Preparation method for thermoplastic polyimide foaming particle and formed body thereof

A technology of polyimide particles and polyimide particles, which is applied in the field of preparation of polyimide foam materials, can solve the problems of incomplete imidization reaction of foam materials, high open cell content, high production cost, etc. problem, to achieve the effect of overcoming incomplete imidization reaction, easy industrial production, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

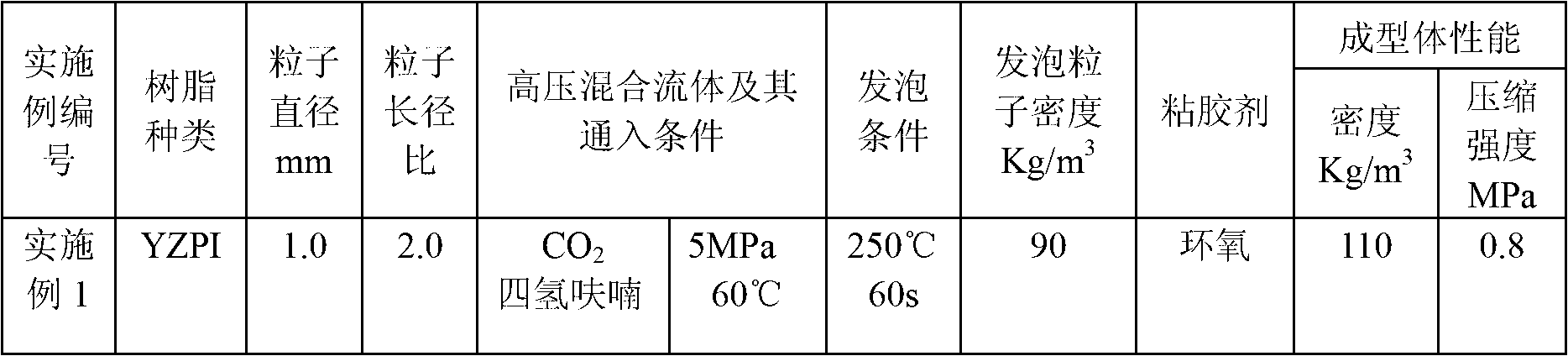

[0037] In this embodiment, the thermoplastic polyimide selects YZPI polyimide developed by Nanjing Yuezi, and the preparation method of the thermoplastic polyimide foamed particles comprises the following steps:

[0038] (1) Inject thermoplastic polyimide particles (YZPI) into a single screw, and melt extrude to prepare thermoplastic polyimide particles with a diameter of 1 mm and an aspect ratio of 2.0;

[0039] (2) Put the thermoplastic polyimide particles into the autoclave, and let the CO with a pressure of 5MPa 2 The high-pressure mixed fluid formed by mixing with tetrahydrofuran makes the high-pressure mixed fluid reach a saturated state in the thermoplastic polyimide particles, and the saturation temperature is 60° C. to obtain saturated thermoplastic polyimide particles;

