Antenna component and method for producing same

A manufacturing method and component technology, applied in the direction of inductance/transformer/magnet manufacturing, electrical components, waveguide devices, etc., can solve the problems of magnetic core material maintenance, winding magnetic core material and coil insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

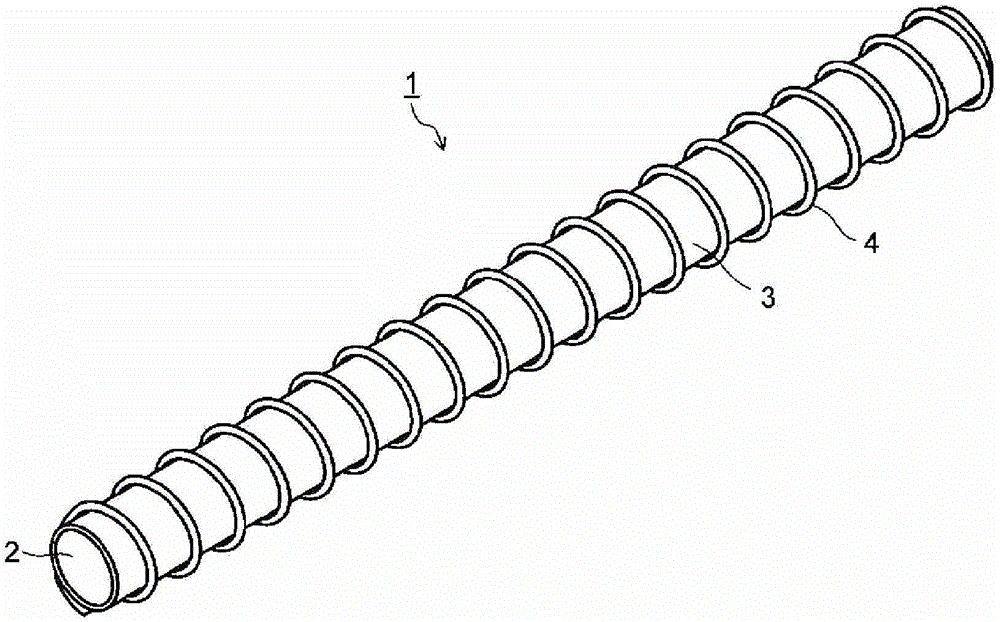

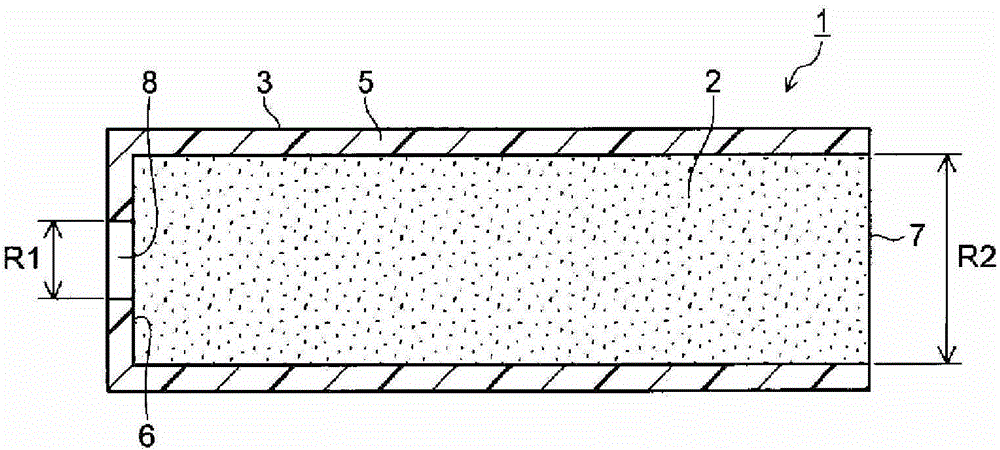

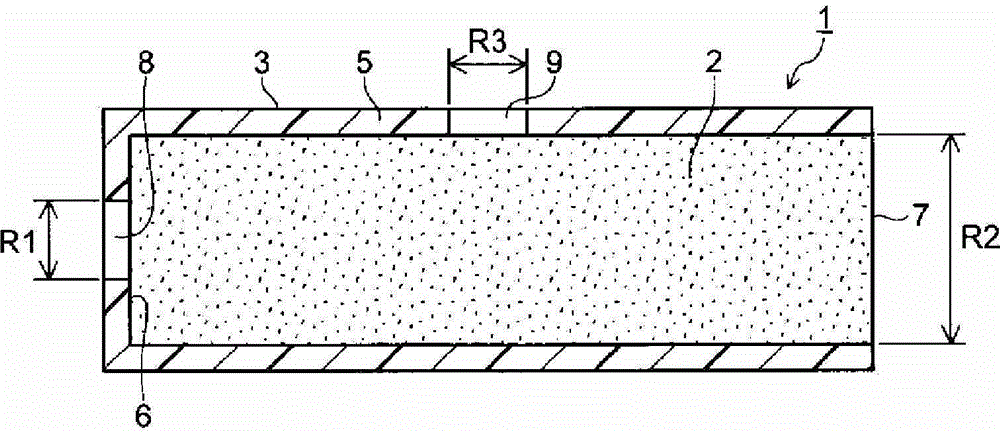

[0055] The manufacturing method of the antenna component according to Embodiment 1 includes the step of preparing a hollow component having a cylindrical portion having a dimension R2 inside, a partition wall portion provided at one end of the cylindrical portion, and a an opening at the other end of the cylindrical portion; a step of filling a mixture of soft magnetic powder and resin into the hollow component from the opening; a step of curing the resin in the mixture filled in the hollow component; and A process of winding a coil around the outer circumference of a hollow component. As described above, the partition wall portion is provided with a hole having a dimension R1 satisfying 0.05 mm≦R1≦0.5 mm and R1<R2.

[0056] First, soft magnetic powder and resin are mixed. The structure of the soft magnetic powder is as described above. In addition, the kind of resin etc. are as above-mentioned. Here, the viscosity of the resin is preferably in the range of 0.5 to 3 Pa·s at...

Embodiment approach 2

[0060] The manufacturing method of the antenna component of Embodiment 2 includes: the process of preparing the hollow component which has the cylindrical part of dimension R2 inside, the partition wall part provided in one end part of the cylindrical part, and the