Membrane system and treatment method for resource recovery and zero emission of manganese-containing wastewater and application of membrane system

A technology of resource recovery and zero discharge, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Utilize and unfavorable problems such as sustainable development of enterprises to achieve the effect of reducing operating costs and loss of manpower and material resources, realizing resource recovery and zero emissions, and improving filtering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

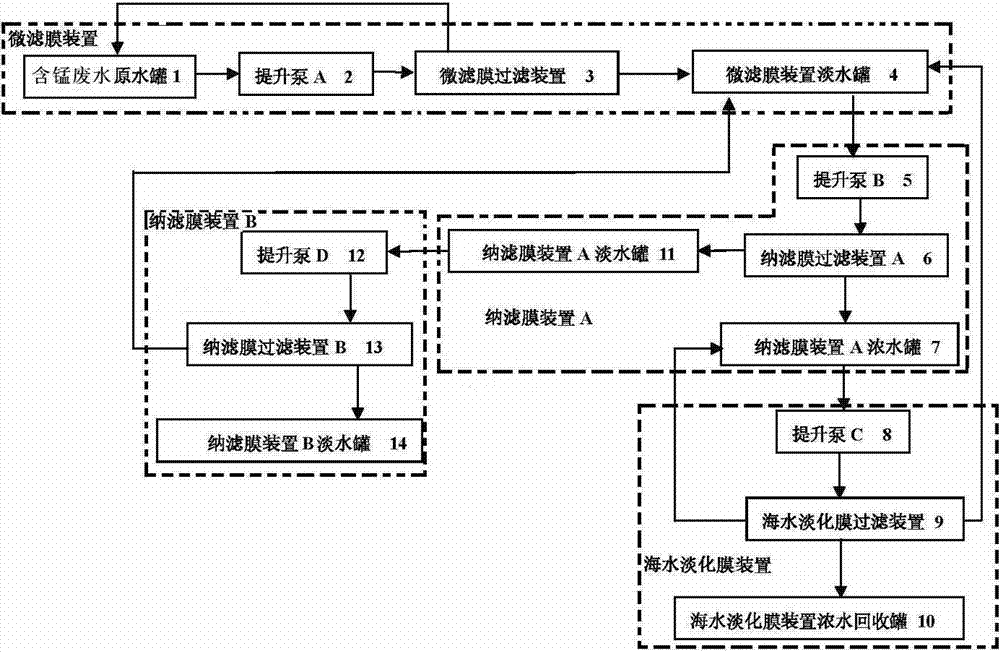

[0052] Such as figure 1 As shown, a manganese-containing wastewater resource recovery and zero-discharge membrane system includes a microfiltration membrane device, a nanofiltration membrane device A, a seawater desalination membrane device and a nanofiltration membrane device B; a microfiltration membrane device, a nanofiltration membrane device A and a Seawater desalination membrane devices are sequentially connected to form a circulation loop, and microfiltration membrane equipment, nanofiltration membrane equipment A and nanofiltration membrane equipment B are sequentially connected to form another circulation loop;

[0053] The microfiltration membrane device includes a manganese-containing wastewater raw water tank 1, a lifting pump A2, a microfiltration membrane filtration device 3, and a microfiltration membrane device concentrated water tank 4 connected in sequence, and the microfiltration membrane filtration device 3 is connected to the manganese-containing wastewater...

Embodiment 2

[0067] The manganese-containing wastewater resource recovery and zero-discharge membrane system of Example 1 was used to treat 16 batches of leachate raw water from the slag field, and the treatment method was as follows:

[0068](1) Store the leachate raw water in the slag field in the manganese-containing wastewater raw water tank to achieve uniform water quality;

