Method for preparing graphene

A graphene and natural flake graphite technology, applied in the field of materials, can solve the problems of high manufacturing cost of graphene, low product quality, low productivity, etc., and achieve the effects of low production cost, low raw material cost, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

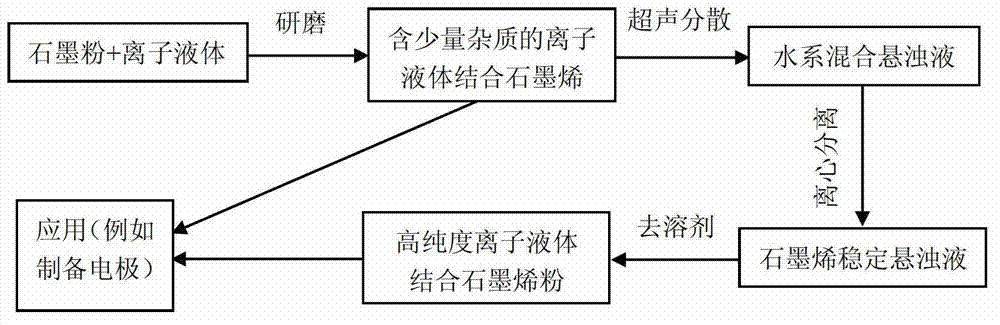

[0042] A method for preparing graphene, see the schematic diagram of the technical scheme figure 1 , Use natural flake graphite powder and N-octylpyridine hexafluorophosphate (OPFP) ionic liquid to mix, manually grind under anaerobic conditions, then disperse the resulting mixture in water, centrifuge to remove by-products, and volatilize the solvent (water), The graphene in the ionic liquid state is obtained. Specific steps are as follows:

[0043] Step 1: Mix natural flake graphite powder with a mass ratio of 1:0.6 and OPFP at room temperature.

[0044] Step 2: Put the mixture in an agate mortar and manually grind for 2 hours under nitrogen protection.

