Gd1-xCaxBiO3 buffering layer of high temperature superconducting coated conductor and preparation method thereof

A technology of coated conductors and high temperature superconductivity, which is applied in the directions of superconductivity/high conductivity conductors, the usage of superconductor elements, and cable/conductor manufacturing, etc. , to achieve the effect of low cost, suitable for large-scale deposition, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

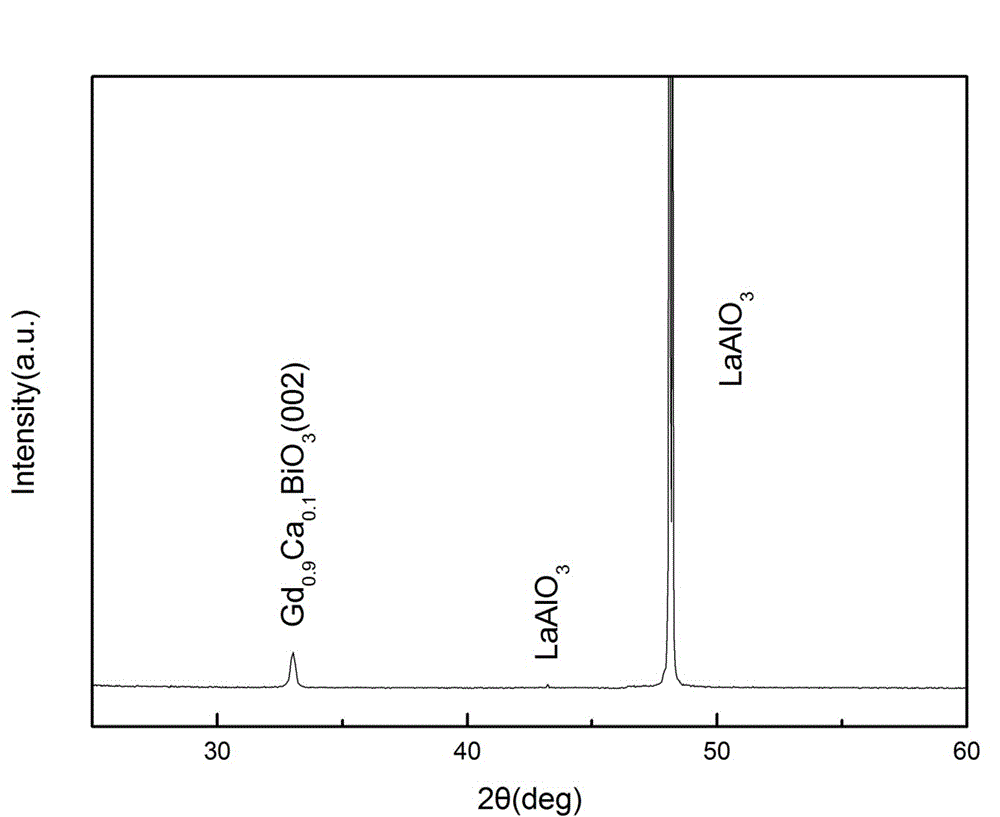

[0029] The invention provides a buffer layer Gd of a high-temperature superconducting coated conductor 0.9 Ca 0.1 BiO 3 . And a preparation of high temperature superconducting coating conductor Gd 0.9 Ca 0.1 BiO 3 The method for buffer layer thin film, its step is:

[0030] a.Gd 0.9 Ca 0.1 BiO 3 Preparation of buffer layer colloid: the precursors Gd, Ca, Bi nitrate are dissolved in an appropriate amount of polyacrylic acid (PAA) at a cationic concentration of 0.9:0.1:1 to obtain an organic system. The total molar concentration of the final solution is 0.2mol / L.

[0031] b.Gd 0.9 Ca 0.1 BiO 3 Buffer layer coating, drying and decomposition: coating the colloid prepared in step a on LaAlO 3 On the single crystal substrate, dry at 100°C; then place it in a sintering furnace, slowly raise the furnace temperature from room temperature to 180°C in the air, and raise it to 300°C at a speed of 0.1°C / min, and then Raise to 540°C at a rate of 0.1°C / min and keep warm for 30 ...

