solution to each gram of squid skin, add 12L NaOH solution, soak at 4°C for 24 hours, then add 30 ml per gram of squid skin Add 12L of n-butanol solution to 10% n-butanol solution by volume, stir for 16 hours, and drain. Add 10ml of distilled water to each gram of squid skin and add 4L of distilled water to the squid skin. 0.4g of Bacillus subtilis neutral protease at 0.1% by weight, hydrolyze at 4°C for 6 h, then adjust the pH to 1 with hydrochloric acid, add 1.2g of pepsin at 0.3% by weight of squid skin, and continue to enzymolyze at 4°C After 16 hours, select an ultrafiltration membrane with a molecular cut-off of 100kd to carry out centrifugal ultrafiltration on the enzymolysis solution, adjust the pH of the filtrate to 4 with ammonia water, and then add ammonium sulfate to the filtrate until the concentration is 2 mol / L, so that the squid skin Collagen is salte...

Embodiment 2

[0037] Take 0.4Kg squid skin, wash it with clean water after thawing and mash it, add 40 ml 0.3 mol / L NaOH solution to each gram of squid skin, add 16 L NaOH solution, soak at 5°C for 28 hours, then add 40 ml per gram of squid skin Add 16L of n-butanol solution to 10% n-butanol solution in ml volume percent, stir for 18 h and drain, add 15 ml of distilled water per gram of squid skin to add 6 L of distilled water to the dried squid skin, add as 0.8g of Bacillus subtilisin neutral protease with 0.2% weight of squid skin, enzymatic hydrolysis at 7°C for 8 hours, then adjust the pH to 1.2 with hydrochloric acid, then add 1.6g of pepsin with 0.4% weight of squid skin, continue at 7°C After 18 hours of enzymolysis, the enzymolyzed solution was centrifuged and ultrafiltered with an ultrafiltration membrane with a molecular cut-off of 100kd, and the pH of the filtrate was adjusted to 3 with ammonia water, and then sodium phosphate was added to the filtrate until the concentration was ...

Embodiment 3

[0039] Take 0.4 Kg squid skin, wash it with clean water after thawing and mash it, add 50 ml of 0.5 mol / L NaOH solution per gram of squid skin, add 20 L NaOH solution, soak at 10°C for 30 h, and then add per gram of squid skin Add 20 L of n-butanol solution to 50 ml of 10% n-butanol solution by volume, stir for 24 h and drain, add 20 ml of distilled water per gram of squid skin to the drained squid skin, add 8 L of distilled water, Add 1.2 g of Bacillus subtilisin neutral protease with 0.3% weight of squid skin, enzymatically hydrolyze at 10°C for 10 h, adjust the pH to 1.5 with hydrochloric acid, add 2.0 g of pepsin with 0.5% weight of squid skin, and continue at 10°C Enzymolysis was performed for 20 h, and the enzymolysis solution was centrifugally ultrafiltered with an ultrafiltration membrane with a molecular cut-off of 100 kd. The pH of the filtrate was adjusted to 5 with ammonia water, and then sodium chloride was added to the filtrate until the concentration was 2.5 mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com