Method for preparing graphene gas sensors in batches based on nano soft lithography

A gas sensor, graphene technology, applied in instruments, measuring devices, scientific instruments, etc., can solve the problems of inconsistent performance of graphene sensors, difficult to control the shape and size of graphene, and unfavorable integration of micro-nano-scale graphene sensors. Conducive to integration, improved sensitivity, and consistent shape rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0040] Specific Embodiment 1: This embodiment provides a new method for preparing graphene gas sensors in batches based on nano soft printing technology, which is specifically completed according to the following steps:

[0041] 1. Preparation of graphene film:

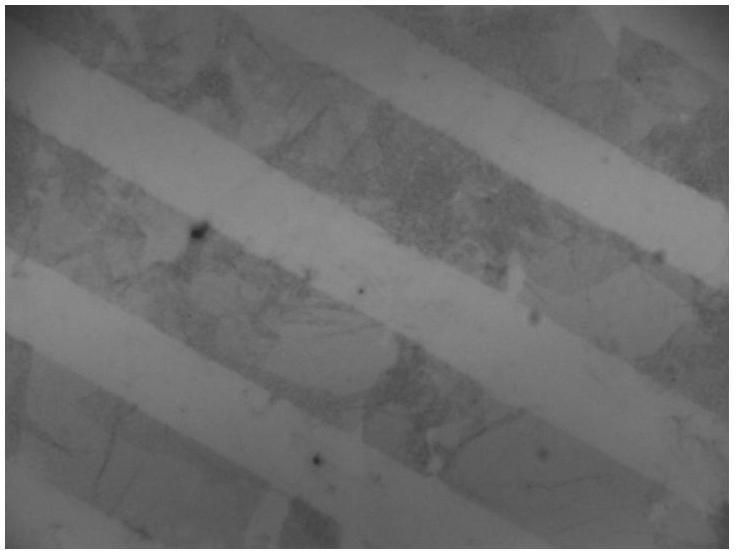

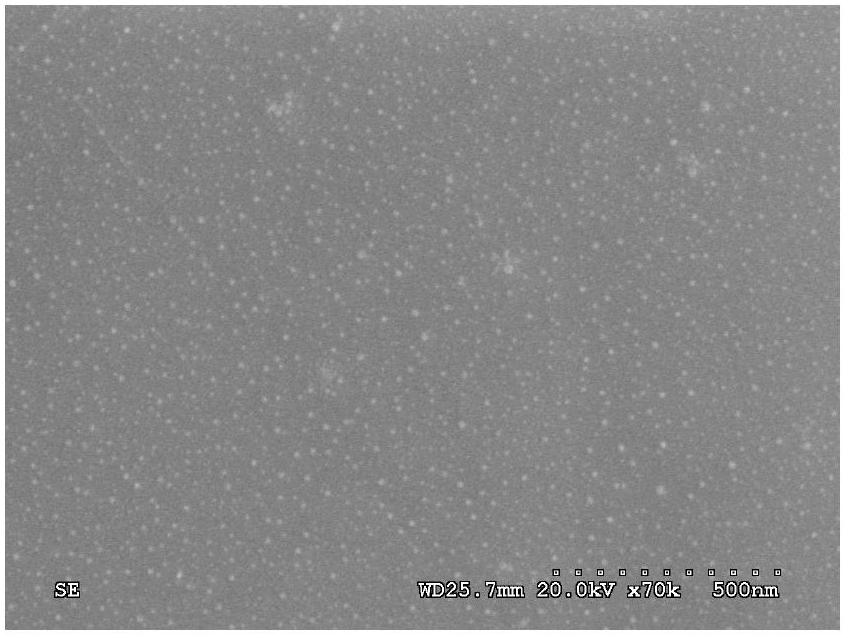

[0042] (1) Preparation of graphene oxide film: make graphene oxide into a suspension with a concentration of 0.0001~0.0005g / ml, and then drop a layer of graphene oxide suspension on the cleaned silicon wafer with a 300nm thick oxide film solution, and dry the silicon wafer at a temperature of 30-90°C for 10min-1h.

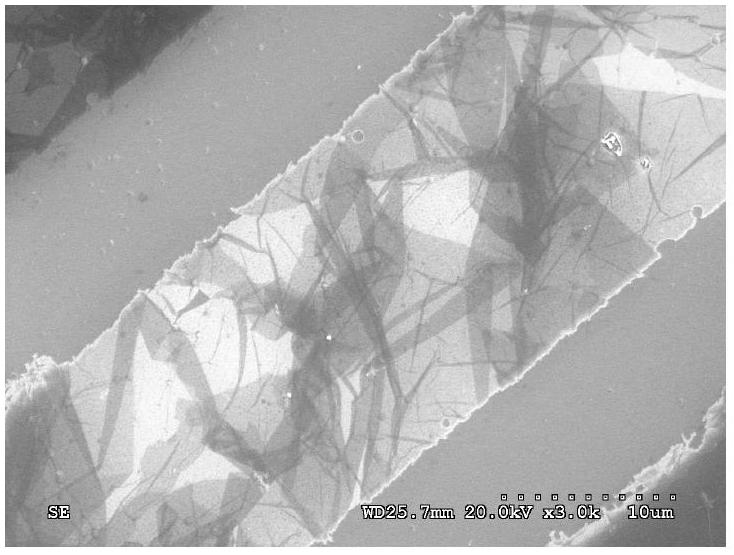

[0043] (2) Preparation of CVD graphene film: CVD graphene prepared with copper foil as catalyst was transferred to silicon wafer with oxide layer.

[0044] 2. Preparation of regular-shaped graphene:

[0045] ①. After the graphene oxide on the silicon wafer is dried in step 1, spin coat a layer of polymethyl methacrylate on its surface, and the spin coating speed is 2000r / min~12000r / min.

[0046] ②. Place ...

specific Embodiment approach 2

[0058] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the graphene oxide described in step 1 (1) is made into a suspension with a concentration of 0.0002-0.0004 g / ml. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0059] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the graphene oxide described in step 1 (1) is made into a suspension with a concentration of 0.0003 g / ml. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com