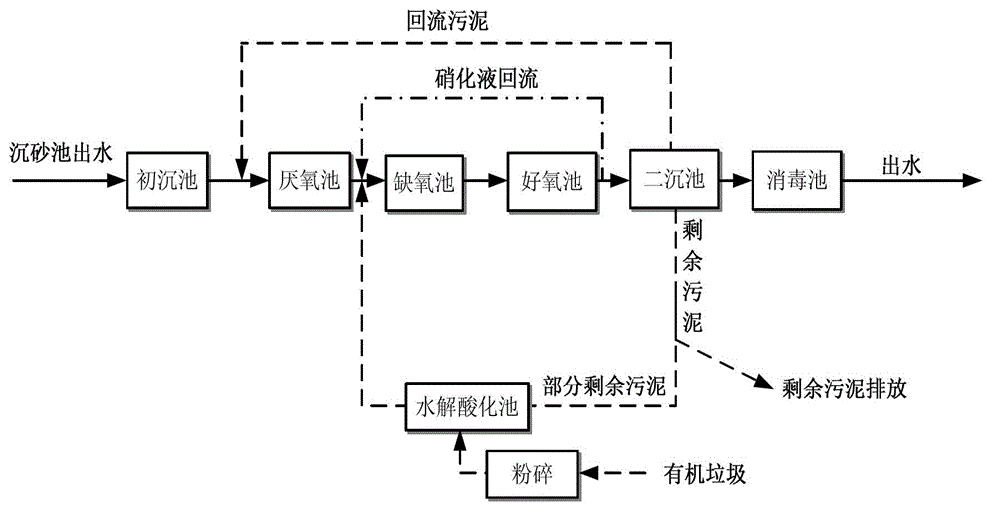

Method for hydrolyzing and acidifying residual sludge and organic wastes and supplementing carbon sources to promote biological nitrogen removal and application thereof

A technology for organic waste, hydrolysis and acidification, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc. Proper disposal and other issues to achieve the effect of reducing operating costs, significant environmental and economic benefits, and reducing sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] After degreasing and pulverizing, the mixture of kitchen waste (commonly used for degreasing and crushing in waste treatment) and excess sludge, the solid-to-liquid ratio is 1:15 (mass of organic waste: volume of excess sludge), and the amount of excess sludge is 5% of the incoming water flow. The two enter the hydrolytic acidification tank for hydrolytic acidification reaction for 24 hours. After the reaction, the VFAs in the mixed solution can reach 4825mg / L (90% of which is acetic acid). The hydraulic retention time of the oxygen pool is 2h. The whole process runs continuously for 3 months in summer, and the denitrification effect is stable. The monitoring data found that the influent chemical oxygen demand (COD) is 100-200mg / L, the total nitrogen (TN) is 40-50mg / L, the secondary sedimentation tank effluent COD50-60mg / L, TN8-12mg / L, and the effluent reaches the first grade A standard (GB18918-2002), and reduce the amount of residual sludge discharge, to achieve slu...

Embodiment 2

[0020] After degreasing and crushing, the mixture of kitchen waste (commonly used for degreasing and crushing in waste treatment) and excess sludge, the solid-liquid ratio is 1:20 (mass of organic waste: volume of excess sludge), and the amount of excess sludge is 8% of incoming water flow. The two enter the hydrolytic acidification tank for 30 hours of hydrolytic acidification reaction. After the reaction, the VFAs in the mixed solution can reach 6025mg / L (91% of which is acetic acid). The hydraulic retention time of the oxygen pool is 4h. The whole process runs continuously for 3 months in autumn, and the denitrification effect is stable. The monitoring data found that the influent chemical oxygen demand (COD) is 100-200mg / L, the total nitrogen (TN) is 30-45mg / L, the secondary sedimentation tank effluent COD50-60mg / L, TN10-12mg / L, and the effluent reaches the first grade A standard (GB18918-2002).

Embodiment 3

[0022] Mixture of crushed vegetable waste (commonly used in waste treatment) and excess sludge, solid-liquid ratio of 1:25 (organic waste mass: excess sludge volume), excess sludge volume of 6% of influent flow . The two enter the hydrolytic acidification tank for hydrolytic acidification reaction for 48 hours. After the reaction, the VFAs in the mixed solution can reach 7514mg / L (89% of which is acetic acid). The hydraulic retention time of the oxygen tank is 3h. The whole process runs continuously for 3 months in winter, and the denitrification effect is stable. The monitoring data found that the influent chemical oxygen demand (COD) is 100-200mg / L, the total nitrogen (TN) is 30-45mg / L, the secondary sedimentation tank effluent COD40-50mg / L, TN 10-15mg / L, and the effluent reaches a Class A standard (GB18918-2002).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com