Tapered-waveguide-assisted cascade long-period waveguide grating sensor and preparation method thereof

A technology of long-period gratings and waveguide gratings, which is applied to optical waveguides, light guides, and optical devices to transmit sensing components and light guides. The effect of response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

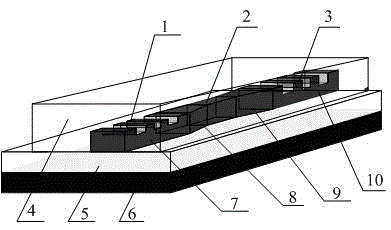

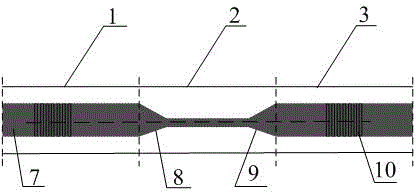

[0024] The cascaded long-period waveguide grating sensor assisted by tapered waveguide is a cascaded long-period grating based on tapered waveguide, see figure 1 Stereogram and figure 2 Top view, composed of three parts: the first long-period waveguide grating (1) is connected to the second long-period waveguide grating (3) through a tapered waveguide (2), and the core refractive index of the three parts is the same, and their The cladding refractive index is also the same.

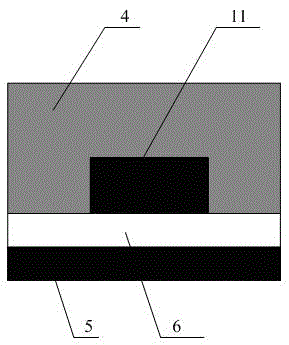

[0025] For the first long-period waveguide grating (1) and the second long-period waveguide grating (3) of the above-mentioned cascaded long-period waveguide gratings assisted by tapered waveguides, see image 3 front view and Figure 4 Side view, etched from polymer waveguide with tapered waveguide, consisting of upper cladding (4), lower cladding (5), substrate (6), core (7) and.

Embodiment 2

[0027] The preparation method of the above-mentioned sensor is as follows: the above-mentioned cascaded long-period waveguide grating based on the tapered waveguide is etched from a polymer waveguide with a tapered waveguide, and first made on silicon-based silicon dioxide by ultraviolet lithography technology. The substrate transfers the tapered waveguide-assisted cascaded waveguide pattern to the photoresist, and then uses the reactive ion etching method to etch the tapered waveguide-assisted cascaded waveguide into a tapered waveguide-assisted cascaded long-period waveguide raster. Its specific process and process steps are as follows:

[0028] 1) Using plasma chemical vapor deposition to deposit a layer of silicon dioxide on the substrate silicon wafer as the lower cladding layer of the optical waveguide, thereby forming a silicon-based silicon dioxide substrate;

[0029] 2) Coat the photoresist uniformly on the surface of silicon-based silicon dioxide by spin coating met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com