Preparation process of trimethyl idodine silicon hydride

A technology of trimethyliodosilane and preparation process, which is applied in the fields of compounds, chemical instruments and methods, organic chemistry, etc. It is difficult to control and other problems, so as to achieve the effect of improving product conversion rate, good mass transfer and heat transfer effect, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

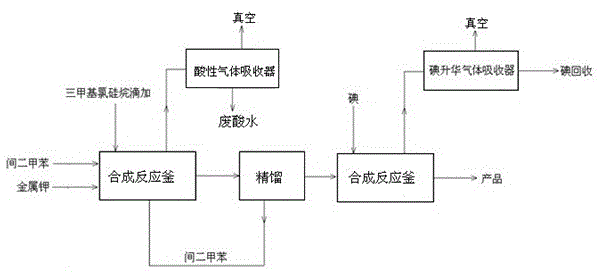

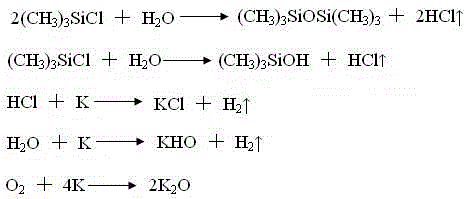

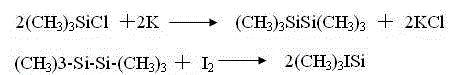

[0032] As shown in the figure, the preparation process of the preparation process of iodotrimethylsilane is:

[0033] 1. Preparation of hexamethyldisilane: firstly, to a volume of 1.5m 3 Put 550kg of m-xylene and 100kg of metal potassium into the enamel stirred tank, mix and stir; then add 320kg of trimethylchlorosilane dropwise into the stirred tank, and the dropwise addition is completed within two hours, and the reaction is carried out under a slight positive pressure of 0~0.02MPa , the temperature is controlled below 120°C; stop stirring after the reaction is over, and when the temperature drops to 50°C, the materials in the kettle are introduced into the washing kettle; the unreacted hydrogen chloride gas is absorbed by alkaline water through the falling film absorber;

[0034] 2. Water washing: Add 380 kg of production water to the washing kettle, and control the temperature of the washing kettle to 100°C; after the completion of static sedimentation, the supernatant liq...

Embodiment 2

[0038] As shown in the figure, the preparation process of the preparation process of iodotrimethylsilane is:

[0039] 1. Preparation of hexamethyldisilane: firstly, to a volume of 1.5m 3 Put 580kg of m-xylene and 120kg of metal potassium into the enamel stirred tank, mix and stir; then add 340kg of trimethylchlorosilane dropwise into the stirred tank, and the dropwise addition is completed within two hours, and the reaction is carried out under a slight positive pressure of 0~0.02MPa , the temperature is controlled below 120°C; stop stirring after the reaction is over, and when the temperature drops to 50°C, the materials in the kettle are introduced into the washing kettle; the unreacted hydrogen chloride gas is absorbed by alkaline water through the falling film absorber;

[0040] 2. Water washing: add 400 kg of production water to the washing kettle, and control the temperature of the washing kettle to 100°C; after the completion of static sedimentation, the supernatant liq...

Embodiment 3

[0044] As shown in the figure, the preparation process of the preparation process of iodotrimethylsilane is:

[0045] 1. Preparation of hexamethyldisilane: firstly, to a volume of 1.5m 3 Put 600kg of m-xylene and 140kg of metal potassium into the enamel stirred kettle, mix and stir; then add 360kg of trimethylchlorosilane dropwise into the stirred kettle, and the dropwise addition is completed within two hours, and the reaction is carried out under a slight positive pressure of 0~0.02MPa , the temperature is controlled below 120°C; stop stirring after the reaction is over, and when the temperature drops to 50°C, the materials in the kettle are introduced into the washing kettle; the unreacted hydrogen chloride gas is absorbed by alkaline water through the falling film absorber;

[0046] 2. Water washing: add 400 kg of production water to the washing kettle, and control the temperature of the washing kettle to 100°C; after the completion of static sedimentation, the supernatant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com