Numerical control machine tool thermal error real-time compensation modeling method based on time series algorithm

A technology of numerical control machine tools and time series, applied in the direction of program control, computer control, simulators, etc., can solve the problems that the mathematical model cannot achieve the compensation effect, it is difficult to guarantee the accuracy of the model, and the processing accuracy is difficult to guarantee, so as to improve the modeling accuracy and practicality, reducing complexity, and reducing hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] Embodiments of the present invention will be described below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the invention, and detailed implementation methods and specific processes are given, but the protection scope of the present invention is not limited to the following embodiments.

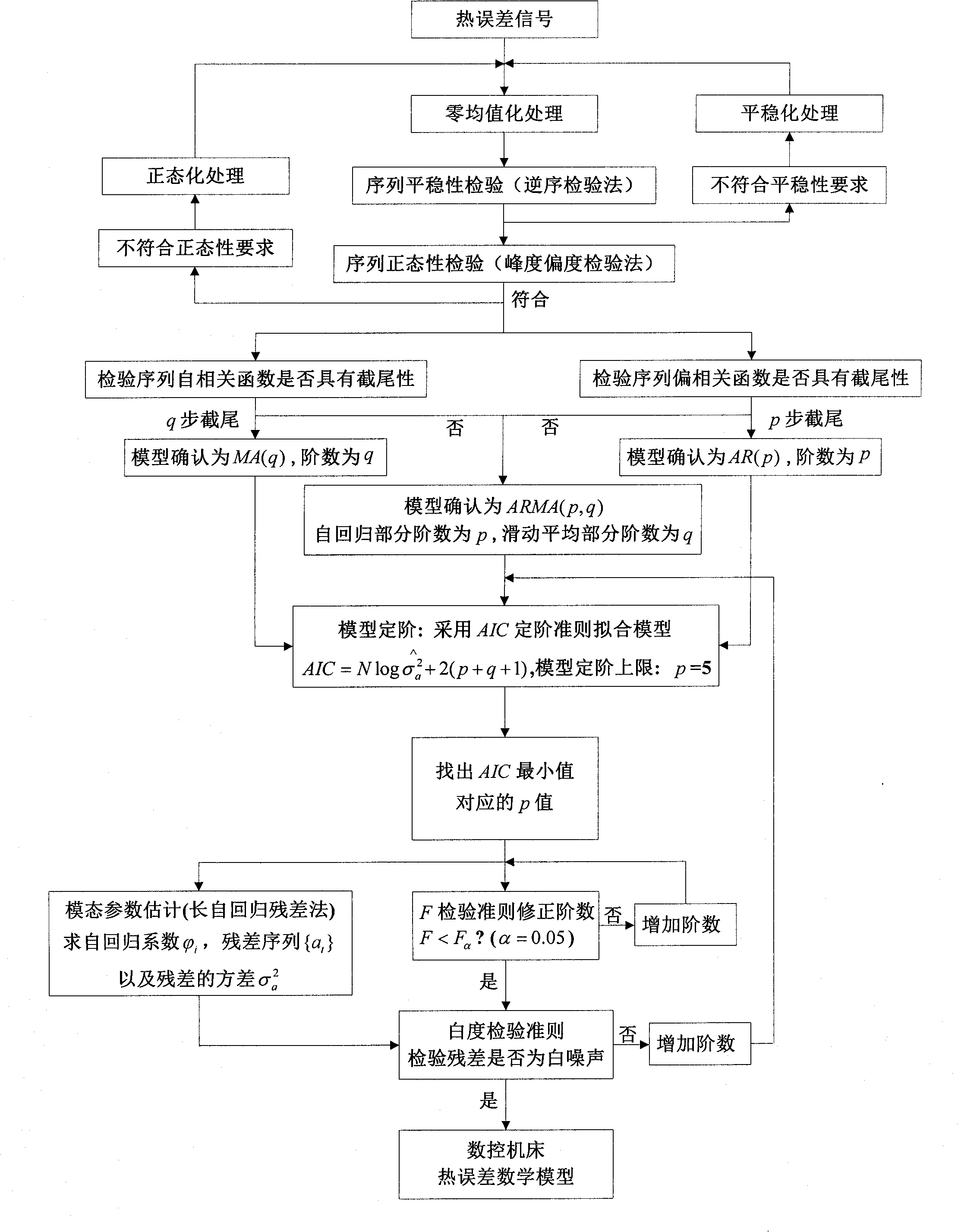

[0084] The thermal error real-time modeling method described in the present invention is a reasoning method based on a time series algorithm, and the specific implementation process is as follows:

[0085] Modeling and analysis of the thermal error compensation model for the spindle of a turning machining center, the thermal error data of the spindle in the X and Z directions are measured by two eddy current displacement sensors fixed on the tool holder, and the data is automatically collected by the platform at 10Hz The sampling rate automatically records thermal drift error values in both directions. The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com