Method for treating light hydrocarbon-containing petrochemical gas

A petrochemical and processing method technology, which is applied to the processing field of petrochemical gas containing light hydrocarbons, can solve the problems such as the ineffective utilization of C2 light hydrocarbons, and achieves good recovery effect and significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

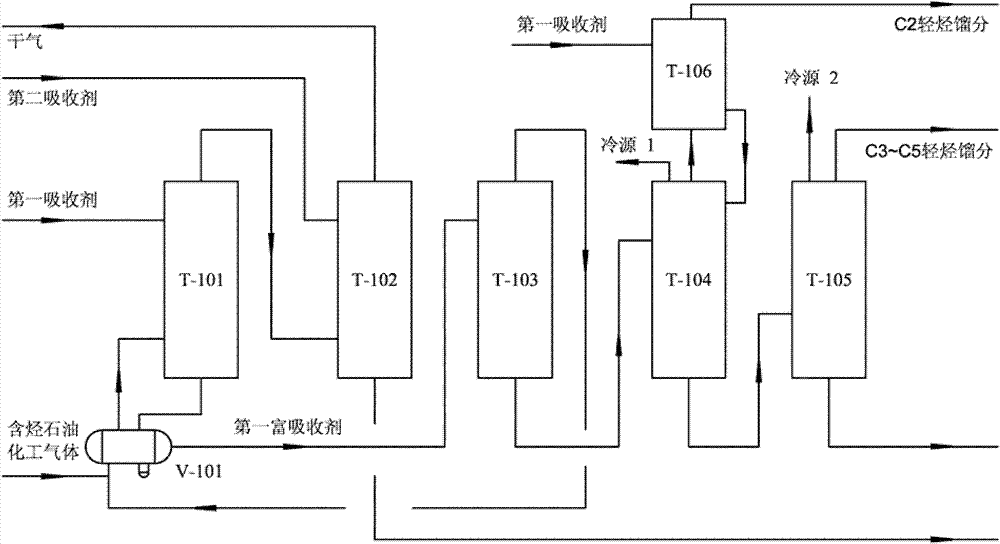

Method used

Image

Examples

Embodiment 1

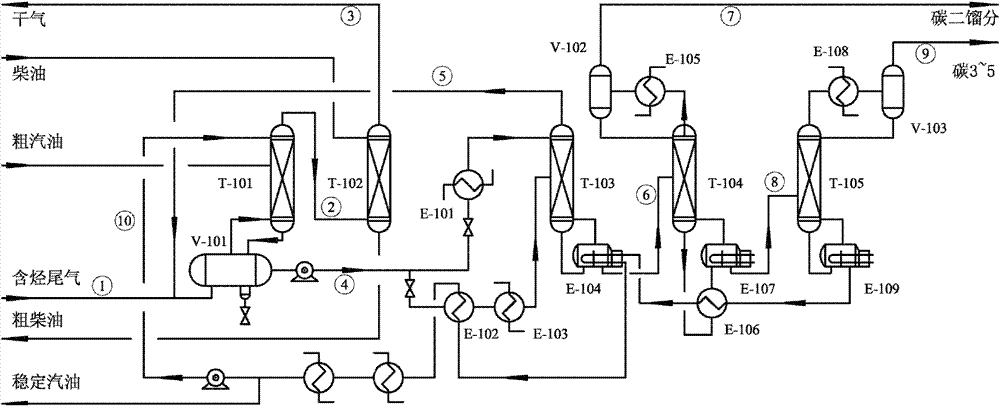

[0047] This embodiment is used to illustrate the treatment method for petrochemical gas containing light hydrocarbons provided by the present invention.

[0048] This example uses figure 2 The process flow shown. Such as figure 2As shown, (1) After the compressed hydrocarbon-containing tail gas ① is contacted with the first rich absorption liquid from the bottom of the first absorption tower T-101 in the absorption balance tank V-101 for gas-liquid phase separation, the gas phase enters the first At the bottom of the absorption tower T-101, conduct reverse contact mass transfer with the first absorbent naphtha entering from the top of the T-101 tower to obtain the first rich absorption liquid ④ and the first lean gas ②, and transfer them from the bottom and top of the tower respectively Discharge; (2) The first lean gas from the top of the first absorption tower T-101 ② enters from the bottom of the second absorption tower T-102, and the second absorbent diesel enters from...

Embodiment 2

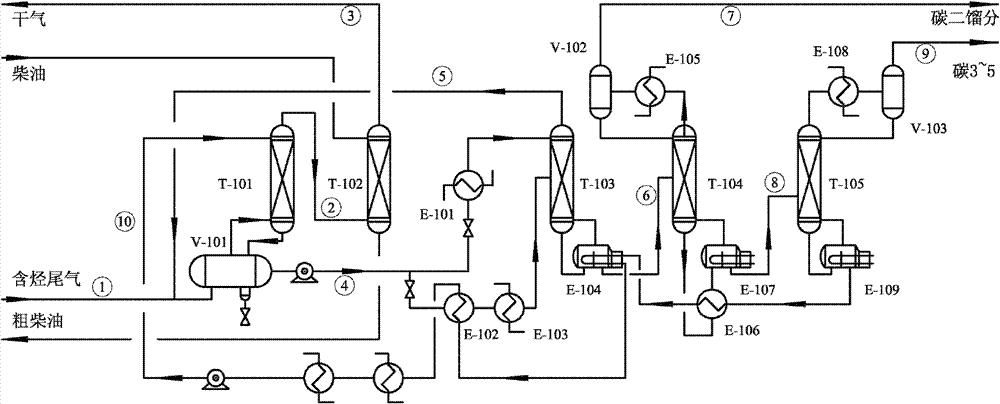

[0051] This embodiment is used to illustrate the treatment method for petrochemical gas containing light hydrocarbons provided by the present invention.

[0052] According to the method of embodiment 1, the petrochemical gas containing light hydrocarbons is processed, and the difference is that the image 3 process flow. image 3 process flow and figure 2 Similar, but the difference is that all the stabilized gasoline from the rectification tower T-105 is used as the first absorbent, and the stable gasoline product is not discharged, and the gas oil is no longer used as the first absorbent after the stable operation.

[0053] Wherein the hydrocarbon-containing tail gas is coking dry gas (the composition is shown in the stream ① in Table 5), the raw material addition rate is 9.75 tons / hour, diesel oil is used as the second absorbent, and the volume ratio of the first absorbent to coking dry gas is 1:3.9 , the consumption of the second absorbent is 12 tons / hour, and the opera...

Embodiment 3

[0055] This embodiment is used to illustrate the treatment method for petrochemical gas containing light hydrocarbons provided by the present invention.

[0056] According to the method of embodiment 2, the petrochemical gas containing light hydrocarbons is processed, and the difference is that the tail gas containing hydrocarbons is a catalytic cracking gas (the composition is shown in Table 6, logistics ①), and the raw material addition is 15.93 tons / hour, taking stable gasoline as The first absorbent, with diesel oil as the second absorbent, the volume ratio of the first absorbent to catalytic cracking gas is 1: 5.2, and the consumption of the second absorbent is 13 tons / hour. The operating parameters in the tower are shown in Table 2. The composition and operating parameters of key logistics streams are shown in Table 6, and the consumption of heat source and cold source is shown in Table 3. Output: carbon two components 2.61t / h; liquefied petroleum gas 8.98t / h, the recove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com