Combined self-control membrane bioreactor and method for treating low-temperature low-turbidity high-chroma high-ammonia nitrogen source water using same

A membrane bioreactor and composite technology, which is applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost and low processing capacity, so as to reduce the treatment cost and improve the applicability Strong, reduce the effect of equipment wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

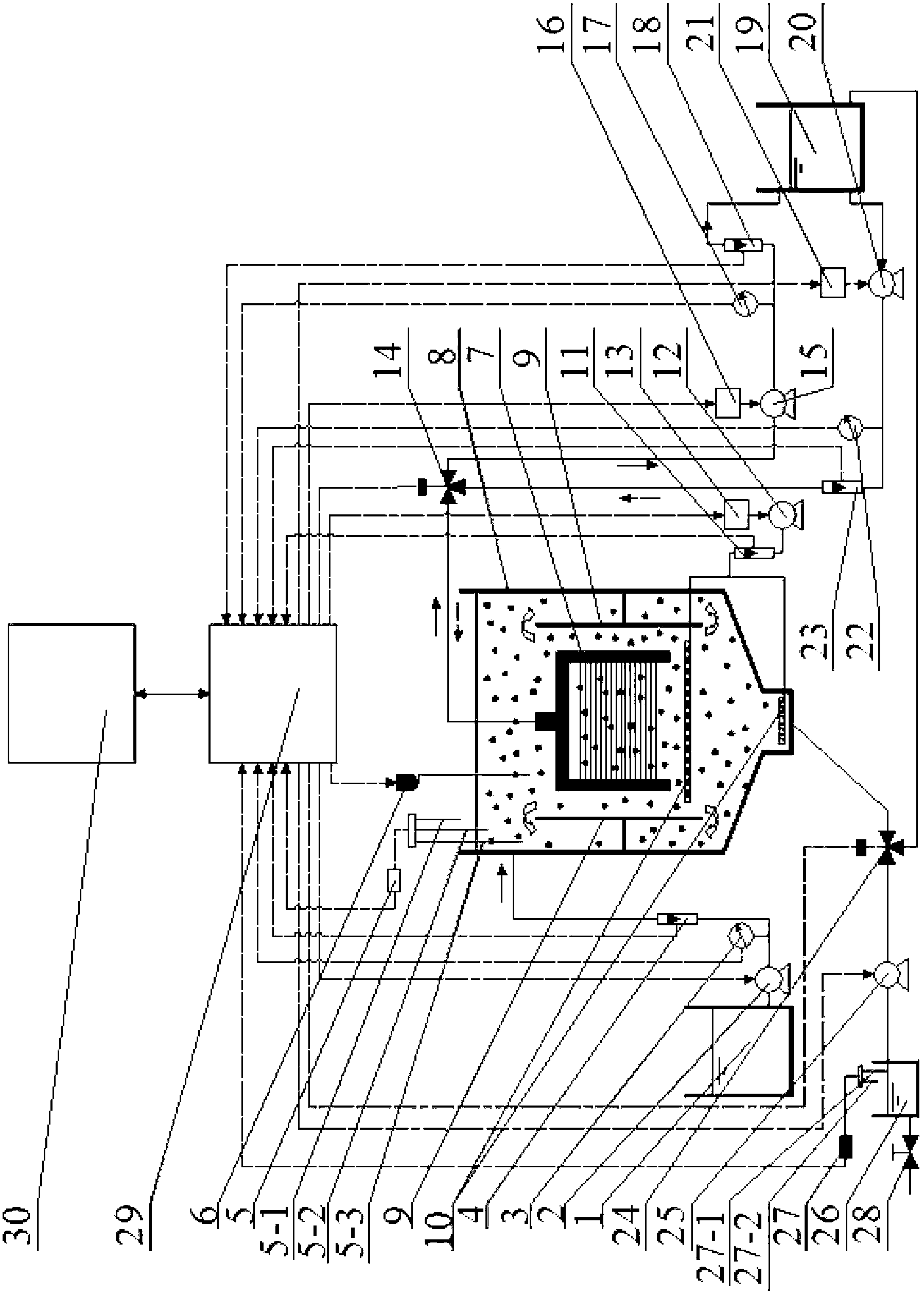

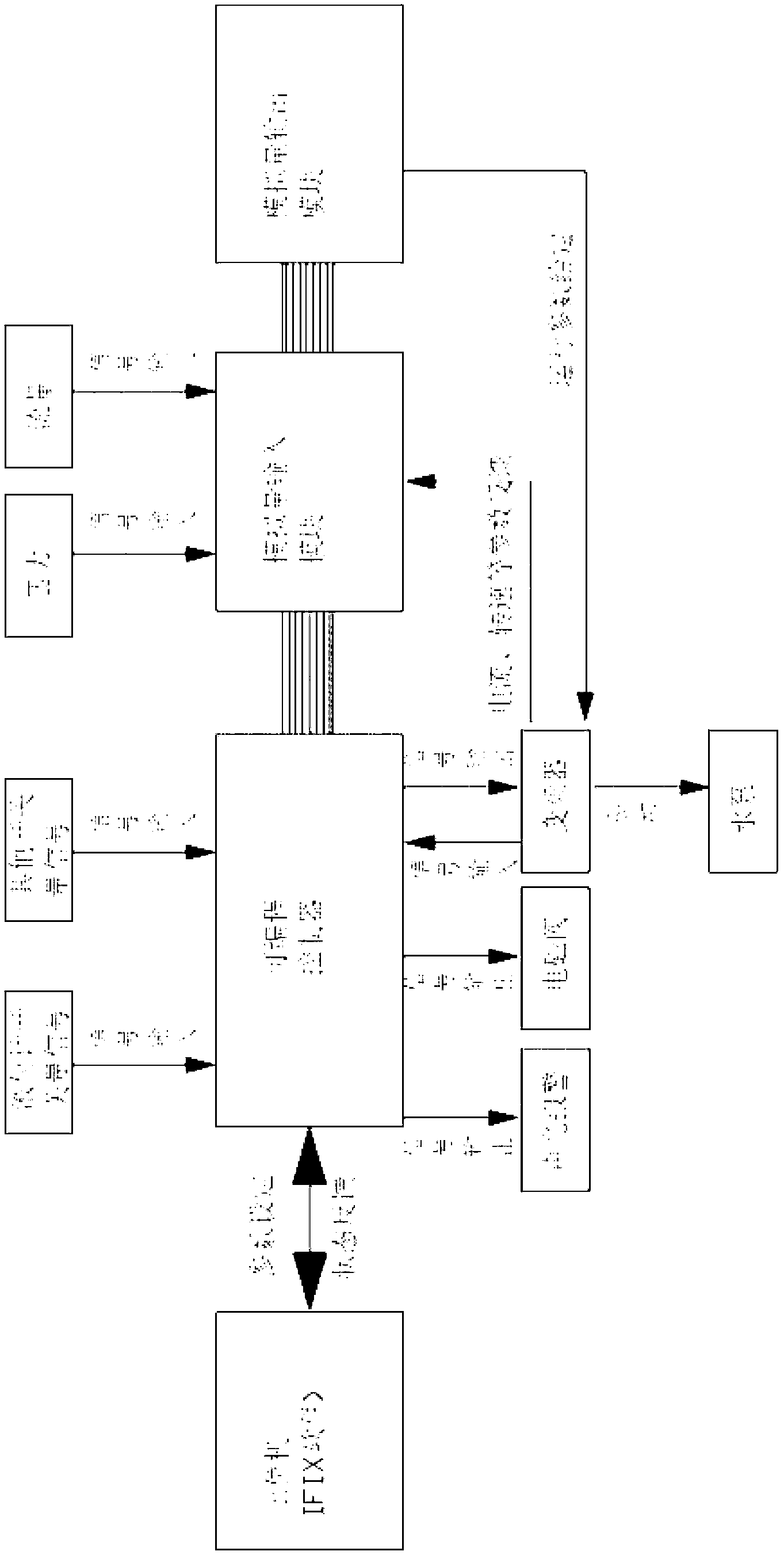

[0011]Specific embodiment 1: This embodiment is a composite self-control membrane bioreactor consisting of a water distribution tank 1, an inlet pump 2, an inlet pressure gauge 3, an inlet flowmeter 4, an inlet level sensor 5, a dosing device 6, Membrane module 7, membrane bioreactor 8, guide tube 9, aeration pipe 10, gas flow meter 11, air pump 12, first frequency converter 13, outlet water-backwash three-way solenoid valve 14, outlet water constant flow suction Pump 15, second inverter 16, outlet water pressure gauge 17, outlet water flowmeter 18, clean water tank 19, backwash pump 20, third inverter 21, backwash pressure gauge 22, backwash flowmeter 23, mud discharge tee Solenoid valve 24, mud pump 25, mud storage tank 26, mud level sensor 27, mud valve 28, programmable logic controller (PLC) 29 and upper computer (IFIX software) 30, in which the water distribution tank 1 , water inlet pump 2, water inlet pressure gauge 3, water inlet flowmeter 4 and water inlet liquid leve...

specific Embodiment approach 2

