Ingot thermal field for growing pure quasi-monocrystalline

A quasi-single crystal and ingot casting technology, which is applied in the field of ingot thermal field, can solve the problems that the formation and growth of new crystal nuclei cannot be completely inhibited, the quality of the crystal is unfavorable, and the crystal structure is destroyed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

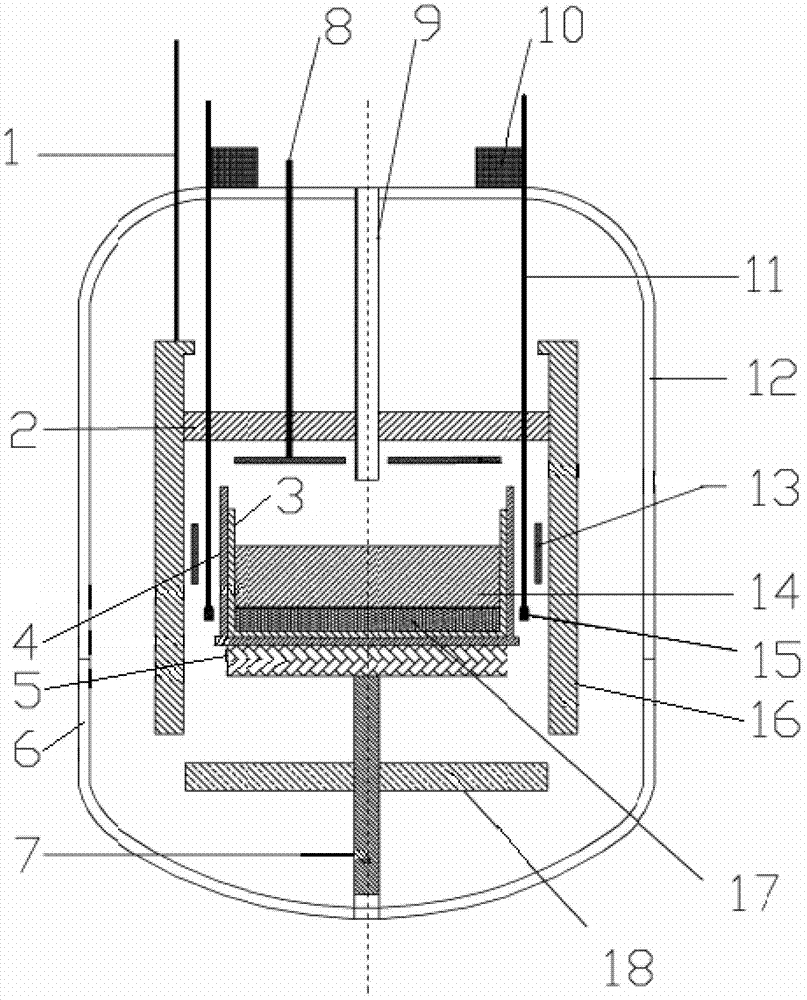

[0016] The present invention will be further described now in conjunction with accompanying drawing. These drawings are simplified schematic diagrams only to illustrate the basic structure of the present invention in a schematic way, so they only show the components relevant to the present invention.

[0017] Such as figure 1 As shown, an ingot thermal field for growing a pure quasi-single crystal has an upper furnace body 12 and a lower furnace body 6, and a quartz ceramic crucible 3 is arranged in the cavity formed by the upper furnace body 12 and the lower furnace body 6, and the quartz ceramic crucible is The crucible 3 is placed in the graphite crucible 4, the bottom of the graphite crucible 4 is provided with a graphite coagulation aid 5, and the graphite aid coagulation 5 is supported by a support column 7, a silicon solution 14 is added in the quartz ceramic crucible 3, and the bottom of the silicon solution 14 is in the crystal growth area. Silicon crystals 17 are fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com