Triazine compound and organic light-emitting device comprising same

A technology of organic light-emitting devices and compounds, applied in the field of organic electroluminescence, which can solve problems such as device performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

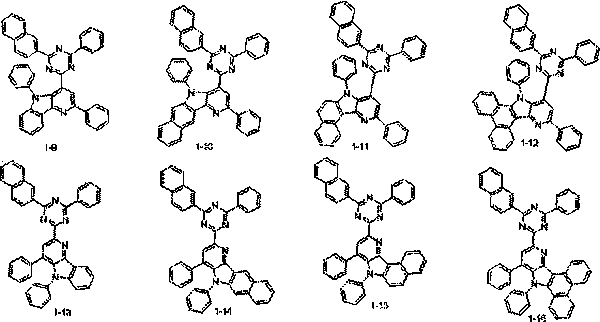

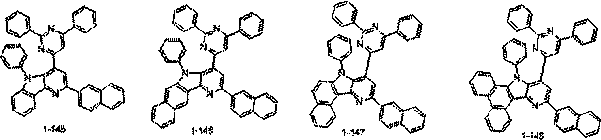

[0082] Synthesis of compound 1-1

[0083] (1) Synthesis of intermediate 1-1-1

[0084]

[0085] Add 2-(3-bromo-5-chlorophenyl)-4,6-diphenyl-1,3,5-triazine (0.8g, 1.18mmol), phenylboronic acid (0.2g, 1.66mmol), THF (30mL), potassium carbonate (2mol / L, 20mL), tetrakistriphenylphosphine palladium (100mg), and heated under reflux under nitrogen to react overnight. Stop the reaction, remove THF, extract three times with dichloromethane, combine the organic phases, wash with water until neutral, separate the organic phases, add anhydrous magnesium sulfate to dry, suction filter, spin dry; use silica gel column chromatography to obtain solid (0.41 g, yield 83%). LC-MS: M / Z 420.11 (M+H)+.

[0086] (2) Synthesis of Intermediate 1-1-2

[0087]

[0088] Add 2-(3-chloro-5-(pyridin-4-yl))-4,6-diphenyl-1,3,5-triazine (0.41g, 0.98mmol), 10- Nitrophenanthrene-9-boronic acid (0.25g, 1.47mmol), THF (40mL), potassium carbonate (2mol / L, 20mL), tetrakistriphenylphosphine palladium (100m...

Embodiment 2

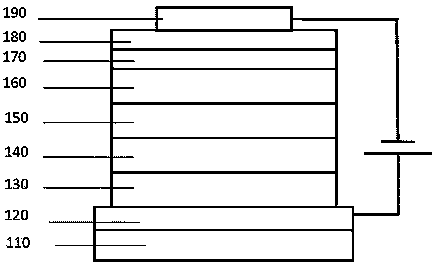

[0101] The transparent anode electrode ITO substrate was ultrasonically cleaned in isopropanol for 15 min and exposed to UV light for 30 min, followed by plasma treatment for 10 min. Then put the processed ITO substrate into the evaporation equipment. First evaporate a layer of 60nm NPB-DPA as the hole injection layer, the evaporation rate is 0.1nm / s, then evaporate 20nm NPB as the hole transport layer, the evaporation rate is 0.1nm / s, and then the light emitting layer The evaporation of mixed evaporation ADN / DPAVBi, the doping concentration is 2wt%, the evaporation rate of the matrix material is 0.1nm / s, the evaporation rate of the dopant material is 0.002nm / s, the evaporation thickness is 35nm, and then the evaporation Compound 1-1 was plated at 30nm as the electron transport layer at an evaporation rate of 0.05nm / s, and LiF and Al were vacuum-evaporated sequentially on the electron transport layer as the cathode with a thickness of 200nm.

Embodiment 3

[0103] The transparent anode electrode ITO substrate was ultrasonically cleaned in isopropanol for 15 min and exposed to UV light for 30 min, followed by plasma treatment for 10 min. Then put the processed ITO substrate into the evaporation equipment. First evaporate a layer of 60nm NPB-DPA as the hole injection layer, the evaporation rate is 0.1nm / s, then evaporate 20nm NPB as the hole transport layer, the evaporation rate is 0.1nm / s, and then the light emitting layer The evaporation of mixed evaporation ADN / DPAVBi, the doping concentration is 2wt%, the evaporation rate of the matrix material is 0.1nm / s, the evaporation rate of the dopant material is 0.002nm / s, the evaporation thickness is 35nm, and then the evaporation Plating 30nm of ET-1 as the electron transport layer, the evaporation rate is 0.05nm / s, and then 10nm of compound 1-1 as the hole blocking layer, and then vacuum-evaporating LiF and Al on the hole blocking layer as the cathode , with a thickness of 200nm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com