Preparation method of aluminum-oxidized starch complex tanning agent

A technology for oxidizing starch and complex compounds, which is applied in the field of preparation of natural polymer tanning agents, can solve the problems of low shrinkage temperature of leather, easy tanning of leather, etc., and achieves difficult tanning, high leather yield and high fullness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

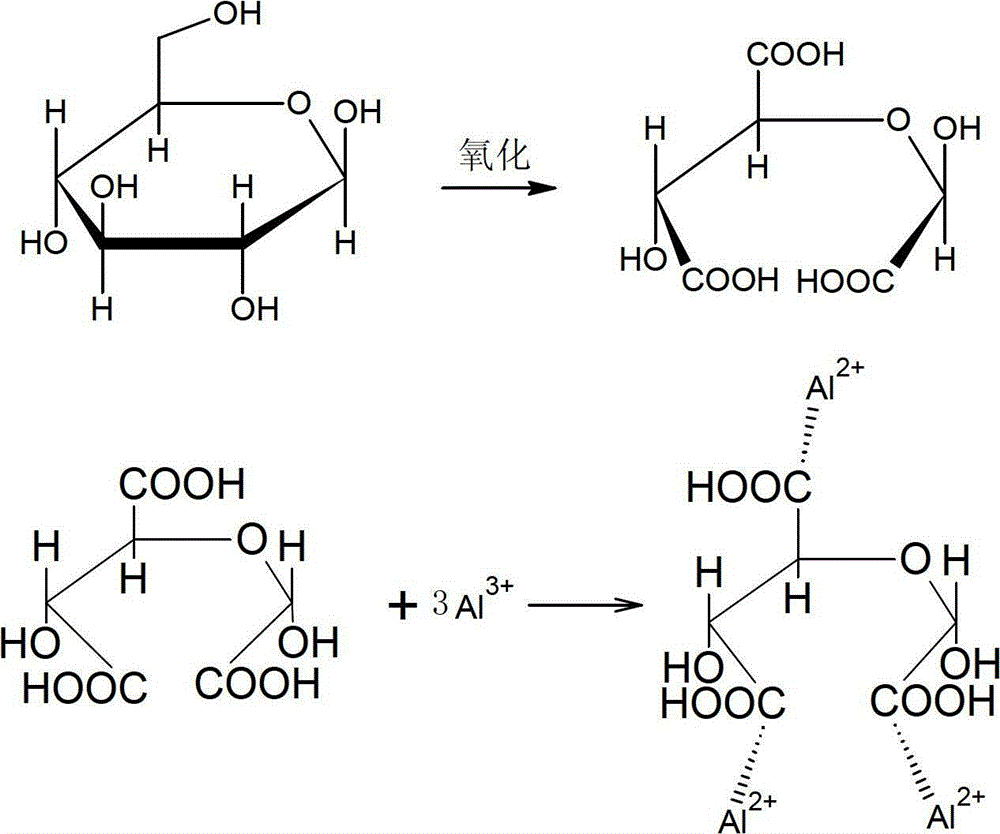

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Mix industrial cornstarch and water at a molar ratio of 1:10, then add catalyst ammonium metavanadate and concentrated nitric acid with a concentration of 75% to it in sequence, the molar ratio of catalyst to starch is 0.05:1, concentrated nitric acid The molar ratio to starch is 0.5:1, stirring and reacting at 10°C for 10h;

[0027] Step 2, extracting and washing the product of step 1 with ethanol to obtain oxidized starch with a high degree of carboxyl substitution;

[0028] Step 3, dry the oxidized starch and mix it with aluminum sulfate at a mass ratio of 0.5:1 to obtain a mixture. Now add water 100 times the total mass of the mixture to the mixture to fully dissolve it, and adjust the pH value to 3. At 20 Oscillate in a water bath constant temperature oscillator at ℃ for 30h;

[0029] Step 4: Place the solution after the oscillation reaction in a rotary evaporator to evaporate excess water, take it out, and place it in an oven at 60° C. to dry to obtain th...

Embodiment 2

[0031] Step 1: Mix industrial potato starch and water at a molar ratio of 1:5, and then add catalyst ammonium metavanadate and concentrated nitric acid with a concentration of 75% to it in turn. The molar ratio of catalyst to starch is 0.01:1, concentrated nitric acid The molar ratio to starch is 1:1, and the reaction is stirred at 30°C for 6h;

[0032] Step 2, extracting and washing the product of step 1 with acetone to obtain oxidized starch with a high degree of carboxyl substitution;

[0033] Step 3, dry the oxidized starch and mix it with aluminum sulfate at a mass ratio of 1:1 to obtain a mixture. Now add water 100 times the total mass of the mixture to the mixture to fully dissolve it, and adjust the pH value to 1. At 40 Oscillate in a water bath constant temperature oscillator at ℃ for 20h;

[0034] Step 4: Place the solution after the oscillation reaction in a rotary evaporator to evaporate excess water, take it out, and place it in an oven at 70° C. to dry to obtain...

Embodiment 3

[0036] Step 1: Mix industrial rice starch and water at a molar ratio of 1:8, then add catalyst ammonium metavanadate and concentrated nitric acid with a concentration of 75% to it in turn, the molar ratio of catalyst to starch is 0.08:1, concentrated nitric acid The molar ratio with starch is 2:1, stirring and reacting at 50°C for 4h;

[0037] Step 2, extracting and washing the product of step 1 with ethanol to obtain oxidized starch with a high degree of carboxyl substitution;

[0038] Step 3, dry the oxidized starch and mix it with aluminum sulfate at a mass ratio of 3:1 to obtain a mixture. Now add water 100 times the total mass of the mixture to the mixture to fully dissolve it, and adjust the pH value to 4. At 60 Oscillating in a water bath constant temperature oscillator at ℃ for 10h;

[0039] Step 4, place the solution after the oscillation reaction in a rotary evaporator to evaporate excess water, take it out and place it in an oven at 65° C. to dry to obtain the alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com