Watering and oil saving device for internal combustion engine

An internal combustion engine and water-gas technology, applied in the direction of charging system, mechanical equipment, engine components, etc., can solve problems such as uneven mixing of oil and water, engine vibration, unstable speed, etc., to achieve improved efficiency, stable performance, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

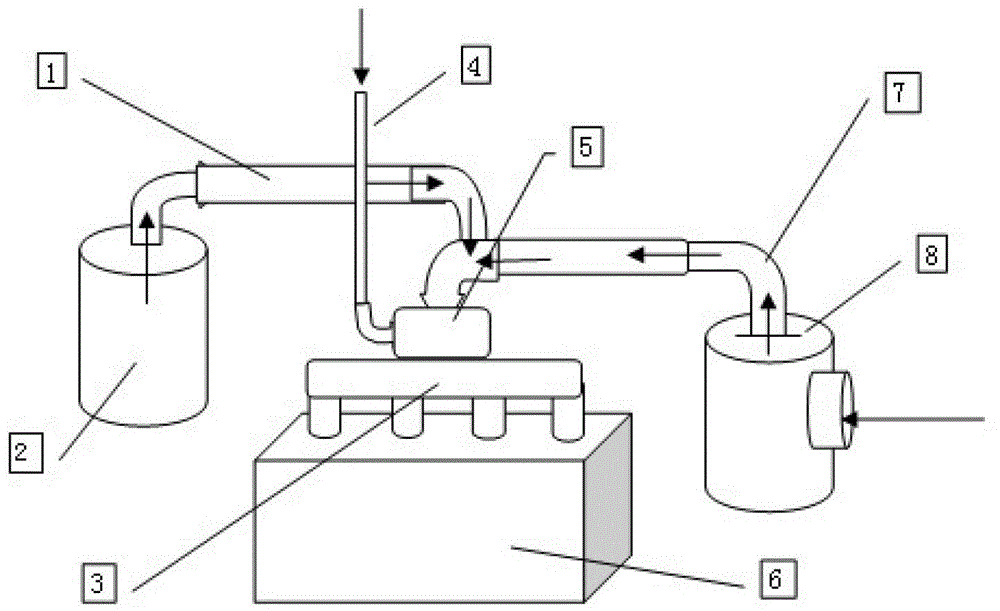

[0008] Attached below figure 1 The present invention is further described.

[0009] A water-mixing and fuel-saving device for an internal combustion engine, which includes an air guide pipe 1 before the air intake branch pipe 3 after the air filter 7 of the intake system of the internal combustion engine is installed, and the air guide pipe 1 communicates with a water vaporizer 2 to The steam is introduced into the internal combustion engine 8 .

[0010] This internal combustion engine water-mixing and fuel-saving device stores water separately outside the oil storage tank (tank), and only vaporizes the water from the carburetor when the internal combustion engine starts to work, and mixes the vaporized gaseous water and filtered clean air, Together into the internal combustion engine to do work. The blended water is stored independently and is not directly blended into the fuel as liquid water.

[0011] The device has an independent water vaporizer to vaporize water. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com