Preparation method for carboxyl functionalized beta-NaYF4 substrate upconversion fluorescence nanomaterial

A technology of fluorescent nanomaterials and carboxyl functionalization, which is applied in the field of preparation of up-conversion fluorescent materials, can solve the problems of complicated and tedious operation steps, incapable of large-scale production, high labor intensity, etc., and achieves simple and safe operation, few kinds of raw materials, and water solubility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Accurately weigh 5 mmol of NH in a beaker 4 F solid, add 15 mL ethylene glycol solvent, sonicate for about 20 min to make NH 4 The F solid is completely dissolved to obtain solution A;

[0032] (2) Accurately weigh a total of 1.2 mmol of rare earth chloride (RECl 3 ) (RE=Y, Yb, Er; Y:Yb:Er = 80:18:2), 0.4 g sodium polyacrylate, the molecular weight of sodium polyacrylate is Mw = 5100, and 2.4 mmol sodium chloride, add 20 mL ethyl Diol, obtain solution B after ultrasonic dispersion;

[0033] (3) First transfer the B solution to a 50 mL autoclave, then add A to B under rapid stirring, continue to stir for 10 min to make it evenly mixed, tightly cover the autoclave, and react at 200 °C 12 hours;

[0034] (4) After the reaction, the reactants in the reactor were centrifuged, washed twice with water, and dried at 60°C to obtain carboxyl-functionalized β-NaYF 4 : Yb, Er up-conversion nano-fluorescent materials.

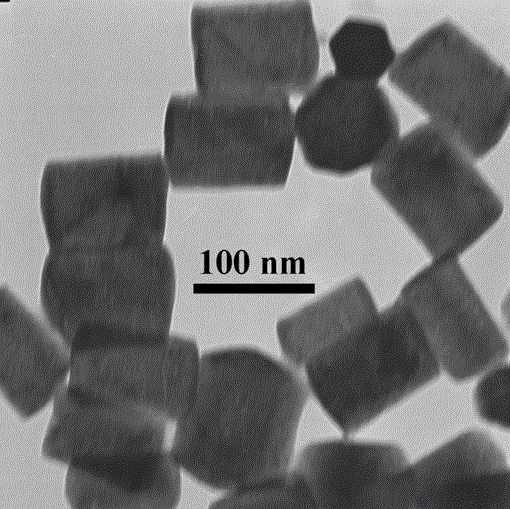

[0035] The prepared carboxyl functionalized β-NaYF 4...

Embodiment 2

[0038] (1) Weigh 5 mmol of NH in a beaker 4 F solid, add 15 mL ethylene glycol solvent, sonicate for about 20 min to make NH 4 F is completely dissolved to obtain solution A;

[0039](2) Accurately weigh a total of 1.2 mmol of rare earth chloride (RECl 3 ) (RE=Y,Yb,Tm; Y:Yb:Tm = 78:20:2), 0.4 g sodium polyacrylate, the molecular weight of sodium polyacrylate is Mw = 5100, and 2.4 mmol NaCl, add 20 mL ethylene glycol , solution B was obtained after ultrasonic dispersion;

[0040] (3) First transfer the B solution to a 50 mL autoclave, then add A to B under rapid stirring, continue to stir for 10 min to make it evenly mixed, tightly cover the autoclave, and react at 200 °C 12 hours;

[0041] (4) After the reaction, the product in the reactor was centrifuged, washed twice with water, and dried at 60°C to obtain carboxyl-functionalized β-NaYF 4 : Yb, Tm up-conversion nano-fluorescent material.

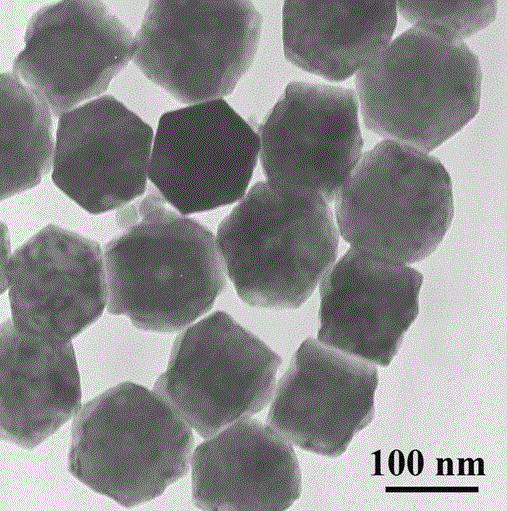

[0042] The prepared carboxyl functionalized β-NaYF 4 The fluorescence spectrum ...

Embodiment 3

[0044] (1) Weigh 5 mmol of NH in a beaker 4 F solid, add 15 mL ethylene glycol solvent, sonicate NH 4 F is completely dissolved to obtain solution A;

[0045] (2) Accurately weigh a total of 1.2 mmol of rare earth chloride (RECl 3 ) (RE=Y,Yb,Er; Y:Yb:Er = 80:18:2) and 0.4 g sodium polyacrylate, the molecular weight of sodium polyacrylate is Mw = 5100, add 20 mL ethylene glycol, and obtain after ultrasonic dispersion Solution B;

[0046] (3) First transfer the B solution to a 50 mL autoclave, then add A to B under rapid stirring, continue to stir for 10 min to make it evenly mixed, tightly cover the autoclave, and react at 200 °C 12 hours;

[0047] (4) After the reaction, the product in the reactor was centrifuged, washed twice with water, and dried at 60°C to obtain carboxyl-functionalized β-NaYF 4 : Yb, Er up-conversion nano-fluorescent materials.

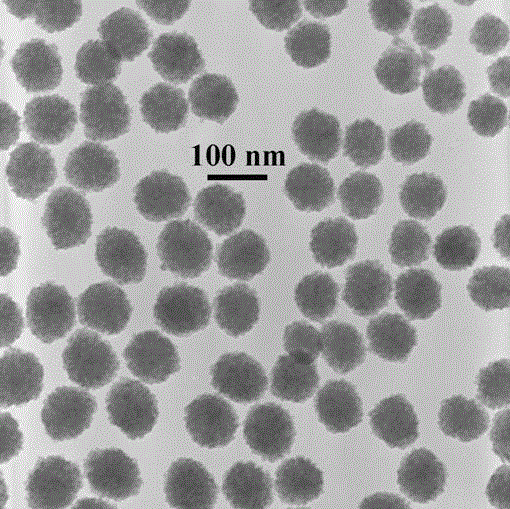

[0048] The prepared carboxyl functionalized β-NaYF 4 The transmission electron microscope image of the matrix up-conversi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com