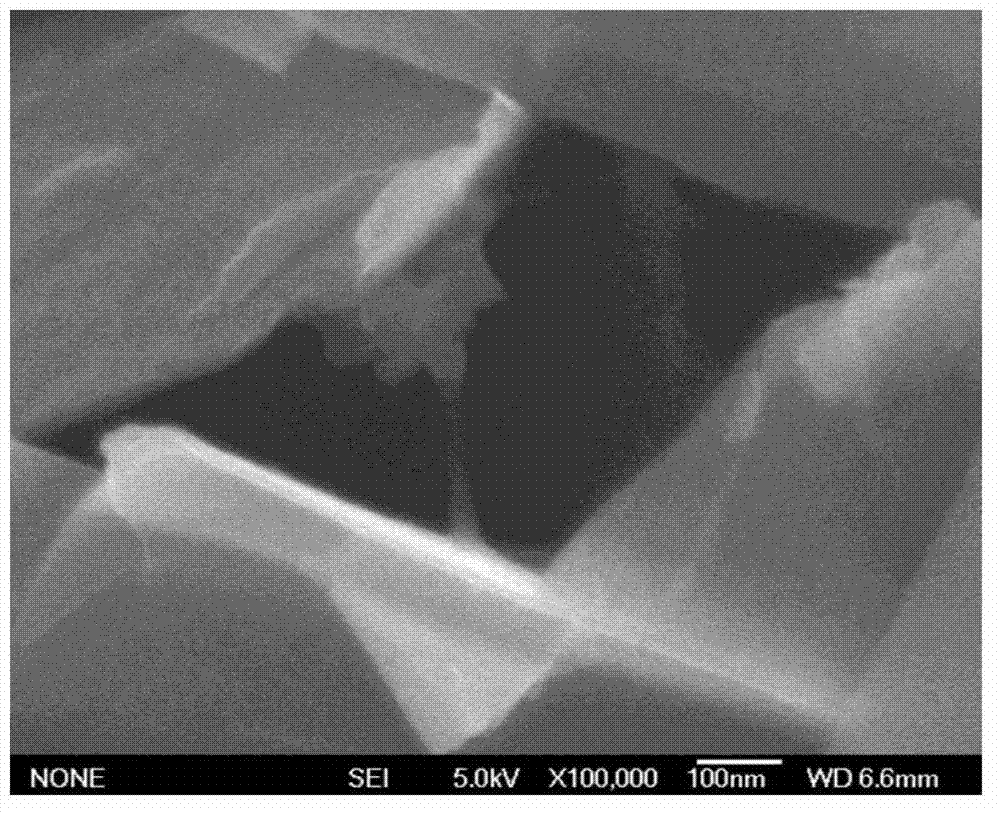

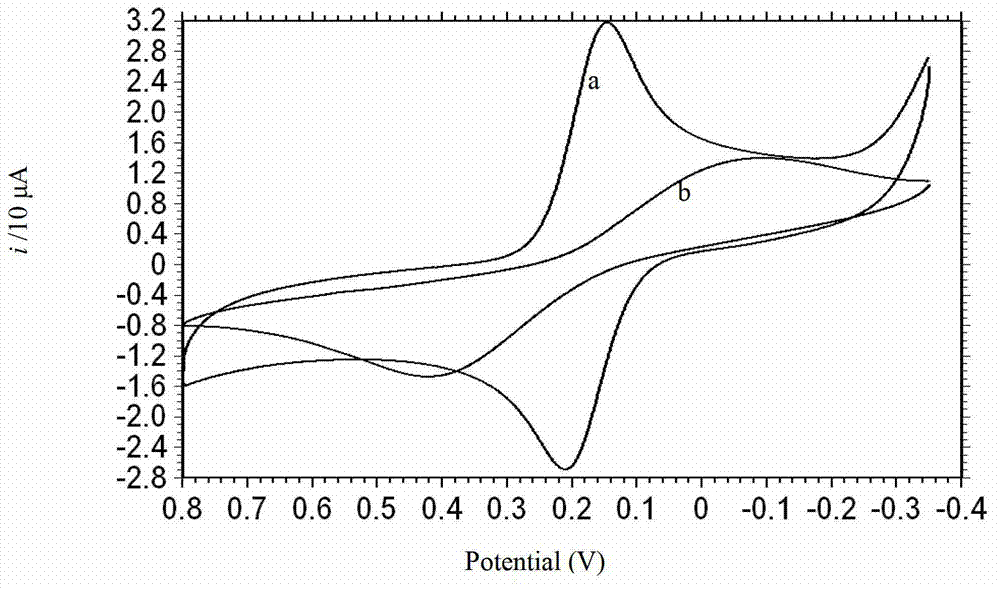

[0045] Step 3. The ionic liquid combined with graphene with a small amount of impurities after the grinding mixture can be directly used to prepare or modify electrochemical working electrodes, or it can be further processed to obtain high-purity OPFP combined with graphene—that is, 1g of the mixture is transferred into 0.5L of wa...

Embodiment 2

[0050] A method for preparing graphene, see the schematic diagram of the technical scheme figure 1 , Using natural flake graphite powder and N-hexylpyridine tetrafluoroborate ([Bpy]BF 4 ) Mix the ionic liquid, mechanically grind under anaerobic conditions, then disperse the resulting mixture in water, centrifuge to remove the by-products, and volatilize the solvent (water) to obtain graphene in the ionic liquid state. Specific steps are as follows:

[0051] Step 1: Combine natural flake graphite powder with a mass ratio of 1:2 and [Bpy]BF 4 Mix at room temperature.

[0052] Step 2: Put the mixture in a stainless steel tank, and under the protection of nitrogen, the stirrer drives a stainless steel ball with a diameter of 3 cm to stir and grind for 5 hours.

[0053] Step 3. The mixture after grinding is a small amount of impurity ionic liquid combined with graphene can be directly used to prepare or modify the electrochemical working electrode, or it can be further processed to obtain...

Embodiment 3

[0058] Using N-octylpyridine nitrate instead of N-octylpyridine hexafluorophosphate in Example 1, the other steps are the same as those in Example 1, and high-quality graphene can be prepared in the same way.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com