Strain SiGe square-in-square type channel NMOS (N-channel Metal Oxide Semiconductor) integrated device and preparation method thereof

An integrated device and channel direction technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc. Devices and circuits, restricting the development of the semiconductor industry and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

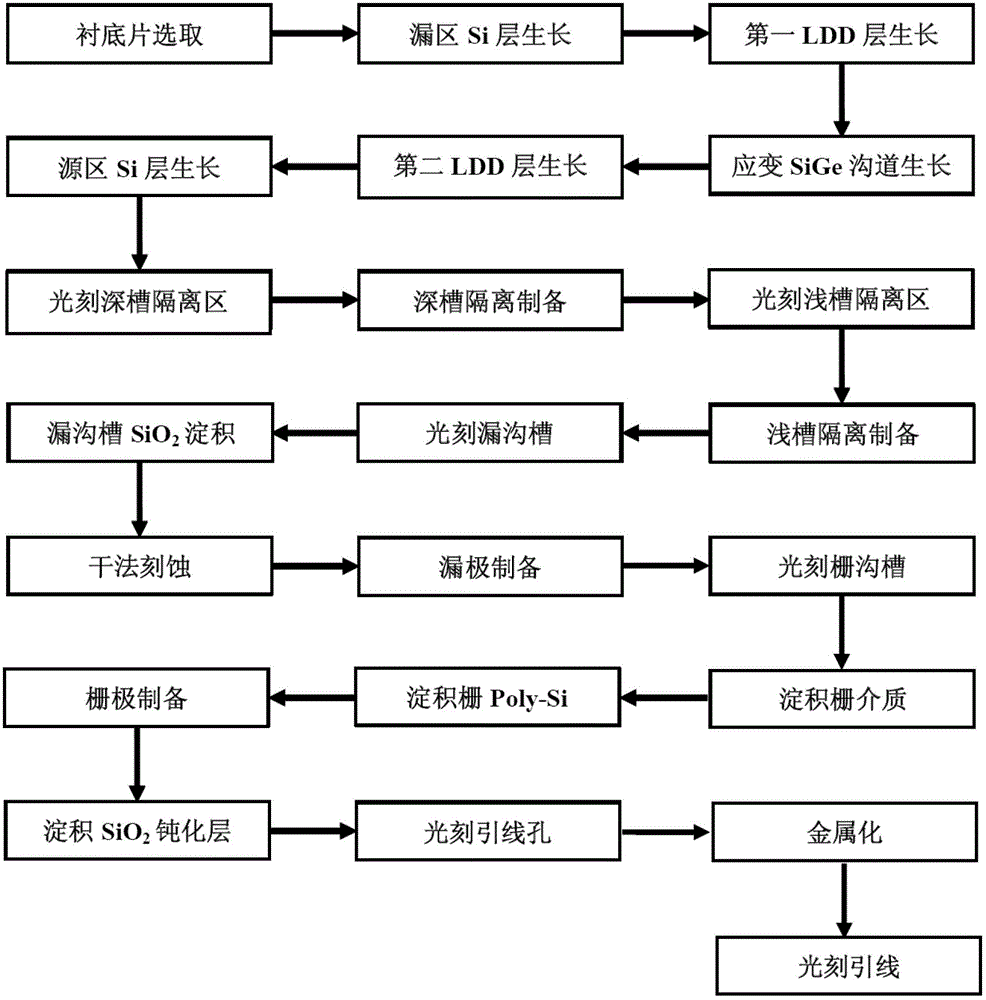

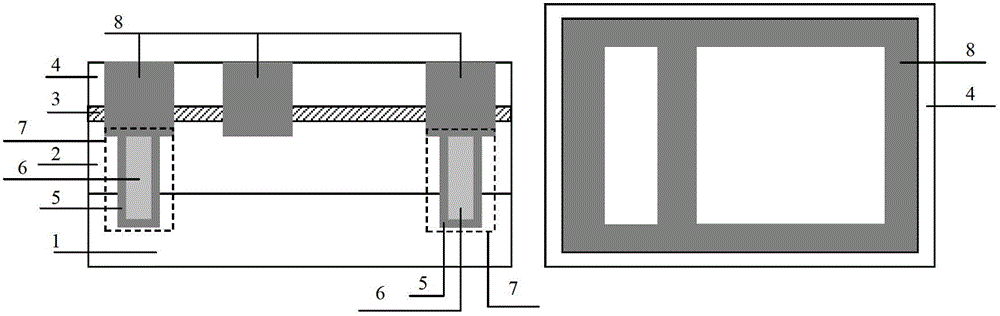

[0075] Embodiment 1: the preparation of the strained SiGe back channel NMOS integrated device and circuit with a conductive channel of 45nm, the specific steps are as follows:

