Method for preparing cubic crystal system cerium oxide nanocrystal

A technology of cubic crystal system and cerium oxide, which is applied in the direction of chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of uniform mixing, inferior raw materials, and long time required to achieve high sample purity, similar shape, even size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

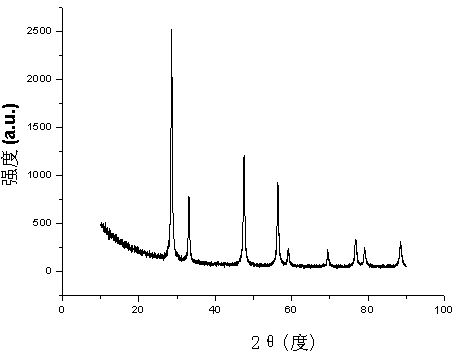

Image

Examples

Embodiment 1

[0027] (1) Weigh 0.5g of gelatin and dissolve it in 49.5g of hot water at 70°C to prepare an aqueous solution of gelatin with a mass fraction of 1%;

[0028] (2) Weigh 2.1711g Ce(NO 3 ) 3 ?6H 2 O is dissolved in the aqueous gelatin solution to prepare a 0.1mol / L cerous nitrate solution;

[0029] (3) Weigh 1.6987g of hydrogen peroxide solution with a mass fraction of 30% (containing H 2 o 2 0.5096g, combined 0.015mol), add in the cerous nitrate solution, stir, until the flocculent insoluble matter is formed in the liquid, obtain the solution containing the flocculent insoluble matter; The ratio of the amount of the cerous nitrate to the hydrogen peroxide substance is 1:3.

[0030] (4) dripping ammonia water with a mass concentration of 28% into the solution containing flocculent insolubles described in step (3), until the pH of the solution is 10, forming a large amount of insolubles;

[0031] (5) Collecting a large amount of insoluble matter described in step (4) by fil...

Embodiment 2

[0036] (1) Weigh 1.0g of gelatin and dissolve it in 49.0g of hot water at 70°C to prepare an aqueous gelatin solution with a mass fraction of 2%;

[0037] (2) Weigh 2.1711g Ce(NO 3 ) 3 ?6H 2 O is dissolved in the aqueous gelatin solution to prepare a 0.1mol / L cerous nitrate solution;

[0038] (3) Weigh 1.6987g of hydrogen peroxide solution with a mass fraction of 30% (containing H 2 o 2 0.5096g, combined 0.015mol), add in the cerous nitrate solution, stir, until the flocculent insoluble matter is formed in the liquid, obtain the solution containing the flocculent insoluble matter; The ratio of the amount of the cerous nitrate to the hydrogen peroxide substance is 1:3.

[0039] (4) dripping ammonia water with a mass concentration of 28% into the solution containing flocculent insolubles described in step (3), until the pH of the solution is 10, forming a large amount of insolubles;

[0040] (5) Collecting a large amount of insoluble matter described in step (4) by filtra...

Embodiment 3

[0044] (1) Weigh 2.5g of gelatin and dissolve it in 47.5g of hot water at 70°C to prepare an aqueous gelatin solution with a mass fraction of 5%;

[0045] (2) Weigh 2.1711g Ce(NO 3 ) 3 ?6H 2 O is dissolved in the aqueous gelatin solution to prepare a 0.1mol / L cerous nitrate solution;

[0046] (3) Weigh 1.6987g of hydrogen peroxide solution with a mass fraction of 30% (containing H 2 o 2 0.5096g, combined 0.015mol), add in the cerous nitrate solution, stir, until the flocculent insoluble matter is formed in the liquid, obtain the solution containing the flocculent insoluble matter; The ratio of the amount of the cerous nitrate to the hydrogen peroxide substance is 1:3.

[0047] (4) dripping ammonia water with a mass concentration of 28% into the solution containing flocculent insolubles described in step (3), until the pH of the solution is 10, forming a large amount of insolubles;

[0048] (5) Collecting a large amount of insoluble matter described in step (4) by filtrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com