Rare-earth boride/boron carbide composite neutron absorption material and preparation method thereof

A technology of rare earth borides and absorbing materials, applied in the field of rare earth borides/boron carbide composite neutron absorbing materials and its preparation, can solve problems such as the influence of dysprosium titanate structure, reduce neutron absorption performance, etc., and achieve high neutron absorption , the effect of low swelling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

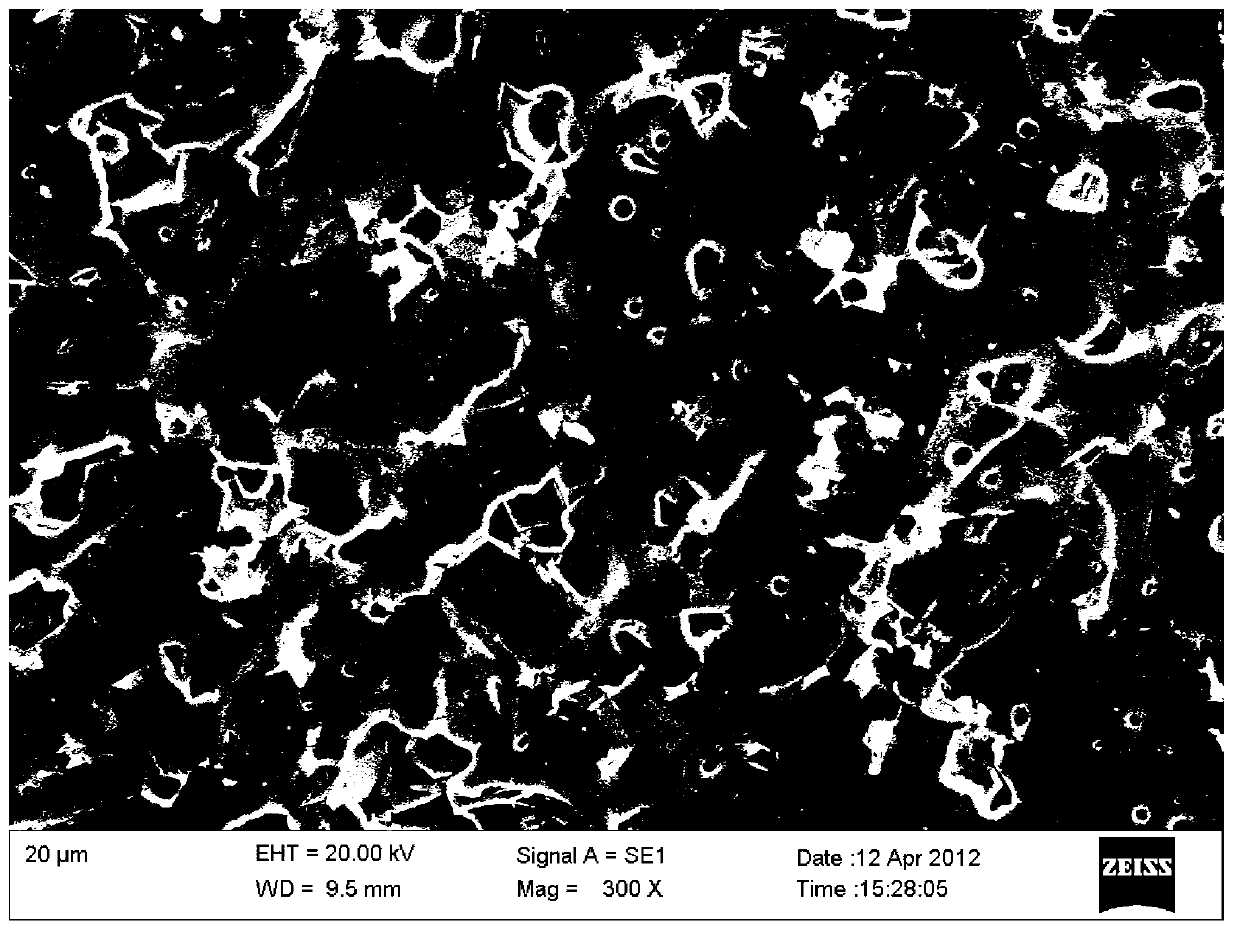

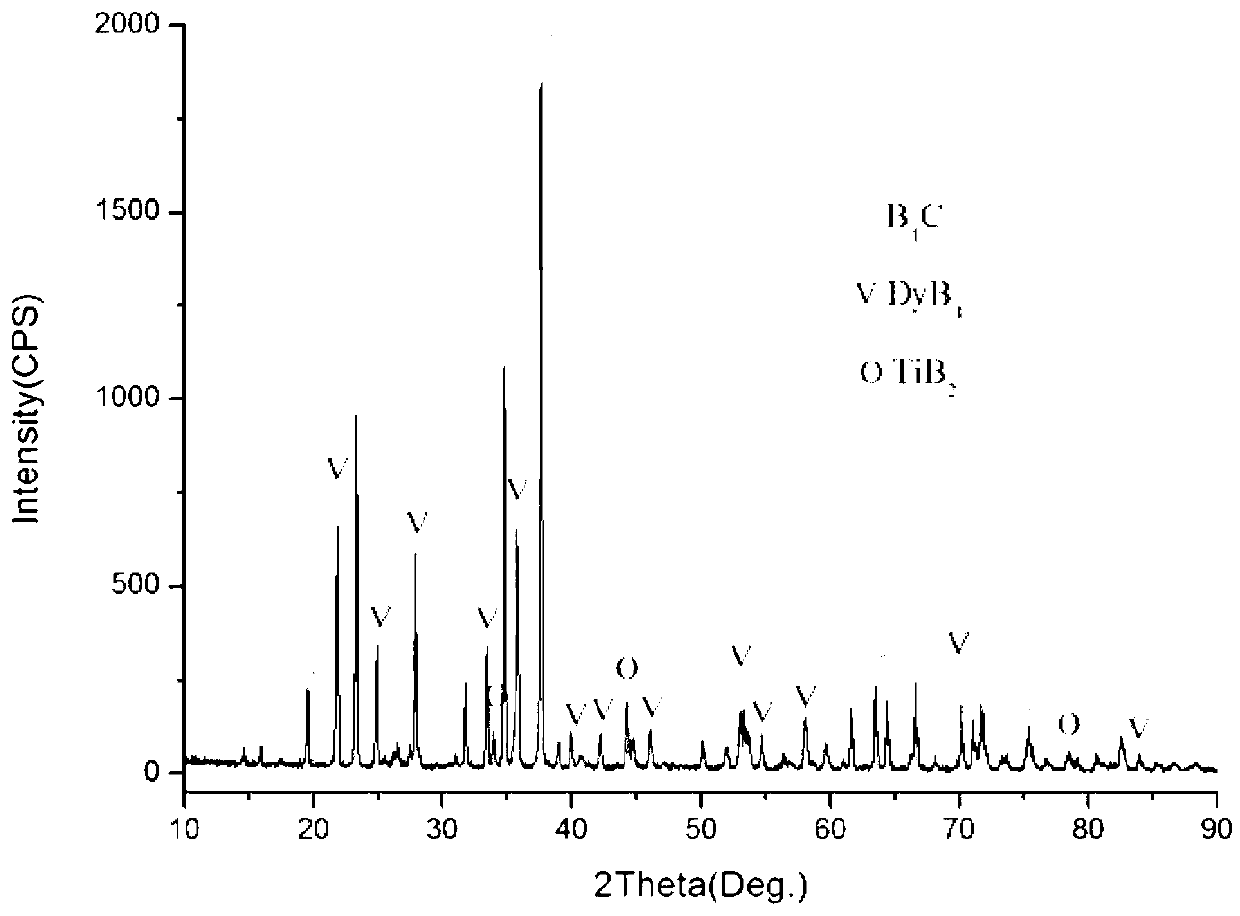

Image

Examples

Embodiment 1

[0045] Example 1: The raw material components of the rare earth boride / boron carbide composite neutron absorbing material are as follows: 90 parts of boron carbide powder, Eu 2 o 3 5 parts of powder, 5 parts of sintering aid carbon powder, both are parts by mass. The boron carbide powder was purchased from Mudanjiang Diamond Boron Carbide Co., Ltd., d 50 =1.5μm. The Eu 2 o 3 and carbon powder are analytically pure.

[0046] The preparation method steps are as follows:

[0047] 1. According to the ratio, boron carbide powder, Eu 2 o 3 1. The carbon powder is ball milled and mixed for 30 minutes with anhydrous methanol as the medium. The inner lining of the ball mill tank is polyurethane lining, and the grinding balls are boron carbide grinding balls or 99 ceramic balls. The obtained slurry is dried under vacuum conditions to obtain mixed powder.

