Blue-ray fluorescent organic light emitting diode and manufacturing method thereof

A light-emitting diode and blue light technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of device operating voltage increase and power efficiency decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a preparation method of a blue-light fluorescent organic light-emitting diode, the steps are as follows:

[0043] Carve the anode indium tin oxide into a thin strip electrode on a glass or flexible polymer substrate, then clean it, dry it with nitrogen, treat it with plasma for 1-5min, and bake it in a vacuum oven at 120°C for 30min-60min , and then transfer it to the vacuum coating system until the vacuum degree reaches 1 to 5×10 -4 At Pascal, the hole injection layer, the p-doped hole transport layer, the hole transport layer, the light-emitting layer, the electron transport / hole blocking layer, the n-doped electron transport layer, the electron injection layer and the cathode layer were evaporated in sequence, two of which The intersecting parts of the two electrodes form the light-emitting area of the blue-light fluorescent organic light-emitting diode. The area of the light-emitting area is 16 square millimeters. The thicknes...

Embodiment 1

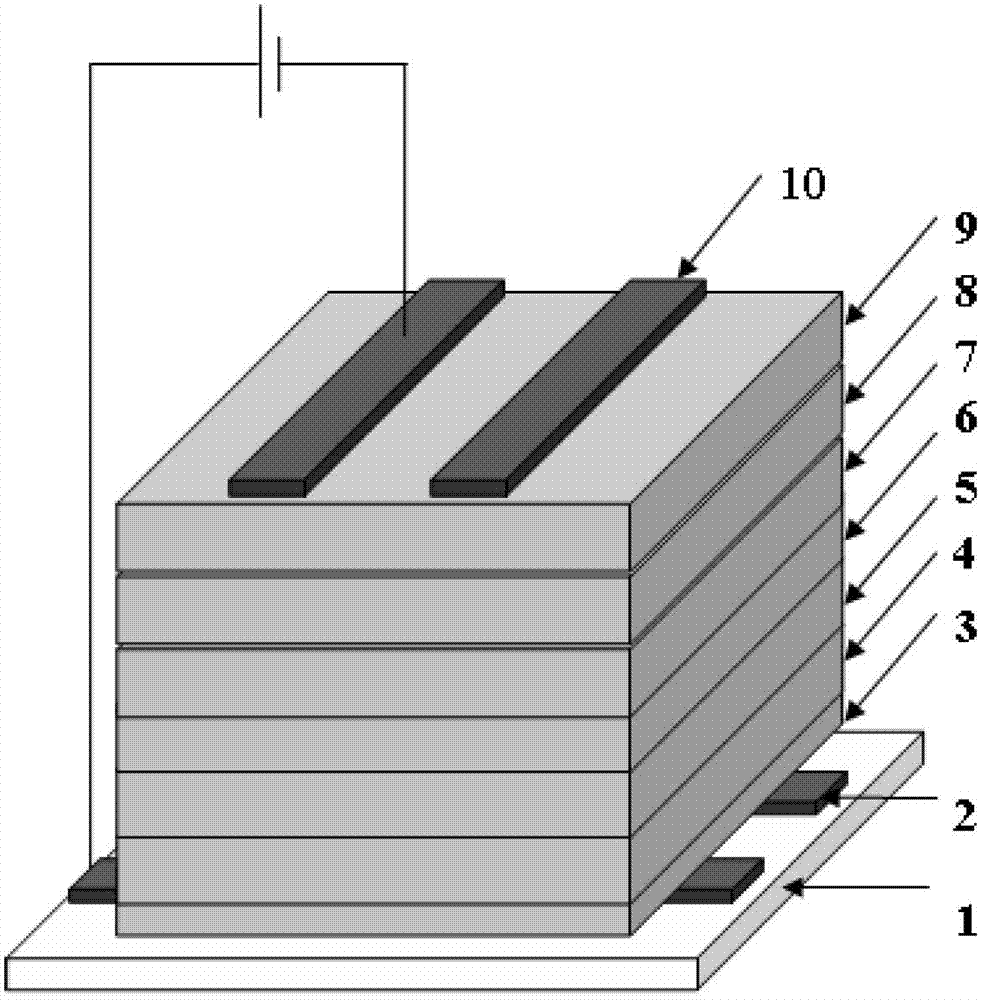

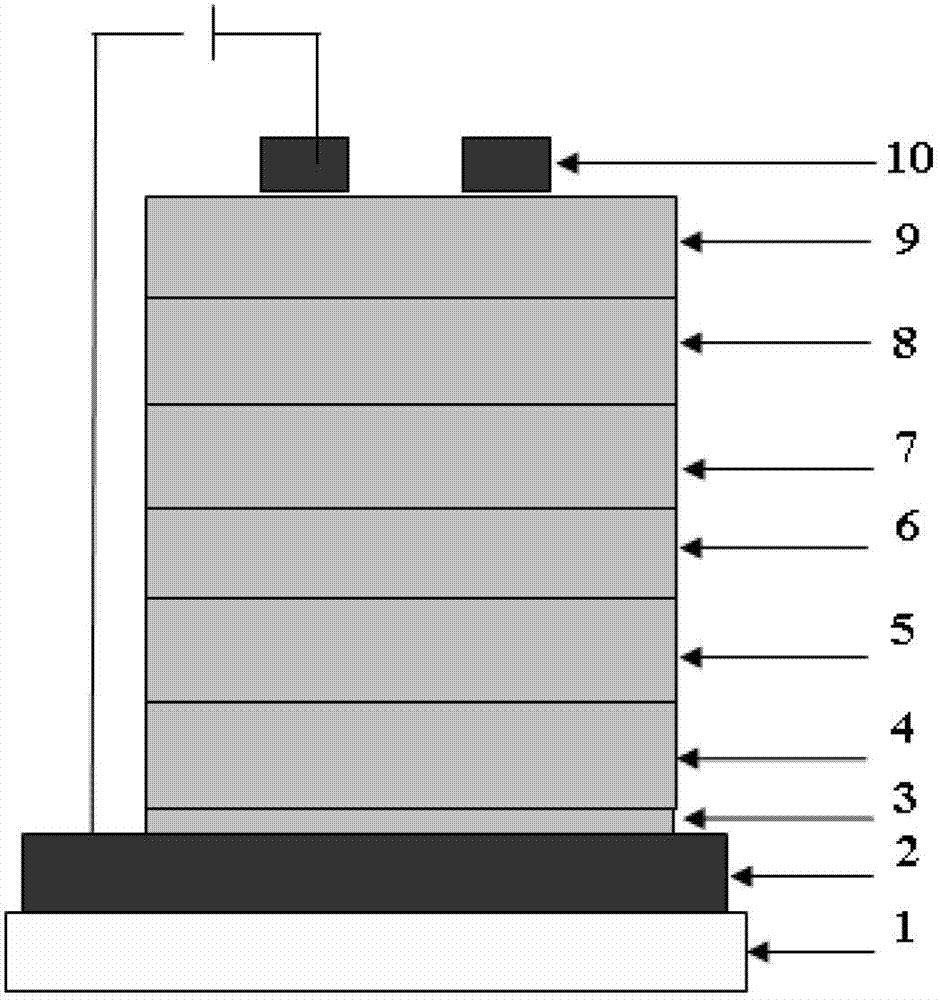

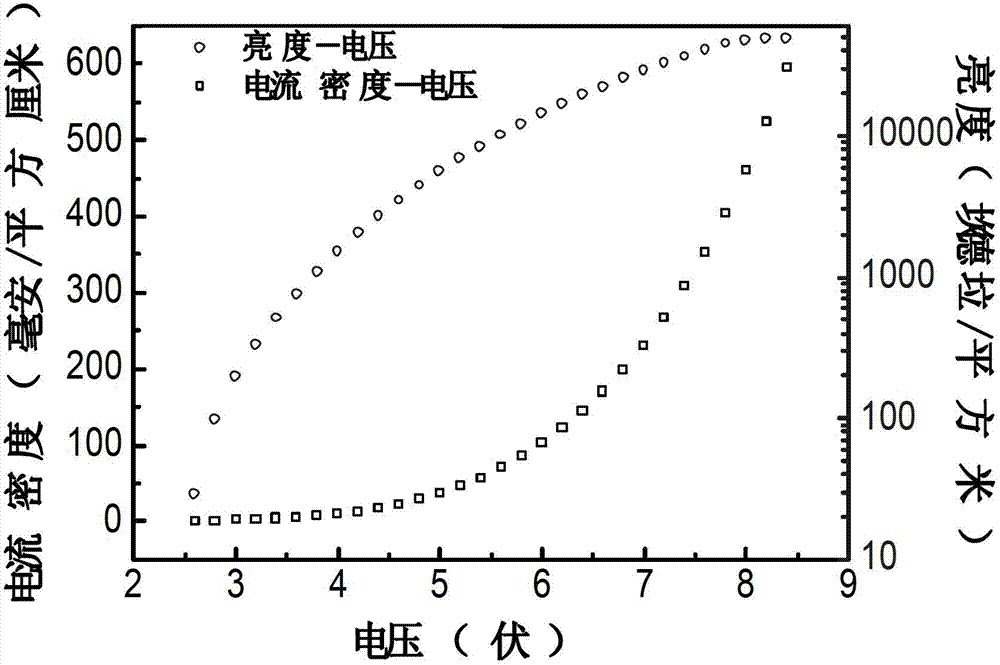

[0048] to combine figure 1 and figure 2 Illustrate present embodiment, first ITO on ITO glass 1 is photoetched into the electrode of 4 millimeters wide, 30 millimeters long, then described electrode is cleaned, nitrogen is blown dry and treated with oxygen plasma for 2 minutes, and in vacuum oven at 120 ℃ bake for 30min, and then