Method for preparing medium-purity terephthalic acid by gradual heating oxidation

A terephthalic acid, step-by-step heating technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc. problems, to achieve the effect of eliminating the hydrorefining process, reducing the consumption of combustion side reactions, and promoting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

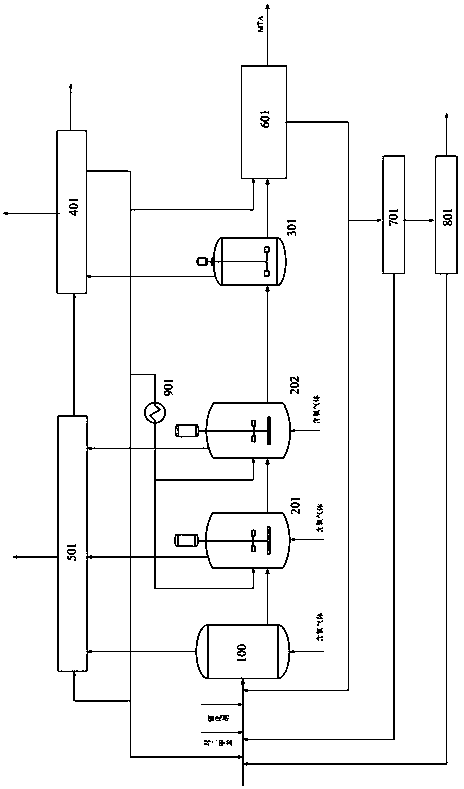

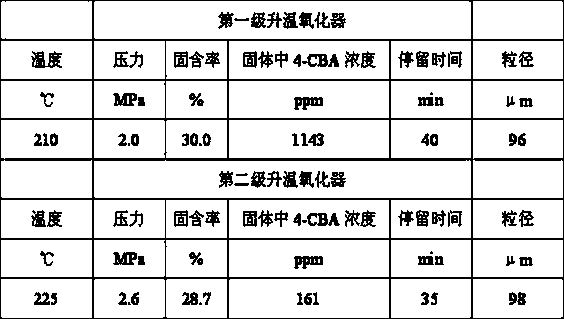

[0028] Medium-purity terephthalic acid production is carried out according to the method given by the present invention, according to figure 1 The relevant process parameters, results and related indicators of each unit are introduced in the sequence of the flow process, and the related process parameters, results and related indicators obtained are as follows:

[0029] 1. Main oxidation reaction unit

[0030] Table 1 Process conditions of the main oxidation reactor

[0031] temperature pressure PX processing capacity Catalyst concentration / ppm ℃ MPa t / h Co / Mn / Br 190 1.20 48.36 600 / 640 / 900 Feed HAC / PX air velocity Condensate Reflux Temperature dwell time mass ratio (kg / s) ℃ min 4.90 64 161 64

[0032] Table 2 Output indicators of the main oxidation reactor

[0033] PX conversion rate TA yield Solid holdup 4-CBA concentration in mother liquor Water content of mother liquor % % % ppm % ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com