Method for spinning high-strength polyester staple fibers by using waste polyester

A polyester staple fiber, high-strength technology, applied in the field of polyester staple fiber, can solve the problems of limited resources and high cost, and achieve the effect of eliminating static electricity, high productivity and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now take the method of spinning high-strength 1.2-denier regenerated polyester staple fiber from waste polyester as an example to illustrate the specific implementation of the present invention.

[0015] The method for spinning high-strength 1.2-denier regenerated polyester staple fiber from waste polyester, the main process includes: vacuum drying, extrusion melting, filtering, high-pressure spinning, cooling with ring blowing, drafting, tension heat setting, curling and relaxation heat setting, this The implementation method is to make the following improvements and adjustments in the above-mentioned conventional process flow:

[0016] (1) On the basis of the conventional spinning process conditions, a sea sand filter is added in the spinning assembly, so that the molten material is precisely filtered through the sea sand filter, so as to obtain a clean melt consistent with the original material.

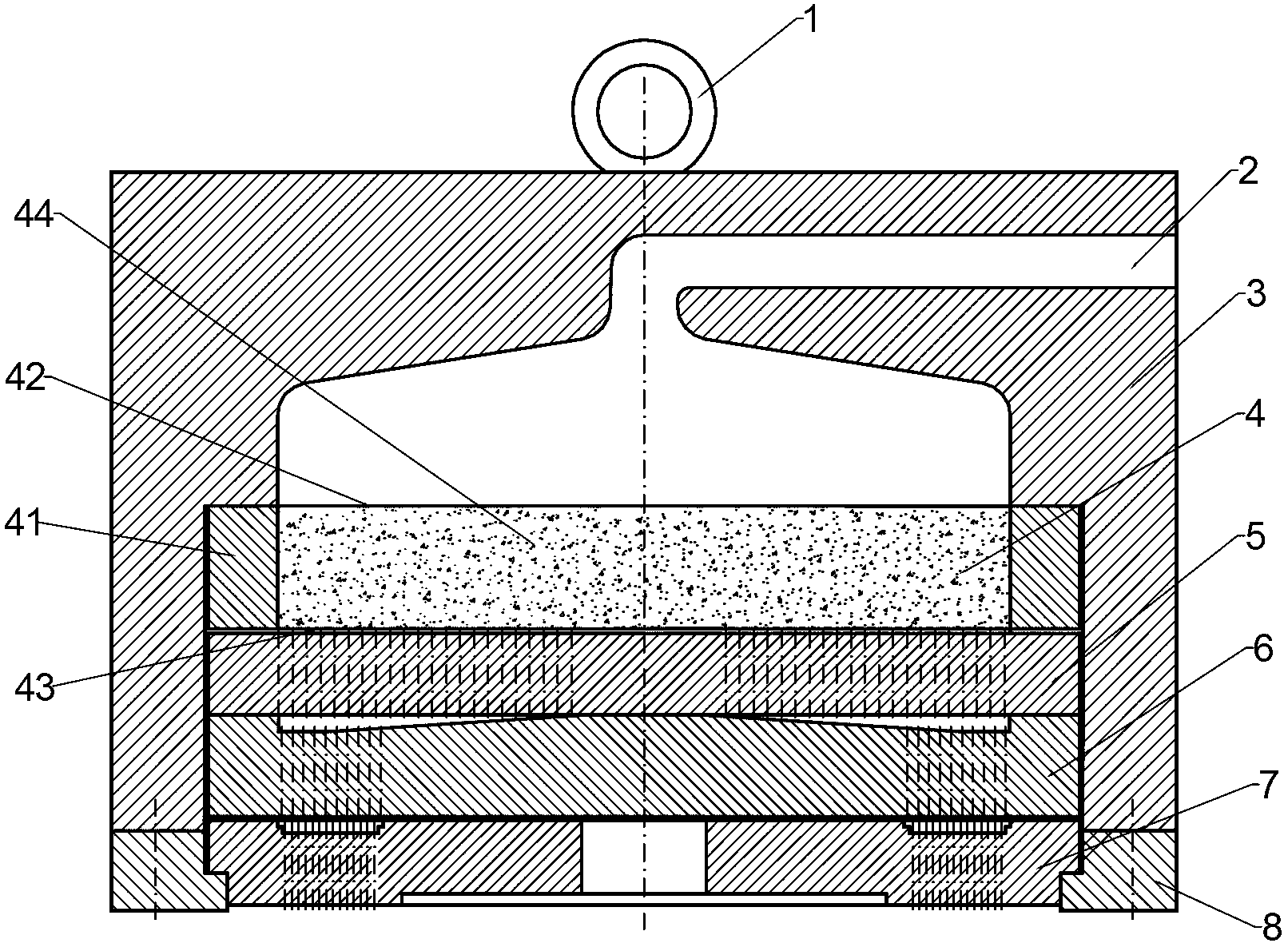

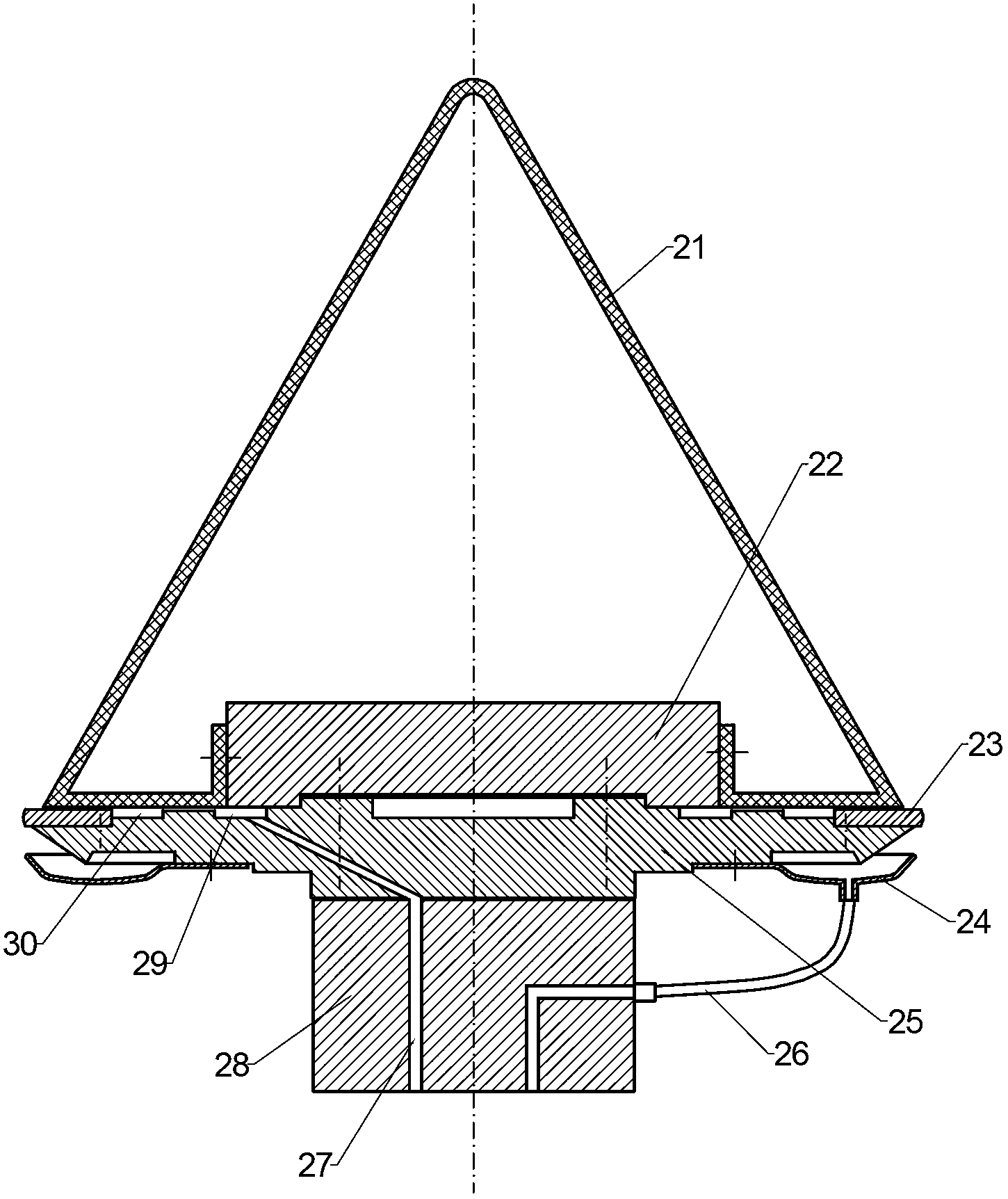

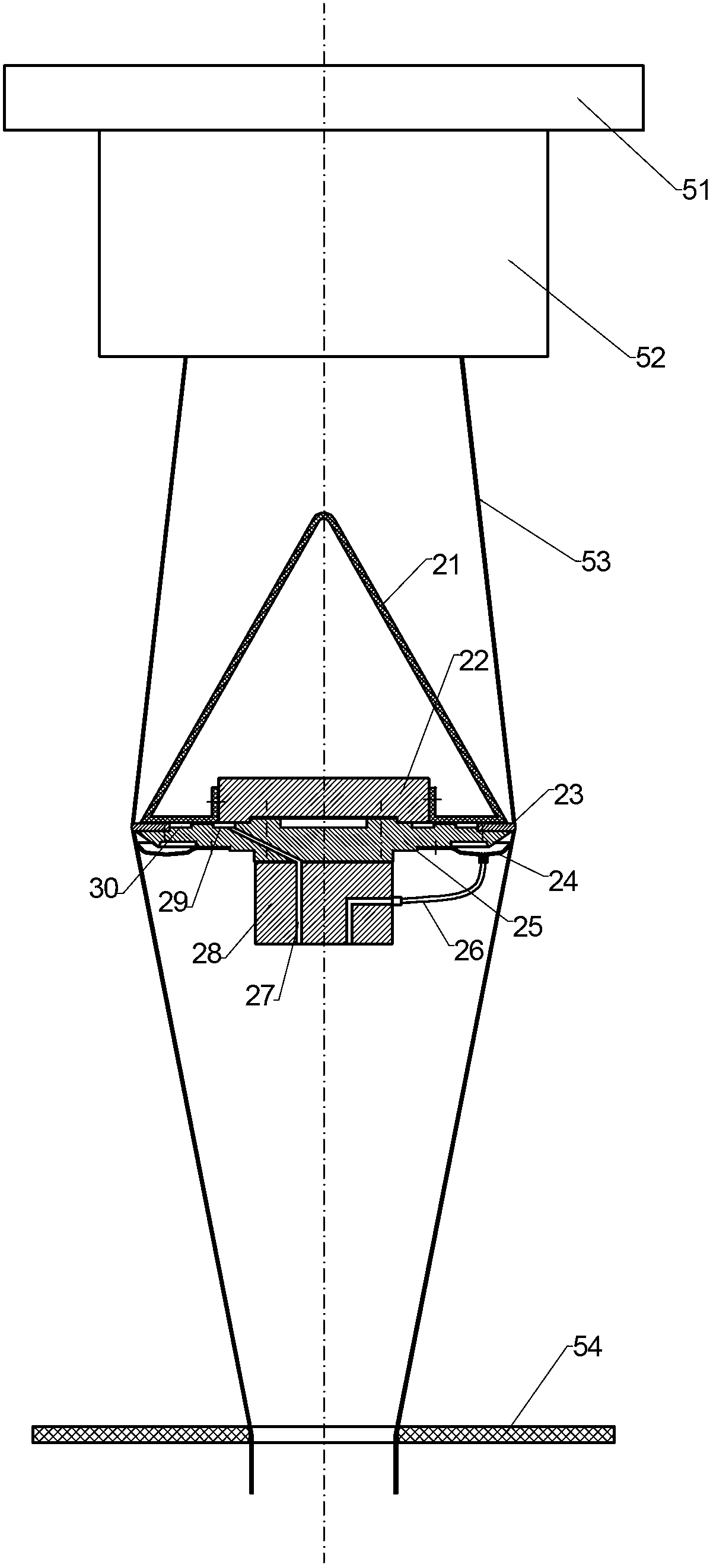

[0017] refer to figure 1 , the existing spinning assembly is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com