Method for processing starch waste water and realizing resourcezation of waste water by one photosynthetic bacterium strain

A technology for treating starch and photosynthetic bacteria, which is applied in chemical instruments and methods, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of low sewage treatment efficiency, low degree of resource utilization, complex process flow, etc., to achieve The effect of recycling sewage, simplifying the process flow, and overcoming serious secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

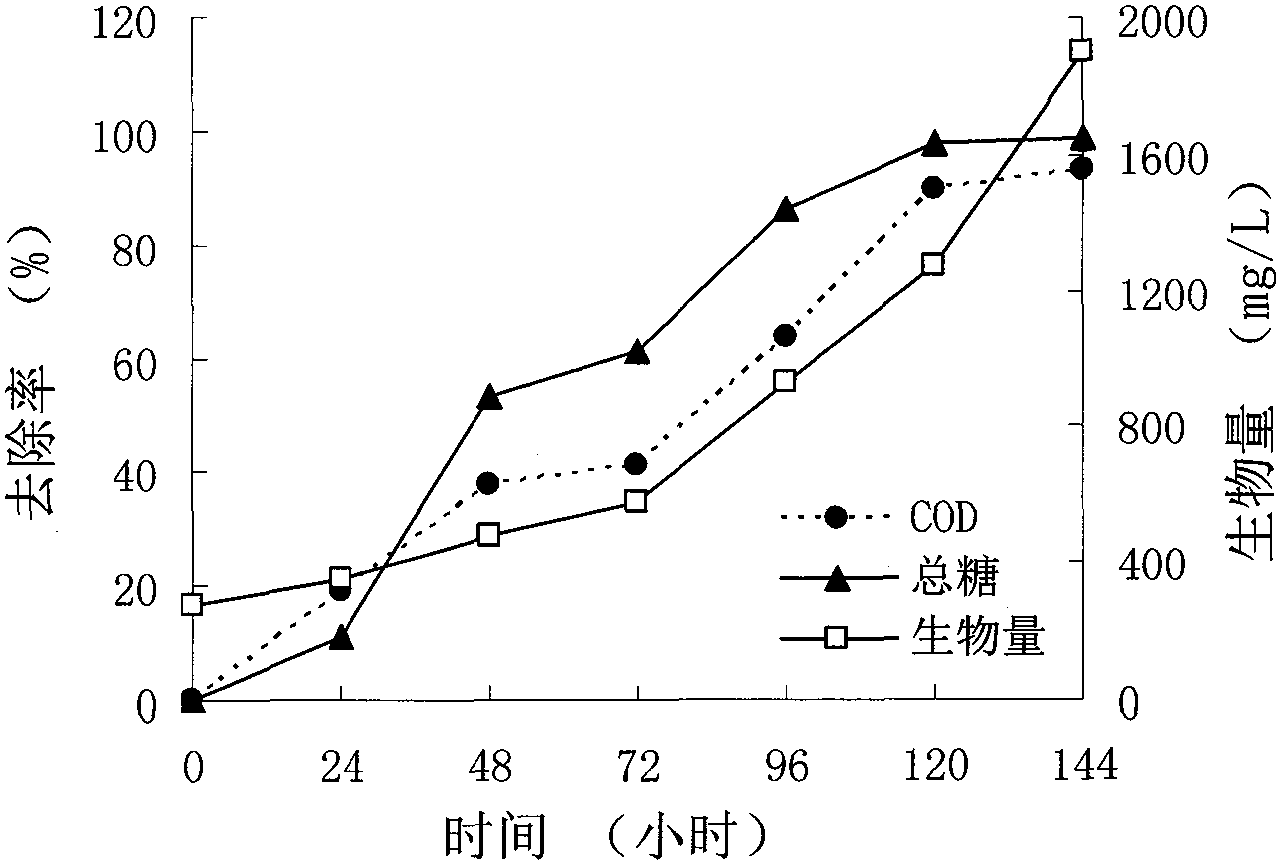

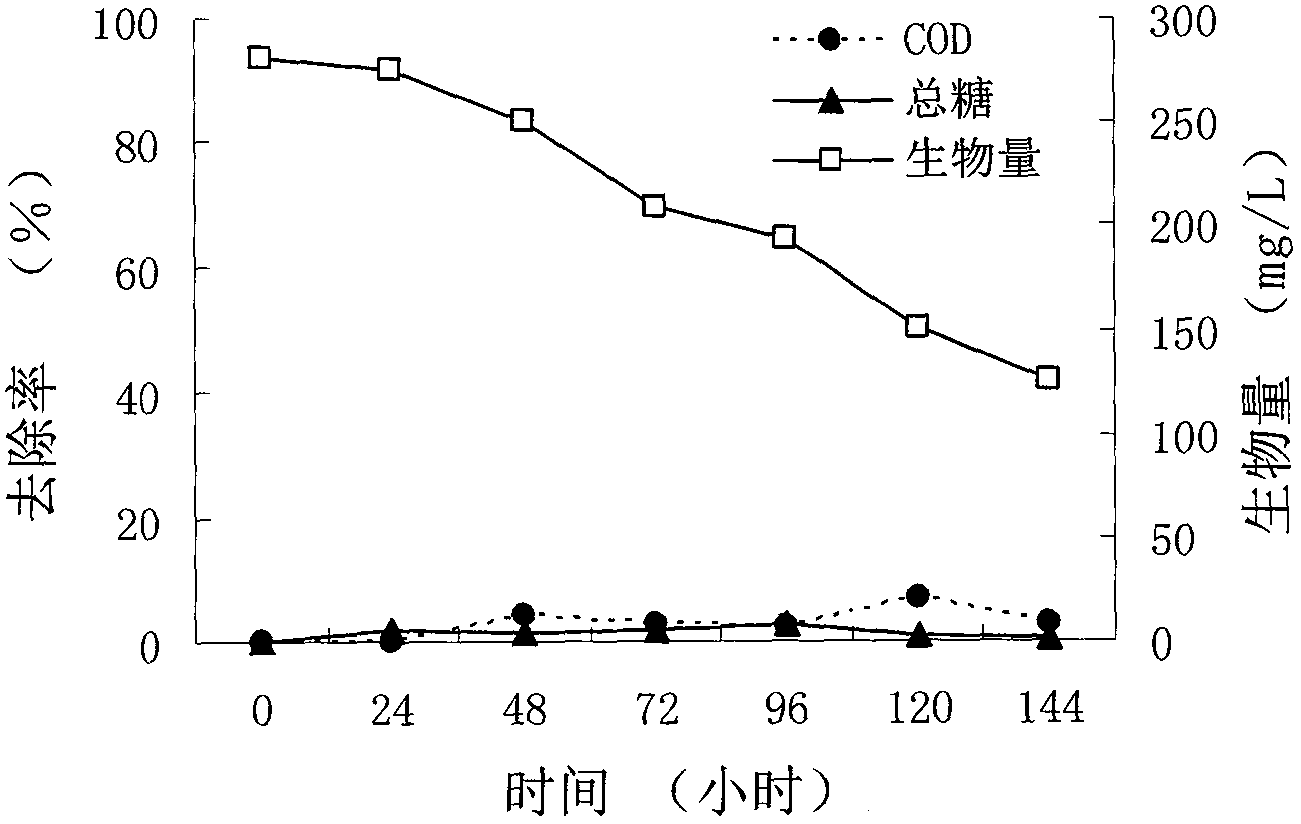

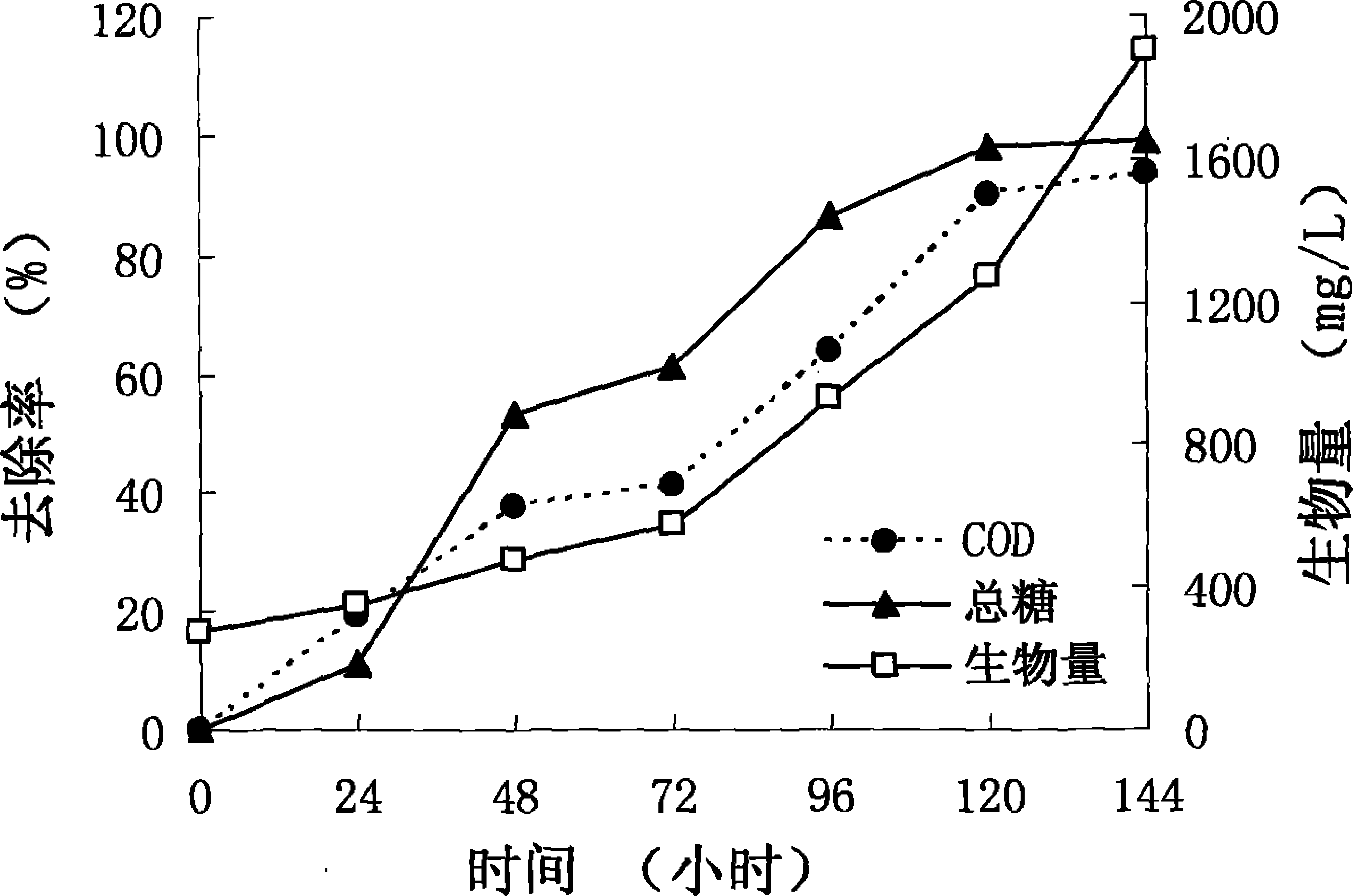

[0013] Specific embodiment 1: The method for utilizing a photosynthetic bacterium to treat starch wastewater and realize the resource utilization of sewage as described in this embodiment is carried out according to the following steps: first, add 200 ~ 600mg / L of malic acid to adjust the pH value of the starch wastewater to about 7.0-9.0, and then add 160-500mg / L of Rhodobacter sphaericus in the logarithmic growth phase to the starch wastewater. Treat under light anaerobic conditions for 120-144 hours, and the treatment temperature is 25-30°C. COD, total sugar and biomass in sewage were measured every 24 hours.

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment differs from Embodiment 1 in that: the starch wastewater concentration selected is 12000 mg / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that: 400 mg / L of malic acid is added to the starch wastewater, and then the pH value of the starch wastewater is adjusted to about 7.0. Others are the same as in the first embodiment.

[0016] Malic acid provides the initial carbon source and energy for the growth of photosynthetic bacteria, which stimulates the activity of photosynthetic bacteria and triggers the production of amylase in photosynthetic bacteria, thereby degrading starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com