Chelated trace element organic fertilizer and production method thereof

A technology for chelating trace elements and a production method, applied in the field of fertilizers, can solve the problems of limited effect, lack of specificity in correcting the current situation of lack of main trace elements in soil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

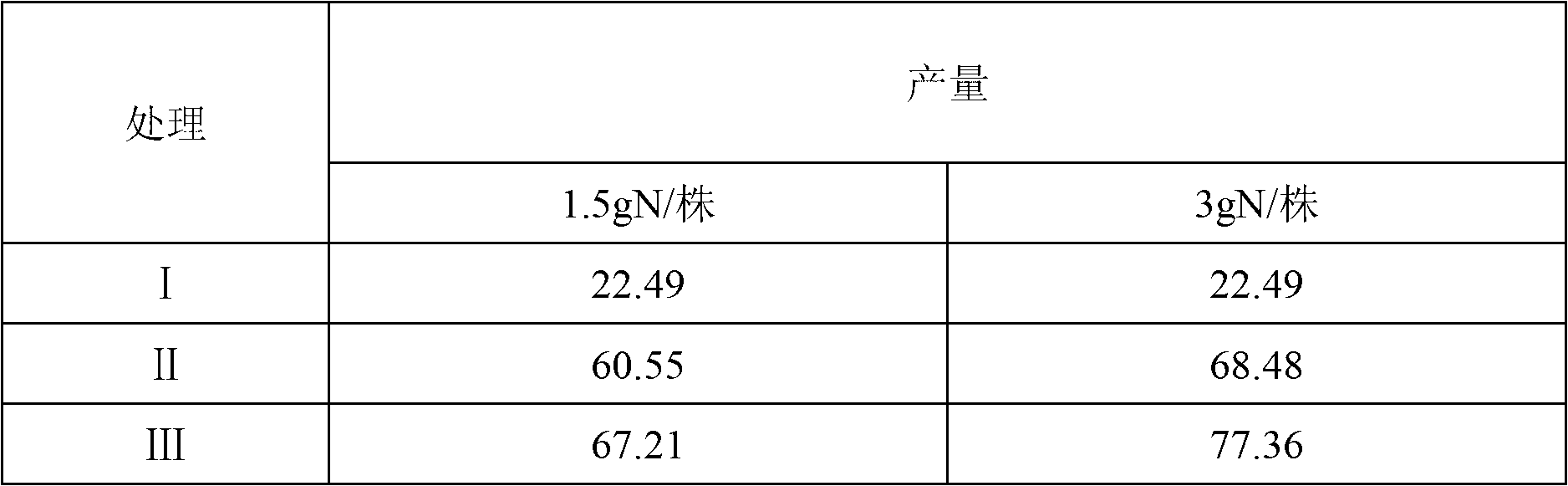

Examples

Embodiment 1

[0081] Embodiment 1: the production of chelated trace element organic fertilizer

[0082] The implementation steps of this embodiment are described as follows:

[0083] A. Preparation of raw materials

[0084] Use the pulverizer sold by Kaifeng Yuda Machinery Equipment Co., Ltd. and the drum screen sold by Shenyang Kexiang Electric Power Environmental Protection Equipment Co., Ltd. under the trade name GT-series drum screen to pulverize the weathered coal, citric acid residue and furfural residue, and sieve The material with a fineness of 60 mesh or more can be obtained.

[0085] B. Preparation of chelated trace element solution

[0086] Prepare 0.20mol / L EDTA-2Na and ZnSO respectively 4 , MnSO 4 or FeSO 4 Then, these solutions are put into the reaction tank according to the volume ratio of 3:1:1:1, and heated by water vapor for 20 minutes, so that the temperature reaches 50°C, and the chelated trace element solution I is obtained.

[0087] C. Preparation of borax soluti...

Embodiment 2

[0095] Embodiment 2: the production of chelated trace element organic fertilizer

[0096] Carry out in the same manner as in Example 1.

[0097] A. Preparation of raw materials

[0098] Use the pulverizer sold by Kaifeng Yuda Machinery Equipment Co., Ltd. and the drum screen sold by Shenyang Kexiang Electric Power Environmental Protection Equipment Co., Ltd. under the trade name GT-series drum screen to pulverize the weathered coal, citric acid residue and furfural residue, and sieve The material with a fineness of 60 mesh or more can be obtained.

[0099]B. Preparation of chelated trace element solution

[0100] Prepare 0.20mol / L DTPA-5Na and ZnSO respectively 4 , MnSO 4 or FeSO 4 Then, these solutions are put into the reaction tank according to the volume ratio of 2.5:1:1:1, and heated by water vapor for 20 minutes, so that the temperature reaches 45°C, and the chelated trace element solution I is obtained.

[0101] C. Preparation of borax solution

[0102] Use borax ...

Embodiment 3

[0109] Embodiment 3: the production of chelated trace element organic fertilizer

[0110] Carry out in the same manner as in Example 1.

[0111] A. Preparation of raw materials

[0112] Use the pulverizer sold by Kaifeng Yuda Machinery Equipment Co., Ltd. and the drum screen sold by Shenyang Kexiang Electric Power Environmental Protection Equipment Co., Ltd. under the trade name GT-series drum screen to pulverize the weathered coal, citric acid residue and furfural residue, and sieve The material with a fineness of 60 mesh or more can be obtained.

[0113] B. Preparation of chelated trace element solution

[0114] Prepare 0.20mol / L DTPA-5Na and ZnSO respectively 4 , MnSO 4 or FeSO 4 Then, these solutions are put into the reaction tank according to the volume ratio of 2:1:0.5:0.5, and heated by water vapor for 16 minutes, so that the temperature reaches 45°C, and the chelated trace element solution I is obtained.

[0115] C. Preparation of borax solution

[0116] Use bor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com