River way water purification and water resource supply system as well as working method thereof

A working method and water purification technology, applied in the field of water pollution control, can solve the problems of unstable treatment effect, high mud production, large dosage of medicine, etc., and achieve the effects of stable treatment effect, high quality of effluent, and low dosage of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

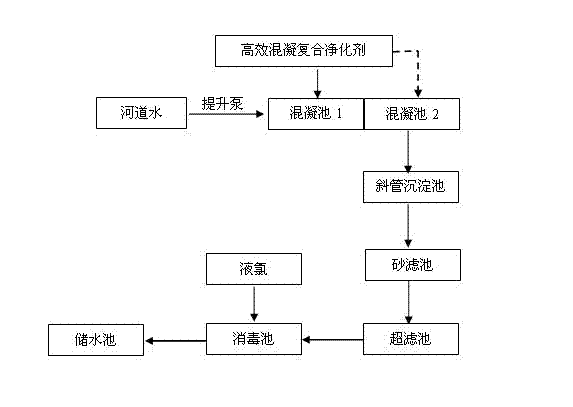

[0022] (1) Coagulation reaction unit

[0023] The river water is lifted to the first coagulation tank through the lifting pump, and at the same time, 2-5mg / L composite natural inorganic polymer water purifier is added by dry powder dosing method. The water purifier is mainly composed of polyaluminum chloride compounded with micron-sized natural ore powder, and compounded with 5% diatomaceous earth and 10-15% polyferric sulfate. The dry powder dosing method is used for coagulation at this stage. The coagulation stirring speed is required to reach 120-150 rpm. Stage stay 30-60s;

[0024] Self-flow into the second coagulation tank for coagulation, where secondary coagulation is carried out. Generally, there is no need to add high-efficiency coagulation composite water purifier at this stage. According to actual conditions, an appropriate amount of high-efficiency coagulation composite water purifier can also be added at this time. Water agent, while controlling the stirring spe...

Embodiment 2

[0046] (1) Coagulation reaction unit

[0047] The river water is lifted to the first coagulation tank through the lifting pump, and at the same time, 2-5mg / L composite natural inorganic polymer water purifying agent is added by dry powder dosing method. Coagulation is carried out at this stage, and the coagulation stirring speed is required to reach 130 rpm min, stay at this stage for 45s;

[0048] Self-flow into the second coagulation tank for coagulation, and then carry out secondary coagulation. Generally, it is not necessary to add high-efficiency coagulation composite water purifier at this stage. According to actual conditions, an appropriate amount of high-efficiency coagulation composite water purifier can also be added at this time. Water agent, while performing secondary discharge. Control the stirring speed at 90 rpm, and the residence time here is 90s to form large flocs;

[0049]The high-efficiency coagulation compound water purifier is a natural inorganic poly...

Embodiment 3

[0070] (1) Coagulation reaction unit

[0071] The river water is lifted to the first coagulation tank through the lifting pump, and at the same time, 2-5 mg / L composite natural inorganic polymer water purifying agent is added by dry powder dosing method. Coagulation is carried out at this stage, and the coagulation stirring speed is required to reach 140 rpm min, stay at this stage for 60s;

[0072] Self-flow into the second coagulation tank for coagulation, and then carry out secondary coagulation. Generally, it is not necessary to add high-efficiency coagulation composite water purifier at this stage. According to actual conditions, an appropriate amount of high-efficiency coagulation composite water purifier can also be added at this time. Water agent, while performing secondary discharge. Control the stirring speed at 100 rpm, and the residence time here is 120s to form large flocs;

[0073] The high-efficiency coagulation compound water purifier is a natural inorganic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com