Superfine crystal silicon battery structure

A crystalline silicon battery, ultra-thin technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of single optimization of photogenerated carrier generation, transportation and collection, to enhance the effect of light trapping in the body, and eliminate shading loss , Reduce the effect of recombination loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

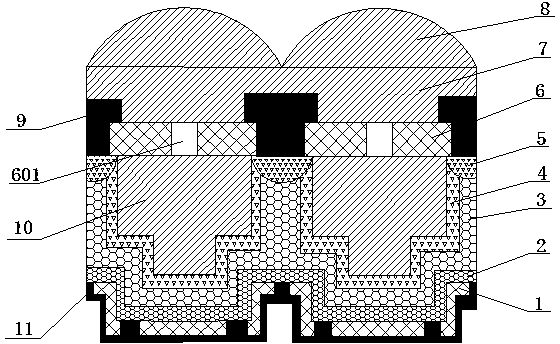

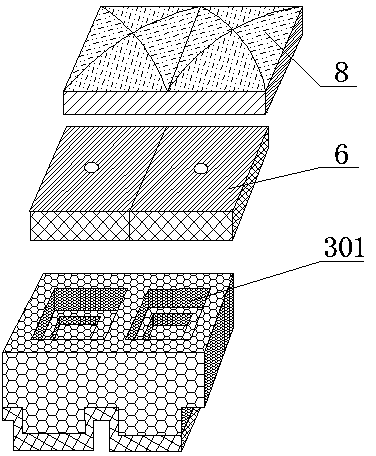

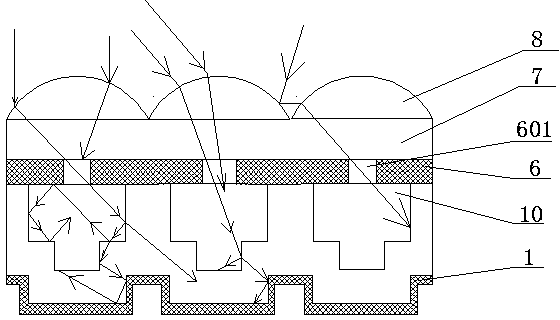

[0028] like figure 1 , figure 2 As shown, the ultra-thin crystalline silicon cell structure includes a P-type crystalline silicon wafer 3 with a stepped etching groove 301 on the front side, and an N-type doped region on the P-type crystalline silicon wafer 3 along the inner wall of the etching groove 301 4. A PN junction is formed through the N-type doped region 4, and a dielectric 10 is filled in the etching groove 301. The dielectric 10 is filled with polyimide (it can also be photoresist, magnesium fluoride, silicon dioxide, etc.) , aluminum oxide, silicon nitride, tantalum pentoxide, zinc sulfide or titanium dioxide), and a P+-type doped region 2 is provided on the back of the P-type crystalline silicon wafer 3 . An N+ doped region 5 is provided on the N-type doped region around the etching groove 301 on the front side of the silicon wafer 3, and an upper surface is provided on the upper surface of the dielectric 10 and the N-+ type doped region 5 on the front side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com