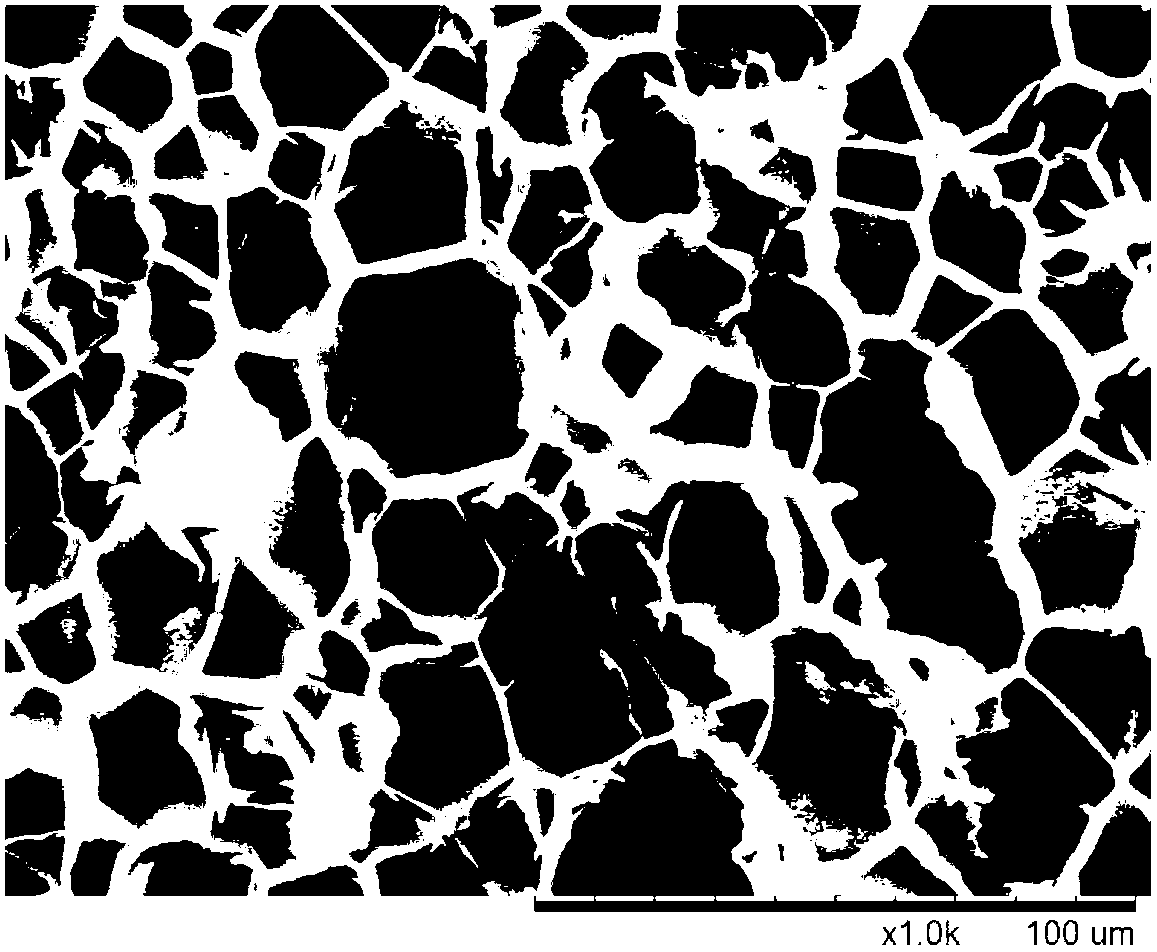

[0040] (3) Put the saturated thermoplastic polyimide particles into a continuous hot air channel at a temperature of 250° C. to foam for 60 seconds to obtain micro-foamed thermoplastic polyimide part...

Embodiment 2

[0045] In this embodiment, the thermoplastic polyimide is selected from the YZPI polyimide developed by Nanjing Yuezi, and the preparation method of the thermoplastic polyimide foamed particles is basically the same as that in Example 1, except that:

[0046] In step (2), the pressure of the high-pressure mixed fluid is 10MPa, and the saturation temperature is 30°C;

[0047] In step (3), the saturated thermoplastic polyimide particles are placed in a continuous hot air channel at a temperature of 280° C. for foaming for 30 seconds to obtain thermoplastic polyimide micro-foamed particles.

[0048] The thermoplastic polyimide micro-expanded particles have a 100% closed-cell structure, the cell size is 15-20 μm, and the cell density is 10 9-10 cells / cm 3 . The apparent density of the thermoplastic polyimide micro-foamed particles is 60Kg / m 3 .

[0049] The above foamed thermoplastic polyimide particles were molded and manufactured, and the specific process was the same as tha...

Embodiment 3

[0052] In this embodiment, the thermoplastic polyimide is selected from the YZPI polyimide developed by Nanjing Yuezi, and the preparation method of the thermoplastic polyimide foamed particles is basically the same as that in Example 1, except that:

[0053] In step (2), the pressure of the high-pressure mixed fluid is 0.5MPa, and the saturation temperature is 120°C;

[0054] In step (3), the saturated thermoplastic polyimide particles are placed in a continuous hot air channel at a temperature of 220° C. for foaming for 120 seconds to obtain micro-expanded thermoplastic polyimide particles.

[0055] The thermoplastic polyimide micro-expanded particles have a 100% closed-cell structure, the cell size is 50-70 μm, and the cell density is 10 6-7 cells / cm 3 . The apparent density of the thermoplastic polyimide micro-foamed particles is 70Kg / m 3 .

[0056] The above foamed thermoplastic polyimide particles were molded and manufactured, and the specific process was the same as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell size | aaaaa | aaaaa |

| Cell density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com