Machine-made bamboo charcoal rod as well as manufacturing equipment and process thereof

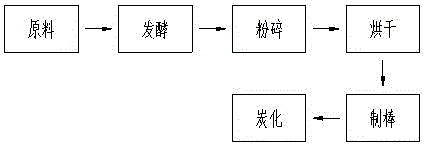

A technology of production process and production equipment, which is applied in the field of mechanism bamboo charcoal rods and its production equipment and process, can solve the problems of short burning time, low calorific value and low hardness, and achieve long burning time, high calorific value and high hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

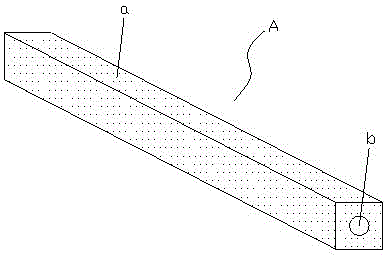

[0013] refer to figure 1 , a machine-made bamboo charcoal stick, including a stick body a, the middle part of the stick body a is provided with a through hole b running through the entire length, the through hole b can be but not limited to a round hole, the through hole b makes the stick When the body a burns, it can be burned inside and outside at the same time, which is conducive to the full combustion of the rod body a. The rod body a is processed from the leftovers of bamboo products after fermentation. .

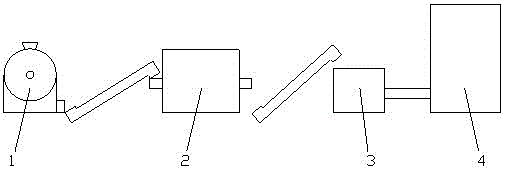

[0014] refer to figure 2 , a kind of production equipment of mechanism bamboo charcoal rod, comprises the pulverizer 1 that is used for pulverizing the leftovers of bamboo products after fermentation, and described pulverizer 1 is connected with the drier 2 that is used for drying the leftovers of bamboo products after pulverization, and des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com