Al4SiC4 material synthetic method

A synthesis method and material technology, applied in the field of ceramic materials, can solve the problems of high cost of material technology and complex process, and achieve the effects of reducing production cost, simple process, and improving anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] a kind of Al 4 SiC 4 Synthesis method of materials. 55% of Al powder, 25% of SiC powder, and 20% of carbon black are weighed and proportioned according to mass percentage, and absolute ethanol is added until the material is submerged, fully mixed evenly on a planetary mill, and the obtained mixture is in Dry at 80°C. Compress the obtained mixture under a pressure of 300MPa, then bury the sample in a graphite crucible filled with metal aluminum powder, then put the graphite crucible into the furnace, heat it at 1600°C and keep it warm for 3 hours under the condition of carbon embedding. After cooling, take out the sample from the graphite crucible and remove the impurity layer on the surface to obtain Al 4 SiC 4 Material.

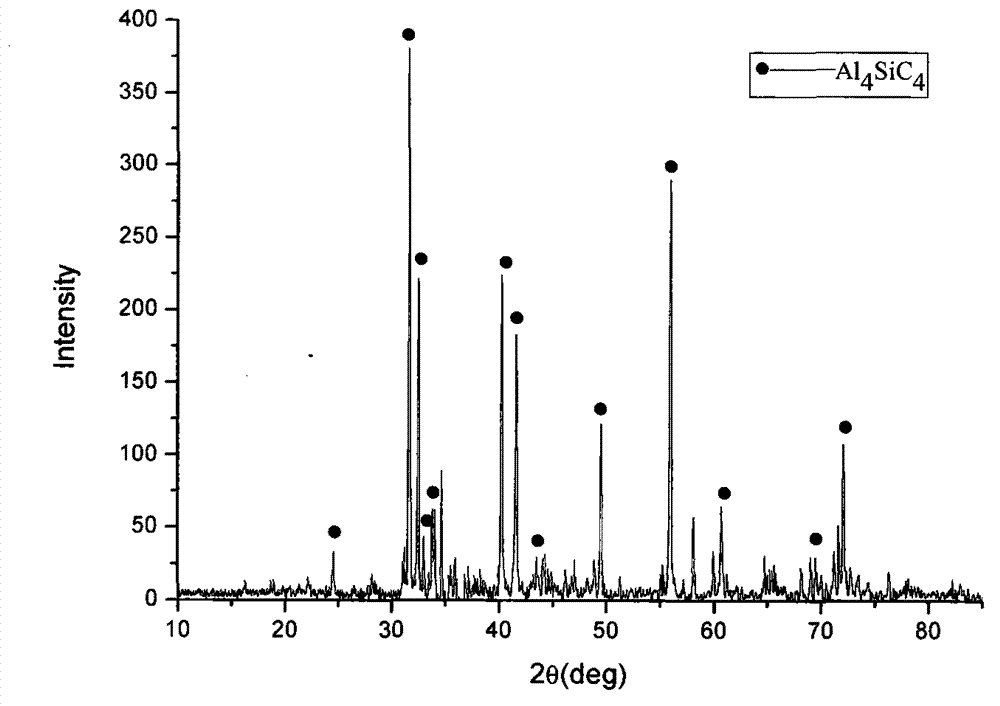

[0017] from figure 1 It can be seen that the phase of the synthesized material of the present invention is Al 4 SiC 4 .

Embodiment 2

[0019] a kind of Al 4 SiC 4 Synthesis method of materials. 65% of Al powder, 20% of SiC powder, and 15% of graphite are weighed and proportioned according to the mass percentage content, and absolute ethanol is added until the material is submerged, and the mixture is fully mixed evenly on the planetary mill, and the obtained mixture is at 80 ℃ drying. Compress the obtained mixture under a pressure of 250MPa, then bury the sample in a graphite crucible filled with metal aluminum powder, then put the graphite crucible into the furnace, heat it at 1650°C and keep it warm for 4 hours under the condition of carbon embedding. After cooling, take out the sample from the graphite crucible and remove the impurity layer on the surface to obtain Al 4 SiC 4 Material.

Embodiment 3

[0021] a kind of Al 4 SiC 4 Synthesis method of materials. 61% of Al powder, 22% of SiC powder, and 17% of graphite are weighed and proportioned according to the mass percentage content, and absolute ethanol is added until the material is submerged, and the mixture is fully mixed on the planetary mill, and the obtained mixture is at 80 ℃ drying. Add 3% phenolic resin of the weight of the mixture into the dried mixture as a binder, and press it under a pressure of 220MPa. After the product is treated at 240°C, the sample is buried in a graphite crucible containing metal aluminum powder. , and then put the graphite crucible into the furnace under the condition of burying carbon, heat it at 1600°C and keep it warm for 3 hours. After cooling, take the sample out of the graphite crucible and remove the impurity layer on the surface to obtain Al 4 SiC 4 Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com