[0017] Specific implementation mode 2: This implementation mode is a method for treating low-temperature, low-turbidity, high-color, high-ammonia-nitrogen source water with a composite self-controlling membrane bioreactor. First, low-temperature, low-turbidity, high-color, high-ammonia-nitrogen source water is added to the water distribution tank 1 and the membrane bioreactor 8, and the liquid level of the sewage to be treated in the membrane bioreactor 8 is at the probe end of the upper limit water level probe 5-1 and the lower limit water level probe 5 Between -2 probe ends, the water inlet liquid level sensor 5 feeds back the signal to the programmable logic controller (PLC) 29, at this time the programmable logic controller (PLC) 29 controls the dosing device 6 to start, and the modified palygorskite The flocculation adsorbent is put into the membrane bioreactor 8, and the dosage is 30g / L~40g / L. At the same time, the programmable logic controller (PLC) 29 starts the air pum...

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the modified palygorskite flocculation adsorbent described in step one is specifically prepared according to the following steps: 1. Purification: firstly, the natural palygorskite is decomposed with Add the natural palygorskite into the deionized water according to the mass ratio of 1: (18~99), and then stir and disperse it at a stirring speed of 1000r / min~10000r / min for 10min~30min to obtain a clay slurry, and then mix the clay The slurry is placed in a centrifuge, and centrifuged at a centrifugal speed of 4000r / min~12000r / min for 10min~20min. After separation, an off-white clay paste is obtained, and dried at a temperature of 80°C~120°C to constant weight, and then After being crushed through a 200 mesh sieve, the purified palygorskite with a particle size of below 200 mesh is obtained; 2. Loading: firstly, chitosan with a deacetylation degree of 85% to 95% is dissolved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com