System and method for collaborative garbage disposal of cement clinker production line

A cement clinker and co-processing technology, which is applied in cement production, clinker production, combustion methods, etc., can solve the problems of complicated follow-up processing, high requirements on the size of waste entering the furnace, and competition for hot air, etc., so as to increase the temperature of waste incineration , Eliminate heavy metal hazards and reduce smoke emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

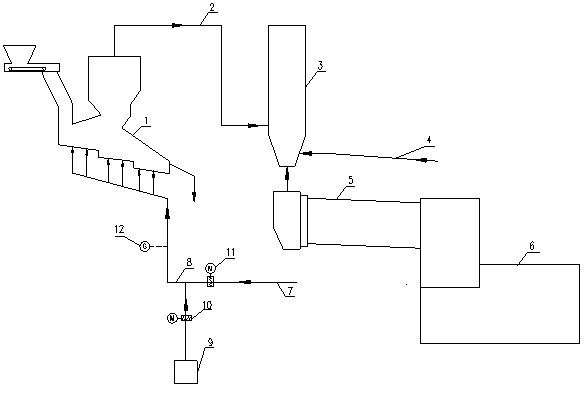

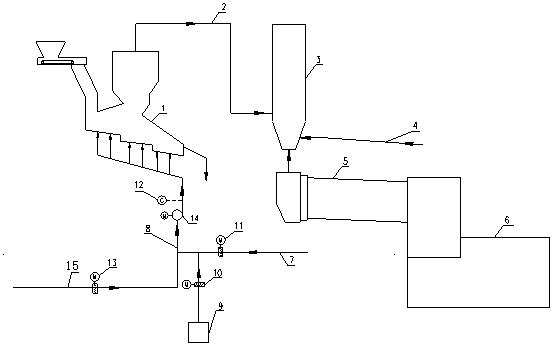

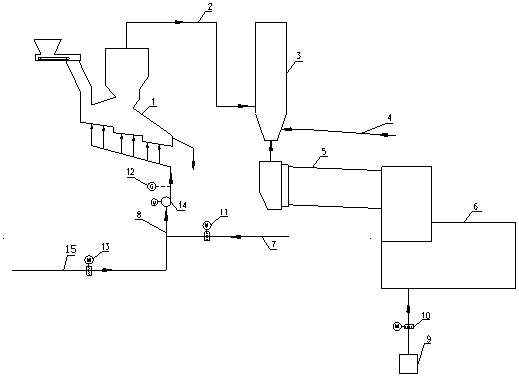

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1 to Figure 3 as shown, Cement clinker production line co-processing waste system Including garbage incinerator 1, flue gas pipe 2, (cement clinker production line) decomposition furnace 3, tertiary air pipe 4, rotary kiln 5, grate cooler 6, hot air pipe 7, air supply pipe 8, and oxygen-enriched system 9 , the oxygen-enriched system 9 is arranged on the air supply pipeline 8 of the garbage incinerator, and an oxygen-enriched pipeline valve 10 is provided between the air supply pipeline 8 and the oxygen-enriched system 9, and an oxygen-enriched pipeline valve 10 is arranged between the hot air pipeline 7 and the air supply pipeline 8. There is a hot-blast pipeline valve 11, and the degree of system oxygen enrichment is regulated by the oxygen-enriched pipeline valve 10 and the hot-blast pipeline valve 11.

[0028] As a further improvement of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com