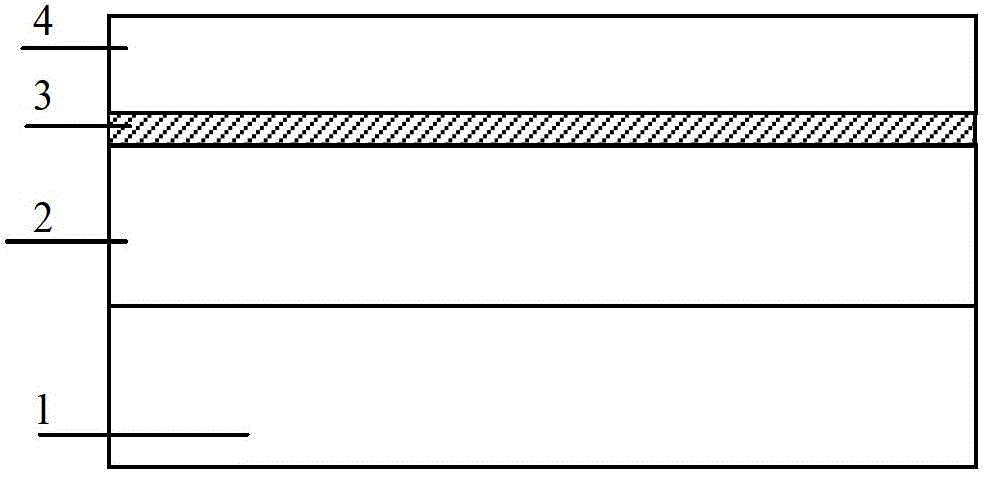

[0076] Step 1, epitaxial material preparation, as shown in Figure 2(a).

[0077] (1a) Select the doping concentration as 10 15 cm -3 Left and right P-type Si substrate sheets 1;

[0078] (1b) Using chemical vapor deposition (CVD), at 600°C, grow a layer of N-type Si epitaxial layer 2 with a thickness of 2.5 μm on the substrate as the drain region, with a doping concentration of 5×10 19 cm -3 ;

[0079] (1c) Using chemical vapor deposition (CVD), grow an N-type strained SiGe layer 3a with a thickness of 5nm on the substrate at 600°C, with a doping concentration of 5×10 17 cm -3 , the Ge composition is 10%, as the first lightly doped source and drain region (LDD) layer;

[0080] (1d) Using chemical vapor deposition (CVD), at 600°C, grow a P-type SiGe layer 3 with a thickness of 45 nm on the Si epi...

Embodiment 2

[0109] Embodiment 2: the preparation of the strained SiGe back channel NMOS integrated device and circuit with a conductive channel of 30nm, the specific steps are as follows:

[0110] Step 1, epitaxial material preparation, as shown in Figure 2(a).

[0111] (1a) Select the doping concentration to be 5×10 15 cm -3 Left and right P-type Si substrate sheets 1;

[0112] (1b) Using chemical vapor deposition (CVD), at 700°C, grow a layer of N-type Si epitaxial layer 2 with a thickness of 2.5 μm on the substrate as the drain region, with a doping concentration of 1×10 20 cm -3 ;

[0113] (1c) Using chemical vapor deposition (CVD), grow an N-type strained SiGe layer 3a with a thickness of 4nm on the substrate at 700°C, with a doping concentration of 1×10 18 cm -3 , the Ge composition is 10%, as the first lightly doped source and drain region (LDD) layer;

[0114] (1d) Using chemical vapor deposition (CVD), at 700°C, grow a P-type SiGe layer 3 with a thickness of 30 nm on the S...

Embodiment 3

[0143] Embodiment 3: the preparation of the strained SiGe back channel NMOS integrated device and circuit with a conductive channel of 22nm, the specific steps are as follows:

[0144] Step 1, epitaxial material preparation, as shown in Figure 2(a).

[0145] (1a) Select the doping concentration as 10 16 cm -3 Left and right P-type Si substrate sheets 1;

[0146] (1b) Using chemical vapor deposition (CVD), at 750°C, grow a layer of N-type Si epitaxial layer 2 with a thickness of 2 μm on the substrate as the drain region, with a doping concentration of 5×10 20 cm -3 ;

[0147] (1c) Using chemical vapor deposition (CVD), grow an N-type strained SiGe layer 3a with a thickness of 3nm on the substrate at 750°C, with a doping concentration of 5×10 18 cm -3 , the Ge composition is 10%, as the first lightly doped source and drain region (LDD) layer;

[0148] (1d) Using chemical vapor deposition (CVD), at 750°C, grow a P-type SiGe layer 3 with a thickness of 22nm on the Si epitax...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com