partition wall part provided in The opening of the other end of the cylindrical part; the process of forming and curing the mixture of the soft magnetic body powder and the first resin to obtain a magnetic body; the process of inserting the molded body into the hollow component from the opening; inserting the second A step of filling the gap between the hollow component and the molded body with a resin; a step of curing the second resin; and a step of winding a coil around the outer periphery of the hollow component. A hole is provided in the partition wall portion, and the hole has a dimension R1 satisfying 0.05 mm≦R1≦0.5 mm and R1<R2.

[0061] First, soft magnetic powder and resin are mixed. The structure of the ...

Embodiment 1)

[0067] Argon was introduced as a gas for plasma generation at 40 L / min into the chamber of the high-frequency induction thermal plasma apparatus to generate plasma. Fe powder with an average particle size of 10 μm and Al powder with an average particle size of 3 μm are sprayed into the plasma in the chamber at a rate of 3 L / min together with argon (carrier gas) at a mass ratio of Fe to Al of 20:1 . At the same time, acetylene gas, which is a raw material for carbon coating, is introduced into the chamber together with a carrier gas. Thus, nanoparticles in which FeAl alloy particles were coated with carbon were obtained.

[0068] The carbon-coated FeAl alloy nanoparticles were subjected to a reduction treatment at 500 mL / min of hydrogen flow at 600°C, cooled to room temperature, and then taken out into an argon atmosphere containing 0.1% by volume of oxygen and oxidized to produce a nucleus. Shell type soft magnetic powder. The obtained core-shell type soft magnetic powder h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com