High-entropy brazing filler metal for brazing non-oxide ceramics and non-oxide ceramic composite material and preparation method of brazing filler metal

A non-oxide and composite material technology, applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., can solve the problems of unreliable performance of high-temperature solder, and achieve improved compatibility, low cost, and suitable melting point Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

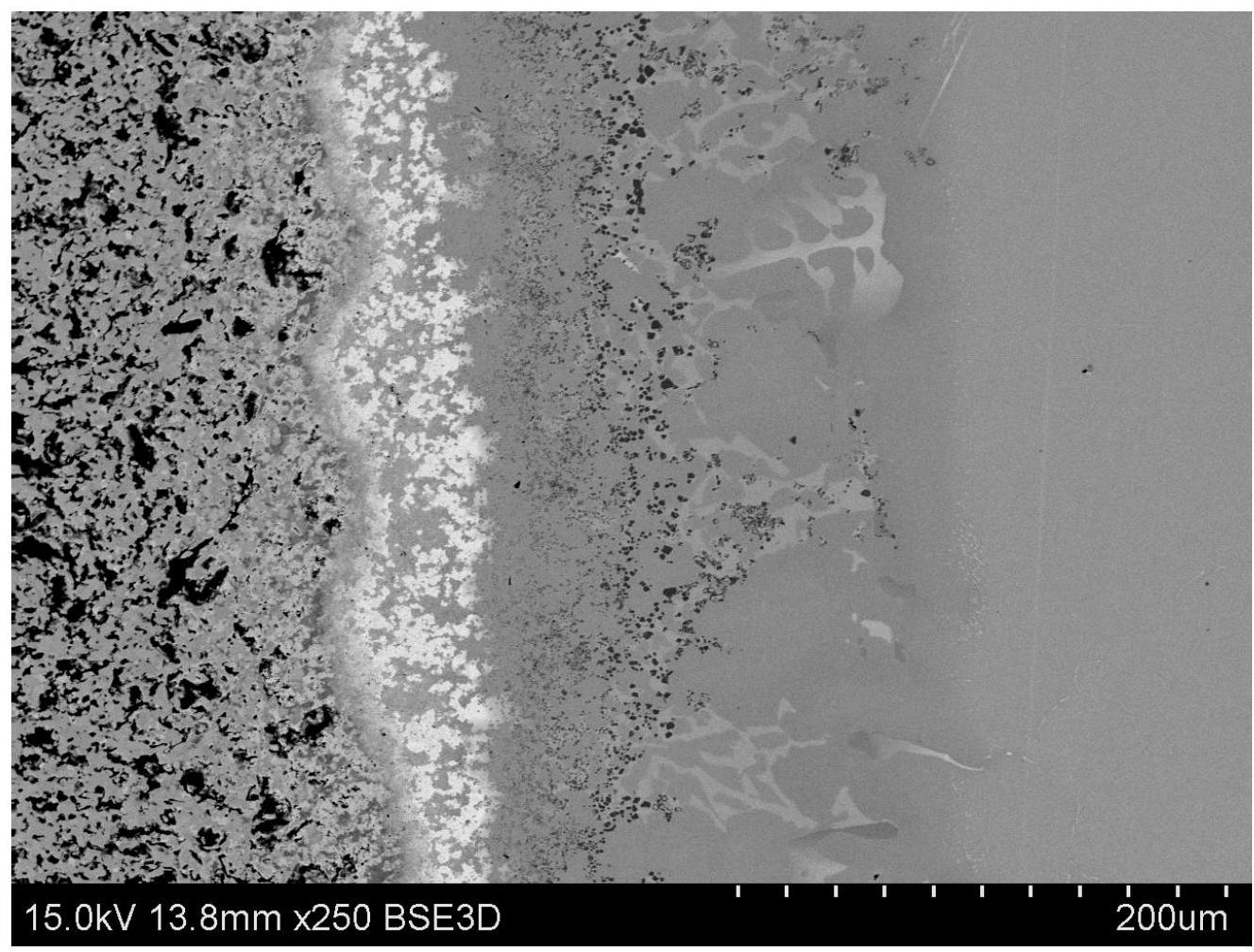

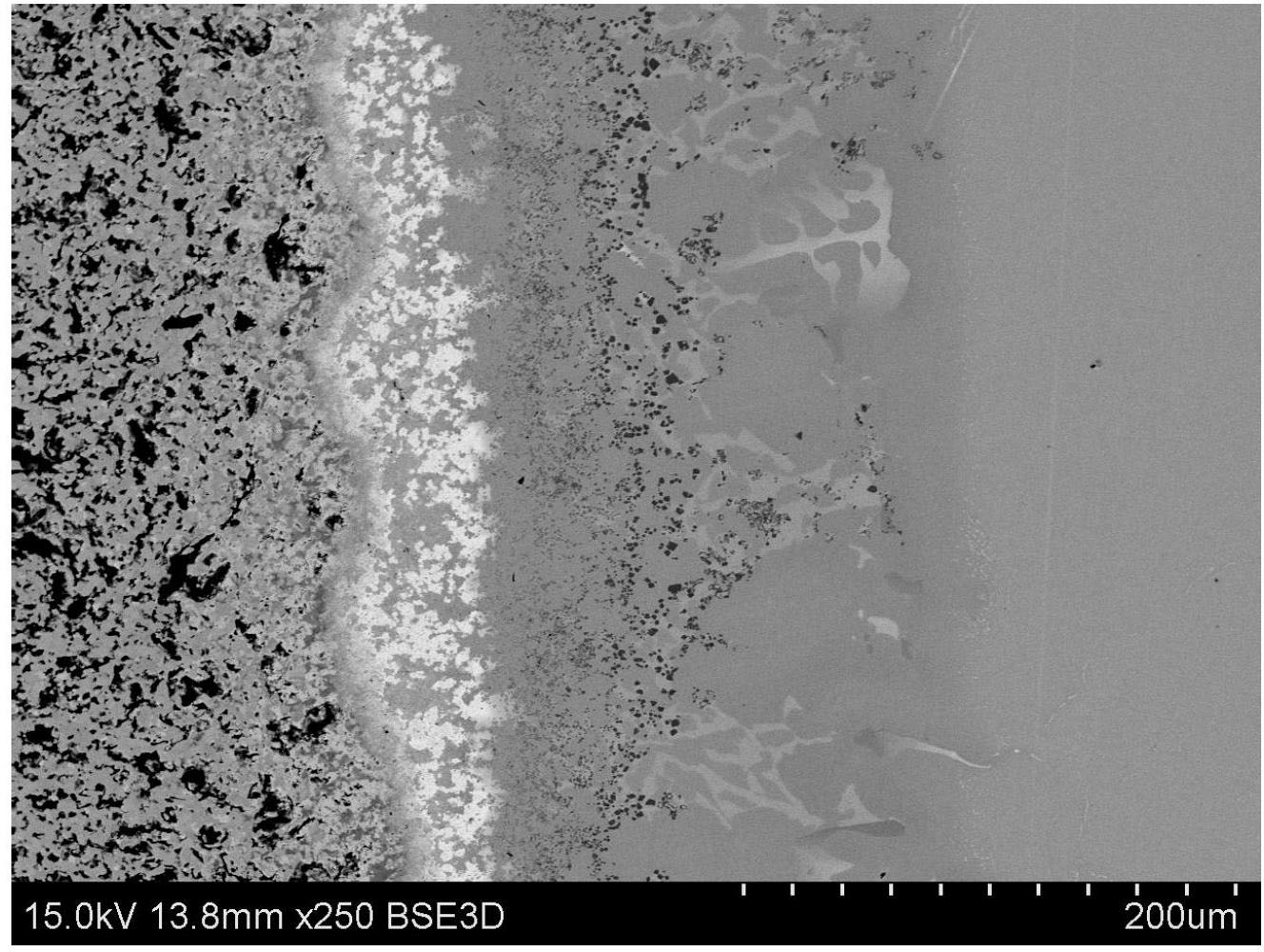

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode one: a kind of high-entropy solder for brazing non-oxide ceramics and its composite materials in this embodiment is composed of 18-24 parts by weight of Ni, 14.3-19 parts of Cr, 16.8-22.5 parts Parts of Co, 15.9~21 parts of Fe, 10.1~13.5 parts of Cu and 0~24.9 parts of Ti or TiH 2 composition.

[0016] This embodiment realizes direct brazing of non-oxide ceramics and their composite materials themselves or with metals, without any modification treatment on the surface of ceramics or composite materials before welding. The high-entropy solder of this embodiment has a suitable melting point and good wettability for brazing non-oxide ceramics and their composite materials and various high-temperature alloys, and can meet the requirements for brazing joints at 800°C. Moreover, the brazing filler metal of this embodiment does not contain precious metals such as Ag and Pd, and the cost is low. When the high-entropy solder used in this embodiment...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the purity of Ni is 99.0%~99.9%, the purity of Cr is 99.0%~99.9%, the purity of Co is 99.0%~99.9%, and the purity of Fe is 99.0%~99.9%. 99.0%~99.9%, Cu purity 99.0%~99.9% and Ti purity 99.0%~99.9% or TiH 2 It is 99.0%~99.9%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is different from Embodiments 1 to 2 in that Ni, Cr, Co, Fe, Cu and Ti are metal powders or foils. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com