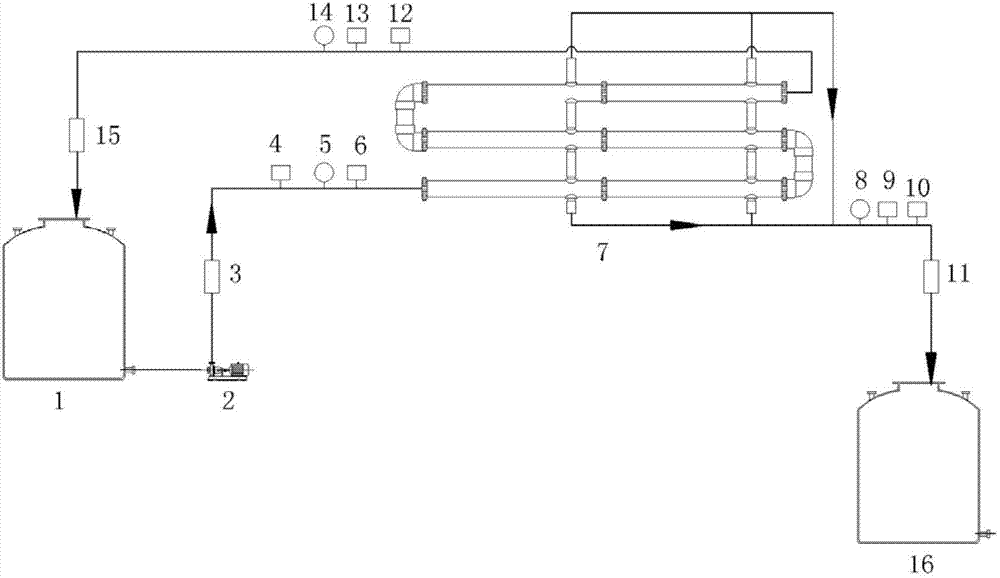

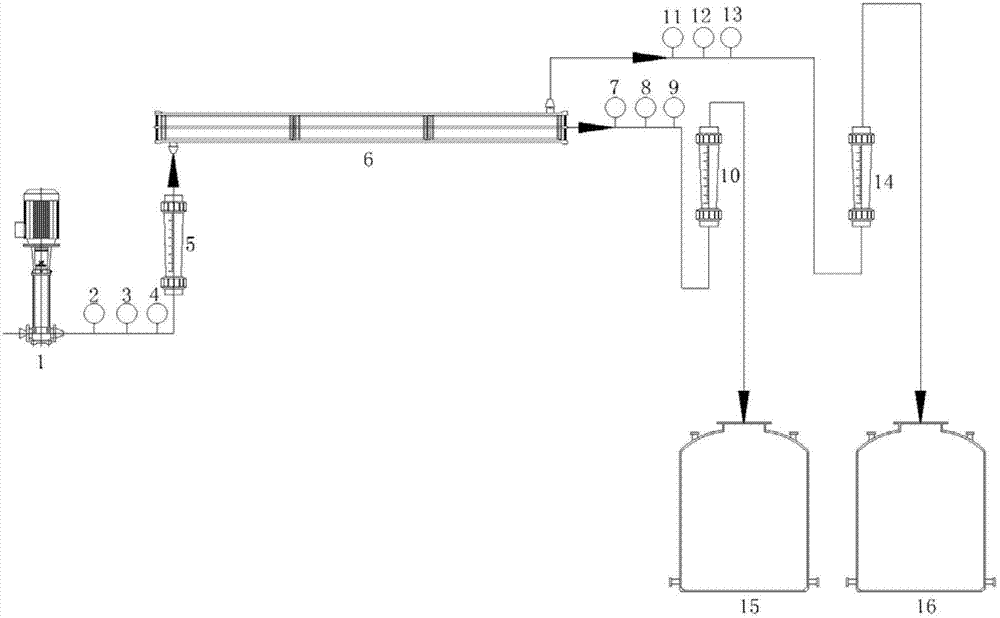

[0069] (2) Start the microfiltration membrane device: start the lift pump A, flow meter A (30-40m 3 / h), pressure gauge A (0.04~0.06Mpa), conductance online monitor A (8000~15000μs / cm), pressure gauge B (0~0.01Mpa), conductance online monitor B (8000~15000μs / cm), Flow meter B (3 ~ 4m 3 / h), conductance online monitor C (8000~15000μs / cm), pressure gauge C (0~0.03Mpa) and flowmeter C (20~35m 3 / h), the manganese-containing wastewater raw water enters the microfiltration membrane filtration device for cross-flow filtration to obtain fresh water A and concentrated water A; the concentrated water A returns to the ma...

Embodiment 3

[0078] The manganese-containing wastewater resource recovery and zero-discharge membrane system of Example 1 were used to treat 9 batches of manganese-containing comprehensive wastewater, and the treatment method was as follows:

[0079] (1) Store manganese-containing comprehensive wastewater in manganese-containing wastewater raw water tanks to achieve uniform water quality;

[0080] (2) Start the microfiltration membrane device: start the lift pump A, flow meter A (30-40m 3 / h), pressure gauge A (0.04~0.06Mpa), conductance online monitor A (8000~15000μs / cm), pressure gauge B (0~0.01Mpa), conductance online monitor B (8000~15000μs / cm), Flow meter B (3 ~ 4m 3 / h), conductance online monitor C (8000~15000μs / cm), pressure gauge C (0~0.03Mpa) and flowmeter C (20~35m 3 / h), so that the manganese-containing comprehensive wastewater enters the microfiltration membrane filtration device for cross-flow filtration to obtain fresh water A and concentrated water A; the concentrated wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com