In-wafer reliability screening method for GaN HEMT (High Electron Mobility Transistor) device

A reliability and device technology, applied in the direction of single semiconductor device testing, optical testing flaws/defects, etc., can solve the problems of reducing the electron gas concentration in the lower channel, device performance degradation, drain current and transconductance drop, etc., to achieve shortening The time of screening, the effect of improving work efficiency and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

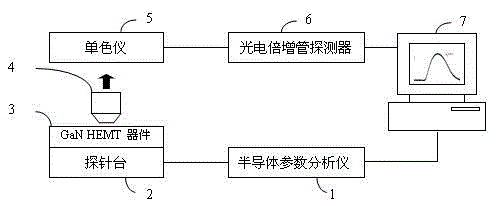

[0025] According to step 1 in the above-mentioned embodiment, a GaN HEMT device on-chip electroluminescence spectrum test platform is built.

[0026] GaN HEMT device on-chip electroluminescence calibration: turn off all light sources in the test site, do not apply any bias voltage to the GaN HEMT device, use the microscopic spectrum test system to test its response spectrum to black body radiation, and record the data Intensity0-λ in the computer .

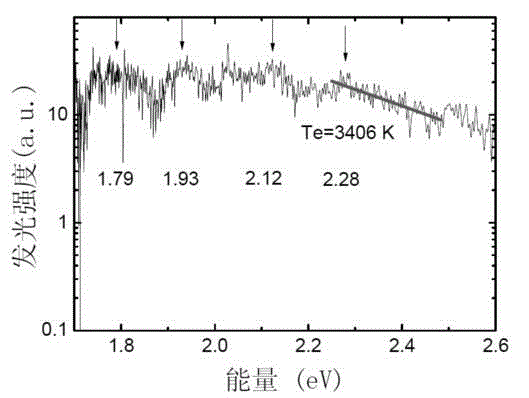

[0027] Selection of luminous intensity test conditions for GaN HEMT devices: First, test the transfer characteristics Ids-Vgs of the device to obtain the pinch-off voltage Vp=-1.76V of the device; then, make the gate voltage Vgs=-1.8V and gradually increase the drain voltage Vds At the same time, observe the device image in the computer. When the device starts to emit light, the leakage voltage is Vdsc=40V; select the leakage voltage Vds=35V test condition (the device does not emit light at this time), and measure the relationship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com