Method for producing biogas through anaerobic digestion of fruit and vegetable waste

A fruit and vegetable waste and anaerobic digestion technology, which is applied in the direction of waste fuel, fermentation, etc., can solve the problems of continuous and stable operation, high water content of fruit and vegetable waste, and heterogeneous materials, so as to promote hydrolysis and acidification efficiency and improve anaerobic digestion Digestion potential, effect of efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

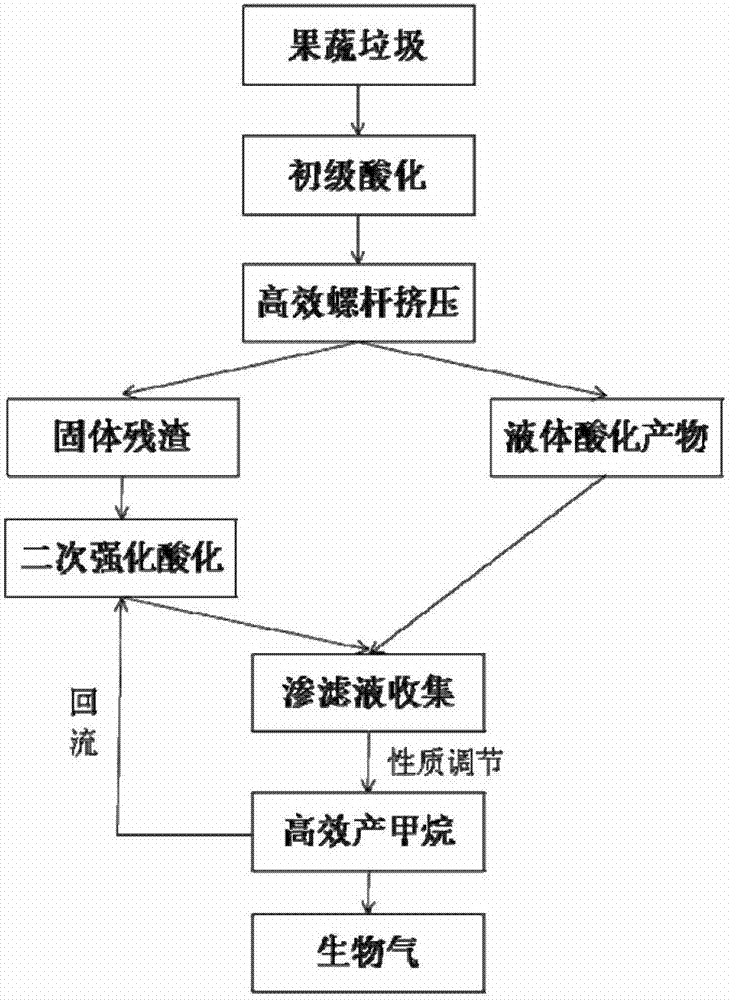

[0020] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to the following examples. See the process figure 1 , The process temperature is controlled at 30-35°C.

[0021] The system includes a screw extrusion system, a 5L primary hydrolysis acidification reactor, a 2L solid residue secondary enhanced hydrolysis acidification reactor, a 5L leachate collection tank, and a 2L methanation reactor. First, 2000g of fruit and vegetable waste is hydrolyzed and acidified in a natural state for 2 days in the primary hydrolysis and acidification pool at a temperature of 35°C, and then transported to the screw extrusion system for solid-liquid separation to obtain about 200g of solid residue and 1800g of primary hydrolysis and acidification liquid Materials and liquid materials enter the leachate collection tank, put the solid residue into the secondary enhanced hydrolysis acidification reactor, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com