Multi-layer metal ohmic contact system adopting silicon alloys and manufacturing method thereof

A technology of ohmic contact and multi-layer metal, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of device performance degradation, reduce ohmic contact resistance, and the influence of crystal quality of epitaxial materials, etc., to achieve small contact resistance, Control repeatability, good repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

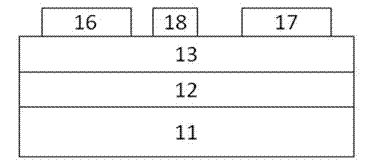

[0034] Embodiment 1, in conjunction with Fig. 2, Figure 5 ,

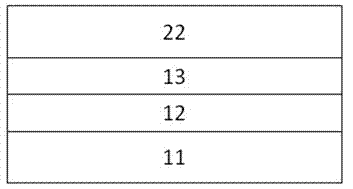

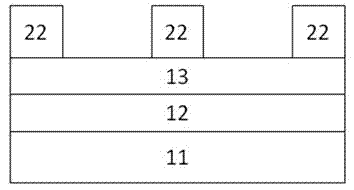

[0035] first as Figure 2A As shown, a photoresist layer 22 is coated on the AlGaN barrier layer 13, and then exposed and developed to form a Figure 2B The graph shown, again as Figure 2C The first ohmic contact metal layer 21 is shown on the AlGaN barrier layer 13 and the photoresist layer 22, and finally the photoresist layer 22 and the first ohmic contact metal layer 21 thereon are removed through stripping to obtain the following Figure 2D Source electrode 16 and drain electrode 17 are shown.

[0036] Wherein the first ohmic contact metal layer 21 such as Figure 5 As shown, it consists of four metal layers, starting from the interface between the AlGaN layer 13 and the first ohmic contact metal layer 21, the first TiSi alloy metal layer 51, the Al metal layer 52, the first barrier metal layer 53 and the first Au The metal layer 54 is composed. The thickness of the first TiSi alloy metal layer 51 is 15...

Embodiment 2

[0039] Embodiment 2, contrast image 3 , combined with Figure 2, Image 6 ,

[0040] first as Figure 2A As shown, a photoresist layer 22 is coated on the AlGaN barrier layer 13, and then exposed and developed to form a Figure 2B The graph shown, again as image 3 The second ohmic contact metal layer 31 is shown on the AlGaN barrier layer 13 and the photoresist layer 22, and finally the photoresist layer 22 and the second ohmic contact metal layer 31 thereon are removed through stripping to obtain the following Figure 2D Source electrode 16 and drain electrode 17 are shown.

[0041] The second ohmic contact metal layer 31 such as Image 6 As shown, it consists of four metal layers, starting from the interface of the AlGaN layer 13 and the second ohmic contact metal layer 31, sequentially consisting of a Ti metal layer 61, a first AlSi alloy metal layer 62, a second barrier metal layer 63 and a second Au metal layer. Metal layer 64, wherein the thickness of Ti metal lay...

Embodiment 3

[0044] Example 3, contrast Figure 4 , combined with Figure 2, Figure 7 ,

[0045] first as Figure 2A As shown, a photoresist layer 22 is coated on the AlGaN barrier layer 13, and then exposed and developed to form a Figure 2B The graph shown, again as Figure 4 The third ohmic contact metal layer 41 shown is on the AlGaN barrier layer 13 and the photoresist layer 22, and finally the photoresist layer 22 and the third ohmic contact metal layer 41 thereon are removed through stripping to obtain the following Figure 2D Source electrode 16 and drain electrode 17 are shown.

[0046] Wherein the third ohmic contact metal layer 41 such as Figure 7 As shown, it consists of four metal layers, starting from the interface of the AlGaN layer 13 and the third ohmic contact metal layer 41, the second TiSi alloy metal layer 71, the second AlSi alloy metal layer 72, the third barrier metal layer 73 and The third Au metal layer 74 is composed. The thickness of the second TiSi allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com