Embodiment 2

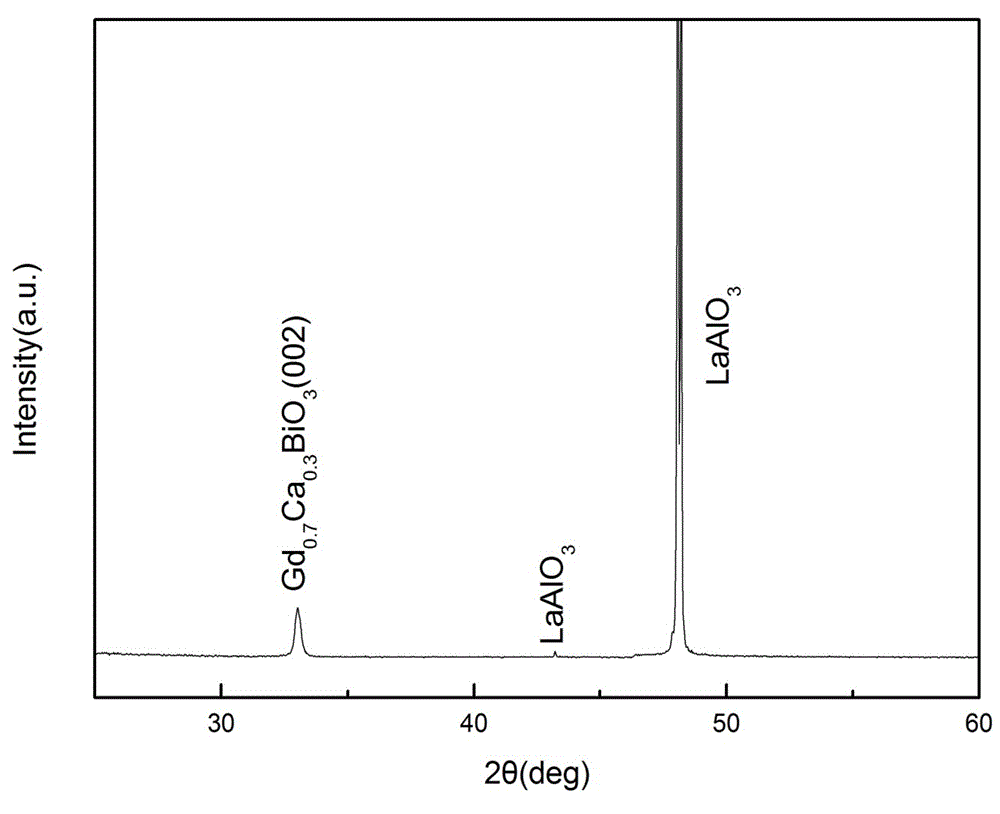

[0036] The invention provides a buffer layer Gd of a high-temperature superconducting coated conductor 0.7 Ca 0.3 BiO 3 . And a preparation of high temperature superconducting coating conductor Gd 0.7 Ca 0.3 BiO 3 The method for buffer layer thin film, its step is:

[0037] a.Gd 0.7 Ca 0.3 BiO 3 Preparation of buffer layer colloid: the precursor Gd, Ca, Bi nitrate is dissolved in an appropriate amount of polyacrylic acid (PAA) according to the cation concentration of 0.7:0.3:1, so as to obtain an organic system. The total molar concentration of the final solution is 0.2mol / L.

[0038] b.Gd 0.7 Ca 0.3 BiO 3 Buffer layer coating, drying and decomposition: coating the colloid prepared in step a on LaAlO 3 on a single crystal substrate, and then dried at 120°C; then placed in a sintering furnace, and the furnace temperature was slowly raised from room temperature to 200°C in the air, and then raised to 320°C at a speed of 2°C / min, and then Raise to 550°C at a rate of...

Embodiment 3

[0043] The invention provides a buffer layer Gd of a high-temperature superconducting coated conductor 0.6 Ca 0.4 BiO 3 . And a preparation of high temperature superconducting coating conductor Gd 0.6 Ca 0.4 BiO 3 The method for buffer layer thin film, its step is:

[0044] a.Gd 0.6 Ca 0.4 BiO 3 Preparation of buffer layer colloid: the precursors Gd, Ca, Bi nitrate are dissolved in an appropriate amount of polyacrylic acid (PAA) at a cation concentration of 0.6:0.4:1 to obtain an organic system. The total molar concentration of the final solution is 0.2mol / L.

[0045] b.Gd 0.6 Ca 0.4 BiO 3 Buffer layer coating, drying and decomposition: coating the colloid prepared in step a on LaAlO 3 On the single crystal substrate, dry at 150°C; then place it in a sintering furnace, slowly raise the furnace temperature from room temperature to 230°C in the air, and increase it to 340°C at a speed of 1°C / min, and then Raise to 560°C at a rate of 1°C / min and keep warm for 30 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com