Precise casing and shell-manufacturing method for sodium silicate

A technology of precision casting and water glass, which is applied in the fields of precision casting and water glass precision casting and shell making. It can solve the problems of equipment corrosion, less industrial application, and physical injury of operators, so as to reduce the production of ammonia gas and suppress ammonia gas. Air volatilization, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

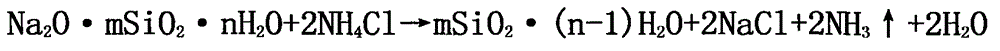

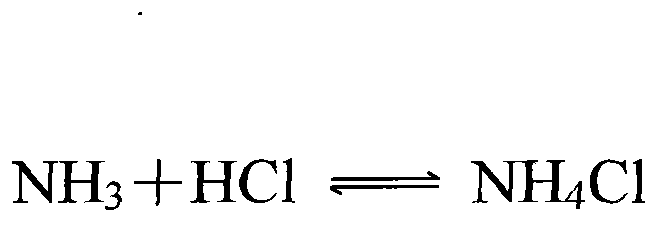

[0023] A water glass precision casting shell-making method, according to weight components, first take 3-5 parts of hydrochloric acid and put it in a hydrochloric acid container, then weigh 100 parts of water and put it into a hardening pool, and then put 18 parts of chlorine into the water in the hardening pool Ammonium chloride powder, after the ammonium chloride powder is fully dissolved, slowly inject the weighed salt, use the hardening state instrument to monitor the current intensity of the solution during the injection of hydrochloric acid, when the current reaches 150 mA, stop injecting hydrochloric acid into the hardening pool , and then put the shell-made casting into the hardening pool to harden, and complete the shell-making. When hardening, the water glass and ammonium chloride react to produce ammonia gas, part of the ammonia gas volatilizes, and most of it reacts with hydrochloric acid to form ammonium chloride.

Embodiment 2

[0025] A water glass precision casting shell manufacturing method, according to weight components, first take 3-5 parts of hydrochloric acid and put it in a hydrochloric acid container, then weigh 100 parts of water and put it into a hardening pool, and then put 20 parts of chlorine into the water in the hardening pool Ammonium chloride powder, after the ammonium chloride powder is fully dissolved, slowly inject the weighed salt, use the hardening state instrument to monitor the current intensity of the solution during the injection of hydrochloric acid, when the current reaches 150 mA, stop injecting hydrochloric acid into the hardening pool , and then put the shell-made casting into the hardening pool to harden, and complete the shell-making. When hardening, the water glass and ammonium chloride react to produce ammonia gas, part of the ammonia gas volatilizes, and most of it reacts with hydrochloric acid to form ammonium chloride.

[0026] The invention can not only make fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com