Purification method for strontium carbonate

A purification method and technology of strontium carbonate, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of low purity of strontium carbonate, serious agglomeration, unfavorable dispersion, etc., achieve high crystallinity, narrow particle size distribution, convenient production and processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

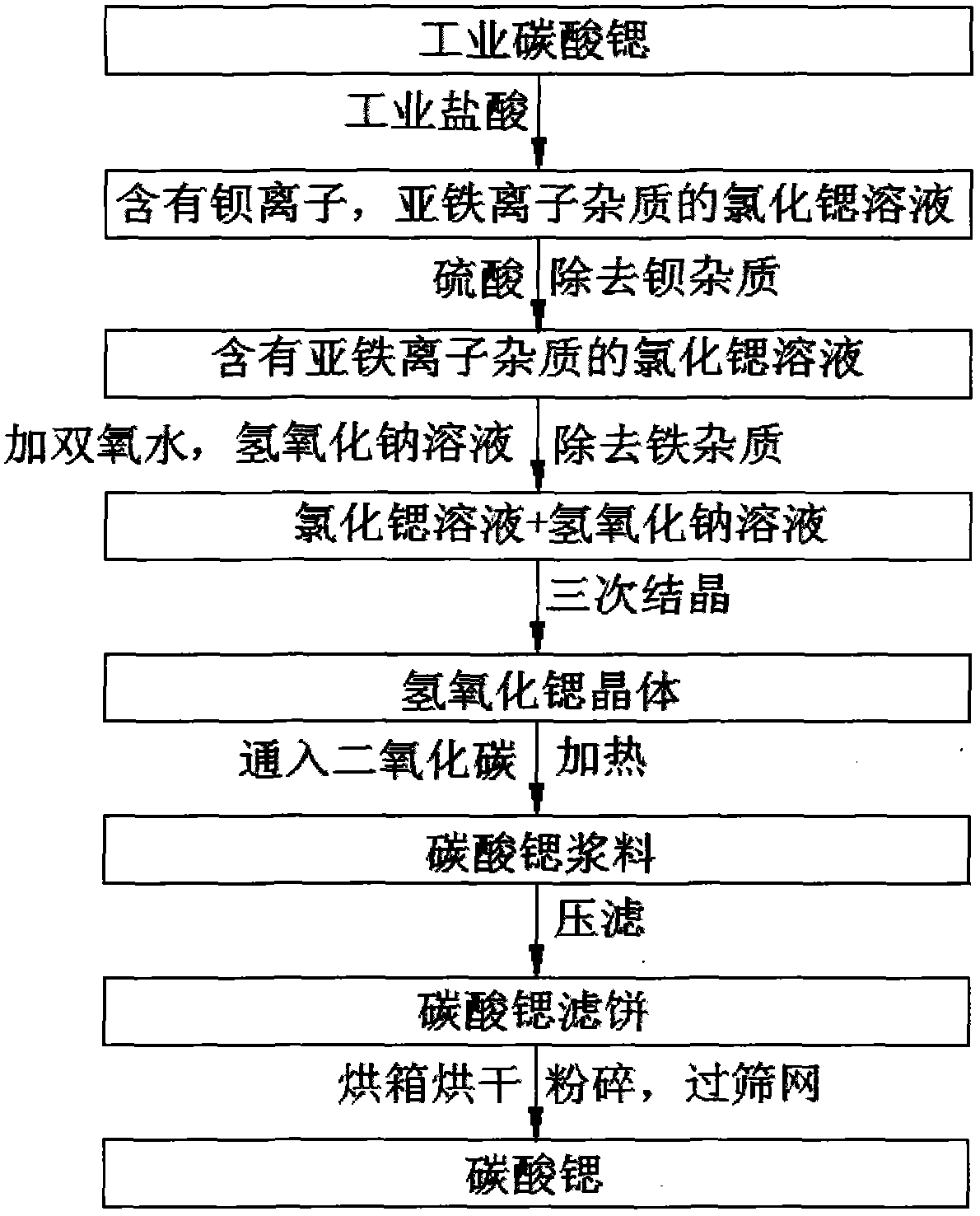

[0025] A kind of purification method of strontium carbonate of embodiment 1, comprises the following steps:

[0026] Step 1. Using industrial strontium carbonate as raw material, removing barium and iron impurities therein, removing slag by pressure filtration to obtain a strontium chloride solution. Its concrete process steps are as follows:

[0027] A. remove barium impurity: industrial strontium carbonate (purity is about 95%) is dissolved with industrial hydrochloric acid, add the sulfuric acid (H 2 SO 4 ), remove the barium impurity, and the acidic solution containing chlorine elements includes industrial hydrochloric acid and hypochlorous acid etc., preferred industrial hydrochloric acid;

[0028] B. remove iron impurity: adding weight ratio is about 6%-10% hydrogen peroxide (H 2 o 2 ), boil for 15-60 minutes, add liquid sodium hydroxide solution (NaOH) to adjust the pH value to 7.0-7.5 to remove iron impurities, the oxidant includes hydrogen peroxide and sodium pero...

Embodiment 2

[0036] A kind of purification method of strontium carbonate of embodiment 2, comprises the following steps:

[0037] Step 1. Using industrial strontium carbonate as raw material, removing barium and iron impurities therein, removing slag by pressure filtration to obtain a strontium chloride solution. Its concrete process steps are as follows:

[0038] A. remove barium impurity: industrial strontium carbonate (purity is about 95%) is dissolved with industrial hydrochloric acid, add the sulfuric acid (H 2 SO 4 ), remove the barium impurity, and the acidic solution containing chlorine elements includes industrial hydrochloric acid and hypochlorous acid etc., preferred industrial hydrochloric acid;

[0039] B. remove iron impurity: adding weight ratio is about 6%-10% hydrogen peroxide (H 2 o 2 ), boil for 15-60 minutes, add liquid sodium hydroxide solution (NaOH) to adjust the pH value to 7.0-7.5 to remove iron impurities, the oxidant includes hydrogen peroxide and sodium pero...

Embodiment 3

[0047] A kind of purification method of strontium carbonate of embodiment 3 comprises the following steps:

[0048] Step 1. Using industrial strontium carbonate as raw material, removing barium and iron impurities therein, removing slag by pressure filtration to obtain a strontium chloride solution. Its concrete process steps are as follows:

[0049] A. remove barium impurity: industrial strontium carbonate (purity is about 95%) is dissolved with industrial hydrochloric acid, add the sulfuric acid (H 2 SO 4 ), remove the barium impurity, and the acidic solution containing chlorine elements includes industrial hydrochloric acid and hypochlorous acid etc., preferred industrial hydrochloric acid;

[0050] B. remove iron impurity: adding weight ratio is about 6%-10% hydrogen peroxide (H 2 o 2 ), boil for 15-60 minutes, add liquid sodium hydroxide solution (NaOH) to adjust the pH value to 7.0-7.5 to remove iron impurities, the oxidant includes hydrogen peroxide and sodium perox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com