Coil for stainless steel framed Nb3Sn superconducting solenoid

A technology of solenoid coils and superconducting magnets, applied in superconducting magnets/coils, magnetic objects, plastic/resin/wax insulators, etc., to achieve the effects of stable ceramic coating, improved thermal shock resistance, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

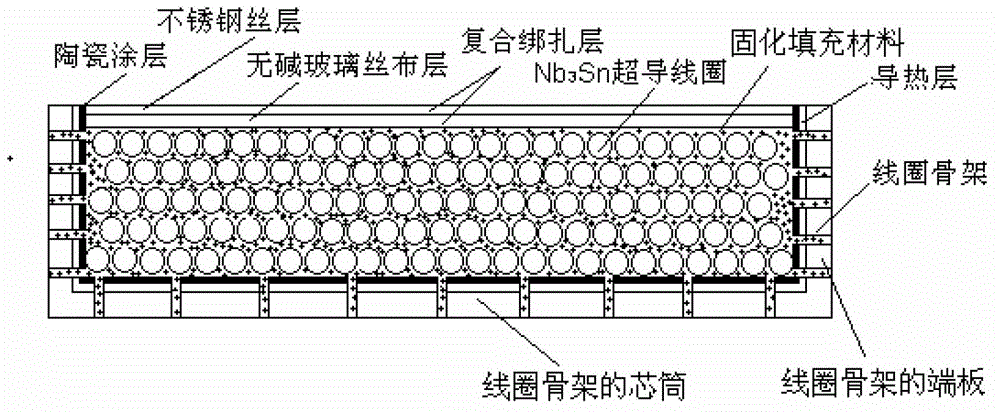

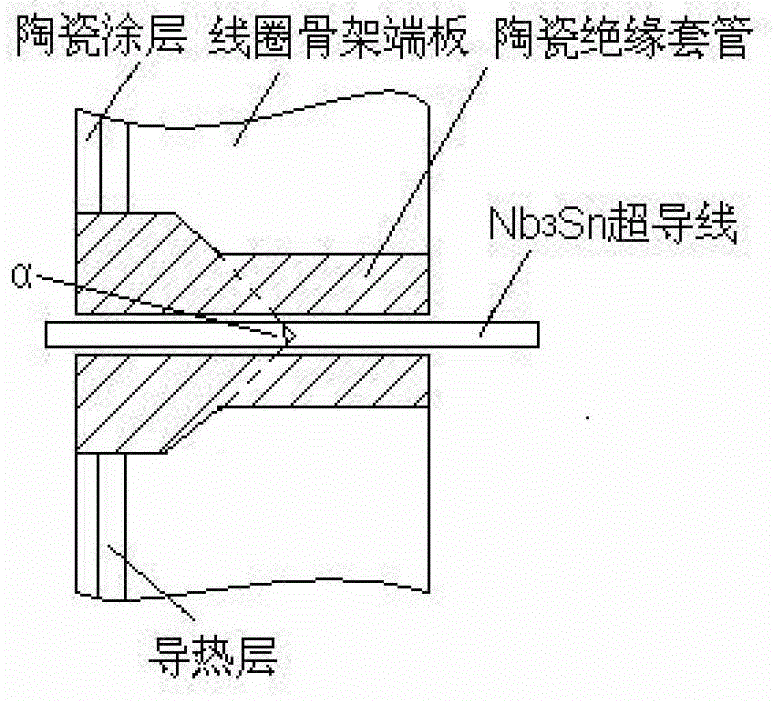

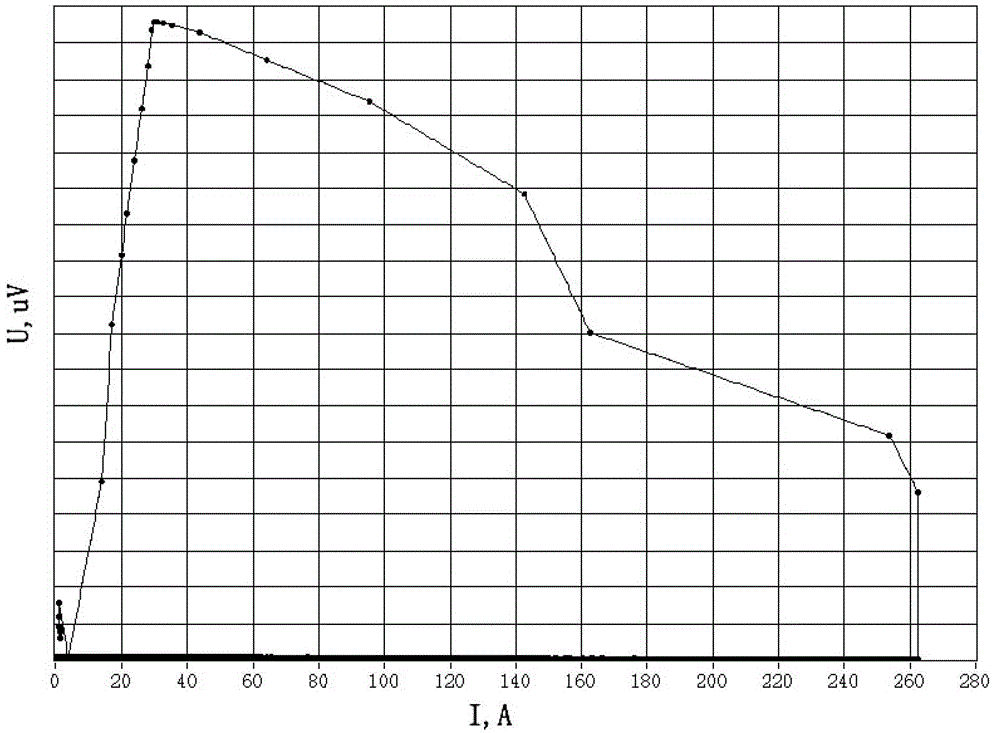

[0034] The wire of the solenoid coil of the superconducting magnet is made of Nb in bronze process 3 Sn superconducting wire, the wire is insulated by an alkali-free glass cloth sleeve. The superconducting wire has a bare diameter of 0.9mm and an insulated diameter of 1.05mm. Nb 3 The inner diameter of the Sn coil is 41mm, the outer diameter is 64mm, and the length is 150mm. There are 12 layers of superconducting wires in the coil, with a total of about 1655 turns. The coil bobbin is made of non-magnetic stainless steel, and the coil bobbin is composed of a straight tubular core barrel and end plates located at both ends of the core barrel. Both the outer surface of the core barrel and the inner side of the end plate have a silver heat conduction layer and an alumina ceramic coating prepared by a plasma spraying process; the heat conduction layer is located between the ceramic coating and the skeleton. Nb wound with ceramic coating 3 In the Sn superconducting coil, the ou...

Embodiment 2

[0037] Preparation of stainless steel skeleton Nb 3 The Sn superconducting magnet solenoid coil, the preparation method and process parameters are the same as those in Example 1, except that the diameter of the spherical ceramic particles in the solidified filling material is 300 microns. the Nb 3 The Sn coil is placed in a 4.2K low temperature environment and the test shows that the Nb 3 Sn coils exhibit good low-temperature critical properties.

Embodiment 3

[0039] Preparation of stainless steel skeleton Nb 3 The Sn superconducting magnet solenoid coil, the preparation method and process parameters are basically the same as those in Example 1, except that the diameter of the spherical ceramic particles in the solidified filling material is 150 microns. the Nb 3 The Sn coil is placed in a 4.2K low temperature environment and the test shows that the Nb 3 Sn coils exhibit good low-temperature critical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com