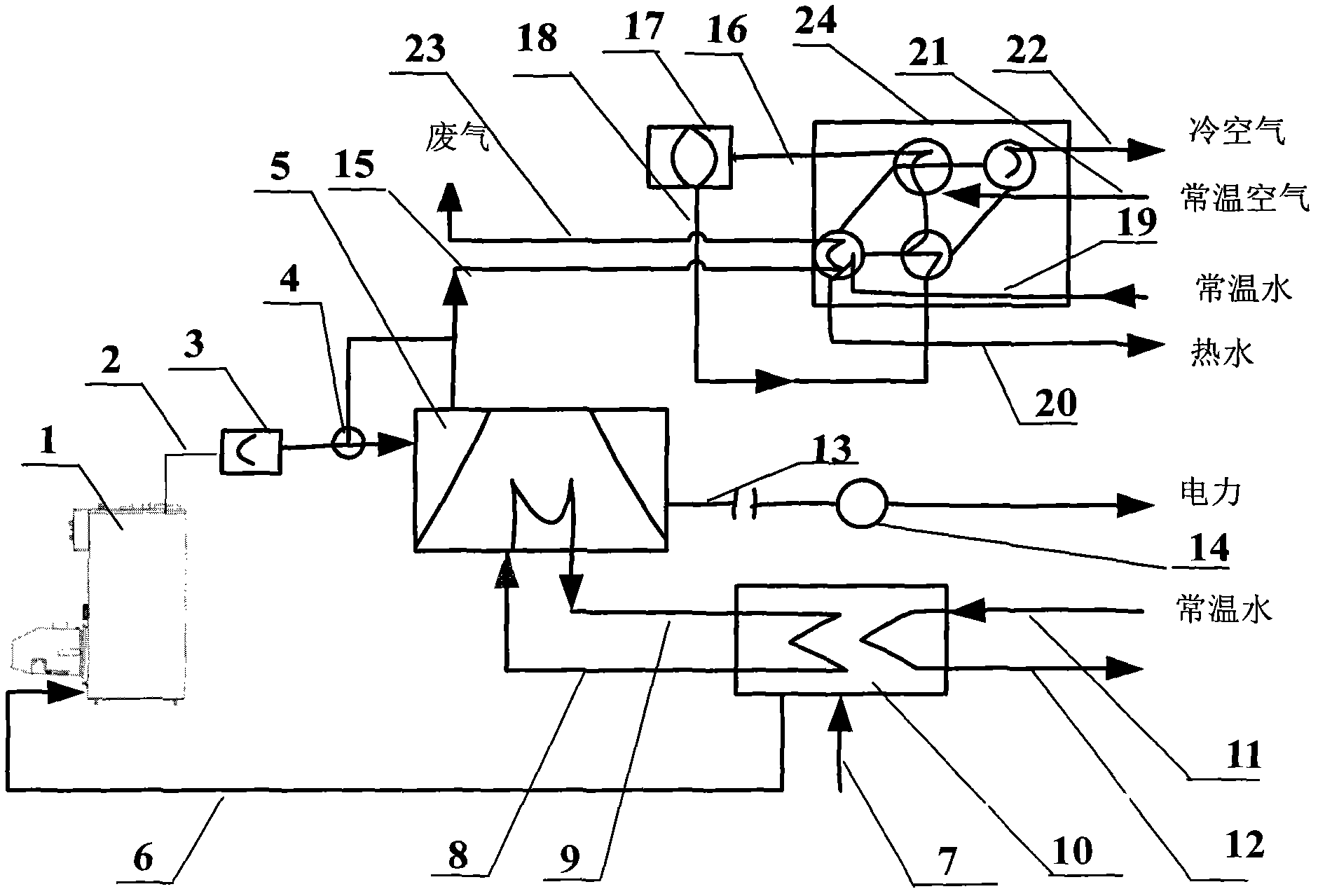

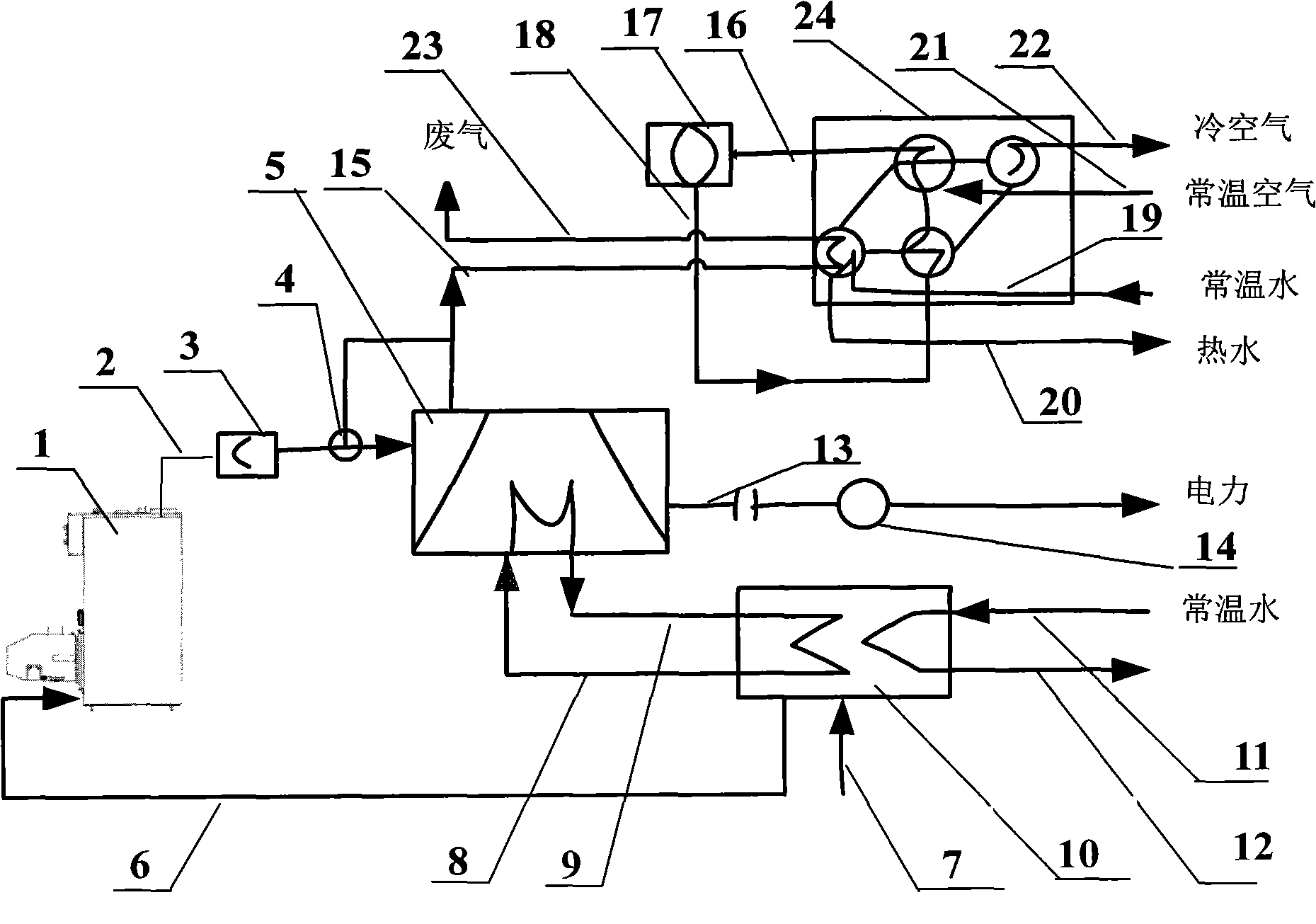

Biomass distributed combined cooling heating and power energy system

A technology for co-production of energy and biomass, applied to lighting and heating equipment, machines using waste heat, and machine operation methods to achieve the effects of improving combustion efficiency, energy utilization efficiency, and utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Example: Biomass distributed cooling, heating and power polygeneration energy system for a primary and secondary school in the suburbs of Beijing

[0031] According to the present invention, a biomass distributed cooling, heating and power polygeneration energy system is established in a primary and secondary school in the suburbs of Beijing, with a total construction area of 6000 square meters. Before the biomass distributed cooling, heating, power polygeneration energy system was established, the There is a 700kw biomass boiler with an annual consumption of 2,500 tons of briquette fuel, a heating time of 120 days, and an energy utilization rate of only 80%. After adopting the present invention to construct a biomass distributed cooling, heating, and electricity polygeneration energy system, the annual consumption of straw is 6,000 tons. In addition to heating in winter, it is used for room cooling in summer, replacing air conditioners, and generating electricity at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com