transfer it to the vacuum coating system, until the vacuum degree reaches 1 to 5×10 -4 Pa, sequentially vapor-deposit M on the ITO electrode 2 O o 3 Hole injection layer 3, M O o 3 The hole transport layer 4 doped with NPB, the hole transport layer 5 of NPB, the light emitting layer 6 composed of BNE doped in the organic mixed host material composed of MADN and BANE, the electron transport / hole electron transport of Be(PP)2 Hole blocking layer 7, lithium carbonate doped Be (PP) Electron transport layer 8, lithium carbonate electron injection layer 9 and metal Al cathode 10, wherein two electrodes intersect with each other to form the light-emitt...

Embodiment 2

[0052] First, the ITO on the ITO glass is photolithographically formed into an electrode with a width of 4 mm and a length of 30 mm, then the electrode is cleaned, dried with nitrogen, treated with oxygen plasma for 2 minutes, and baked at 120 ° C for 30 minutes in a vacuum oven, and then Transfer it to a vacuum coating system until the vacuum reaches 1 to 5×10 -4 Pa, sequentially vapor-deposit V on the ITO electrode 2 o 5 hole injection layer, V 2 o 5 The hole transport layer doped with TCTA, the hole transport layer of TCTA, the light-emitting layer composed of pyrene doped in the organic mixed host material composed of MADN and BANE, the electron transport and hole blocking layer of Be(PP)2 , lithium carbonate-doped Be (PP) 2 electron transport layer, lithium carbonate electron injection layer and metal Al cathode, wherein two electrodes intersect with each other to form the light-emitting area of the device, the area of the light-emitting area is 16 square millimete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com