Preparation process of trimethylethoxysilane

A technology for the preparation of trimethylethoxysilane and its preparation process, which is applied in the field of preparation of trimethylethoxysilane, and can solve the problems of increased by-products and waste residues, increased addition of neutralizing agents, and increased waste residues generated. , to achieve the effect of improved distillation yield, easy control and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

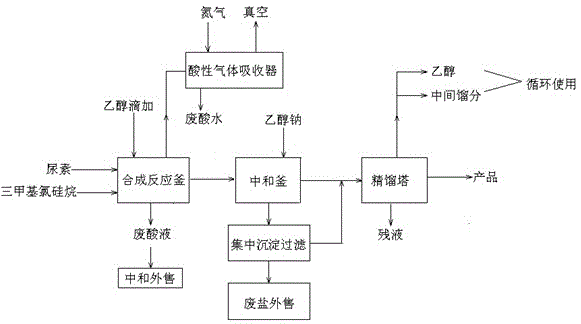

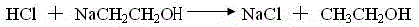

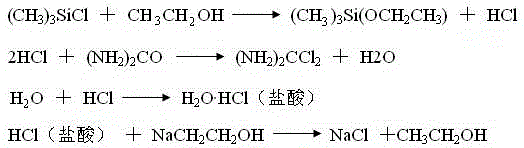

[0032] Embodiment 1: As shown in the figure, the preparation process steps of trimethylethoxysilane are:

[0033] 1. Response: First, to 1m 3 Put 700kg of trimethylchlorosilane and 450kg of urea into the enamel stirred tank, mix and stir; then add 400kg of ethanol dropwise into the stirred tank, and the dropwise addition is completed within two hours. Or the method of jacket cold water cooling is controlled below 60 °C; the hydrogen chloride gas that has not reacted with urea is absorbed by water through the falling film absorber; after the reaction is completed, stop stirring, keep the layers for 20 minutes, release the acidic liquid at the bottom, and remove the crude product from the upper layer Import the neutralization kettle.

[0034] 2. Neutralization: Analyze the content of trimethylethoxysilane and hydrogen chloride before neutralization to determine the amount of neutralizing agent. The neutralizing agent is potassium alkoxide, sodium alkoxide or alkaline earth meta...

Embodiment 2

[0037] Embodiment two: as shown in the figure, the preparation process steps of trimethylethoxysilane are:

[0038] 1. Response: First, to 1m 3 Put 700kg of trimethylchlorosilane and 450kg of urea into the enamel stirred tank, mix and stir; then add 410kg of ethanol dropwise into the stirred tank, and the dropwise addition is completed within two hours. Below ℃, the temperature is controlled below 60℃ by means of dropping speed or cooling with jacketed cold water; the hydrogen chloride gas that has not reacted with urea is absorbed by water through the falling film absorber; after the reaction is over, stop stirring, keep the stratification for 60 minutes, and release the bottom Acidic liquid, the crude product of the upper layer is introduced into the neutralization tank.

[0039] 2. Neutralization: Analyze the content of trimethylethoxysilane and hydrogen chloride before neutralization to determine the amount of neutralizing agent. The neutralizing agent is potassium alkoxi...

Embodiment 3

[0042] Embodiment three: as shown in the figure, the preparation process steps of trimethylethoxysilane are:

[0043] 1. Response: First, to 1m 3 Put 700kg of trimethylchlorosilane and 450kg of urea into the enamel stirred tank, mix and stir; then add 430kg of ethanol dropwise into the stirred tank, and the dropwise addition is completed within two hours. Below ℃, the temperature is controlled below 60℃ by way of dropping speed or cooling with jacketed cold water; the hydrogen chloride gas that has not reacted with urea is absorbed by water through the falling film absorber; after the reaction is over, stop stirring, keep the stratification for 45 minutes, and release the bottom Acidic liquid, the crude product of the upper layer is introduced into the neutralization tank.

[0044] 2. Neutralization: analyze the content of trimethylethoxysilane and hydrogen chloride before neutralization to determine the amount of neutralizing agent. The neutralizing agent is potassium alkoxi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap