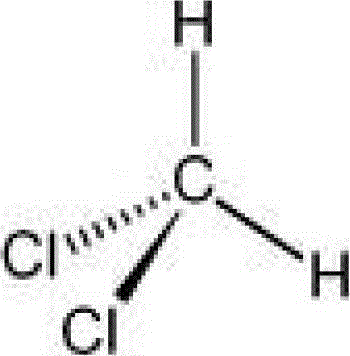

Method for purifying dichloromethane

A dichloromethane and purification method technology, applied in the field of dichloromethane purification, can solve the problems of long time and low purity, and achieve the effects of stable product quality, high purity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 1000ml of industrial dichloromethane into a 2000ml single-necked flask, dropwise add 20ml of sulfuric acid with a mass fraction of 95%, shake until the acid layer remains colorless, add 400mL of 9.5% sodium carbonate solution for washing for 25min, separate Dichloromethane, add 30g of calcium hydride, heat and reflux for 1h, then add 40g4A molecular sieve for adsorption and purification for 20min, and finally carry out rectification and collection at a flow rate of 20mL / min to obtain 903mL of purified dichloromethane with a yield of 90.3% and a purity of 99.54%. .

Embodiment 2

[0021] Add 1000ml of industrial dichloromethane into a 2000ml single-necked flask, dropwise add 25ml of sulfuric acid with a mass fraction of 95%, shake until the acid layer remains colorless, add 500mL of 10% sodium carbonate solution for washing for 30min, separate Dichloromethane, add 40g of calcium hydride, heat and reflux for 1.5h, then add 50g4A molecular sieve for adsorption and purification for 25min, and finally carry out rectification and collection at a flow rate of 15mL / min to obtain purified dichloromethane 917mL with a yield of 91.7% and a purity of 99.71 %.

Embodiment 3

[0023] Add 1000ml of industrial dichloromethane into a 2000ml single-necked flask, dropwise add 30ml of sulfuric acid with a mass fraction of 98%, shake until the acid layer remains colorless, add 600mL of 10.5% sodium carbonate solution for washing for 35min, separate Dichloromethane, add 50g of calcium hydride, heat and reflux for 2h, then add 60g4A molecular sieve for adsorption and purification for 30min, and finally carry out rectification and collection at a flow rate of 10mL / min to obtain 929mL of purified dichloromethane with a yield of 92.9% and a purity of 99.9%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com