Skin wound repair hydrogel and preparation method thereof

A technology for skin wounds and repairing water, applied in medical science, bandages, absorbent pads, etc., can solve the problems of degradation products that easily cause inflammation, poor hygroscopicity and water permeability, and large-area skin lesions are not suitable, so as to benefit Effects of tissue growth, softening of skin, and pain relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

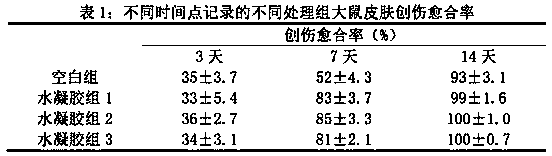

Examples

Embodiment 1

[0023] 1. Extraction of Aloe Vera Gum

[0024] Choose 10-year-old fresh aloe vera, wash it with tap water, wash it twice with distilled water, put it in a sterile operating table, and sterilize it with ultraviolet radiation for 30 minutes. After the sterilization is completed, use a scalpel to peel off the leaves to get the pulp. After the pulp is crushed with a juicer, put it into a 50mL centrifuge tube, centrifuge at 15000 rpm for 5min, and separate the supernatant, which is sterile aloe raw gum.

[0025] 2. Preparation of chitosan solution

[0026] Add 4g of chitosan into 100mL of 3% (v / v) acetic acid solution, stir and dissolve at 40°C to obtain a 4% (w / v) chitosan solution. Take 50mL chitosan solution and put it into a 3000kDa dialysis membrane, dialyze in 2L distilled water at 4°C for 6 days, and change the water every other day. Then the chitosan solution diluted by dialysis is placed in a beaker, placed in an oven at 50° C. to evaporate water and concentrate to 50 m...

Embodiment 2

[0033] 1. Extraction of Aloe Vera Gum

[0034] Choose 10-year-old fresh aloe vera, wash it with tap water, wash it twice with distilled water, put it in a sterile operating table, and sterilize it with ultraviolet radiation for 30 minutes. After the sterilization is completed, use a scalpel to peel off the leaves to get the pulp. After the pulp is crushed with a juicer, put it into a 50mL centrifuge tube, centrifuge at 15000 rpm for 5min, and separate the supernatant, which is sterile aloe raw gum.

[0035] 2. Preparation of chitosan solution

[0036] Add 4g of chitosan into 100mL of 3% (v / v) acetic acid solution, stir and dissolve at 40°C to obtain a 4% (w / v) chitosan solution. Take 50mL chitosan solution and put it into a 3000kDa dialysis membrane, dialyze in 2L distilled water at 4°C for 6 days, and change the water every other day. Then the chitosan solution diluted by dialysis is placed in a beaker, placed in an oven at 50° C. to evaporate water and concentrate to 50 m...

Embodiment 3

[0043] Choose 6-year-old fresh aloe vera, wash it with tap water, wash it twice with distilled water, then place it in a sterile operating table, and sterilize it with ultraviolet radiation for 30 minutes. After the sterilization is completed, use a scalpel to peel off the leaves to get the pulp. After the pulp is crushed with a juicer, put it into a 50mL centrifuge tube, centrifuge at 15000 rpm for 5min, and separate the supernatant, which is sterile aloe raw gum.

[0044] 2. Preparation of chitosan solution

[0045] Add 4g of chitosan into 100mL of 3% (v / v) acetic acid solution, stir and dissolve at 40°C to obtain a 4% (w / v) chitosan solution. Take 50mL chitosan solution and put it into a 3000kDa dialysis membrane, dialyze in 2L distilled water at 4°C for 6 days, and change the water every other day. Then the chitosan solution diluted by dialysis is placed in a beaker, placed in an oven at 60° C. to evaporate water and concentrate to 50 mL, and the pH value of the chitosan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com