[0048] 2. After the above-mentioned mixed powder is pre-pressed and formed, it is formed by a cold isostatic pressing machin...

Embodiment 2

[0051] Embodiment 2: raw material component and preparation step 1 are as described in embodiment 1, difference is:

[0052] Step 2, granulate the above-mentioned mixed powder, pass through a 200-mesh sieve, and put it into a corresponding graphite mold.

[0053] Step 3. Put the above powder into a sintering furnace for discharge plasma sintering, the maximum temperature is 1800°C, the maximum pressure is 40MPa, keep warm for 10min, and cool naturally to obtain a rare earth boride / boron carbide composite neutron absorbing material.

[0054] The properties of the obtained product are as follows: compressive strength 1.90GPa, bending strength 420MPa, elastic modulus 285GPa, relative density 96%. The neutron fluence rate of the components in the fast neutron reactor is 1.41×10 11 n / cm 2 · After 180 effective days of irradiation at s, the element maintains the integrity of the original shape and geometric dimensions after irradiation, and the swelling rate is 0.6%.

Embodiment 3

[0055] Example 3: The raw material components of the rare earth boride / boron carbide composite neutron absorbing material are as follows: 80 parts of boron carbide powder, Dy 2 o 3 15 parts of powder, sintering aid TiO 2 5 parts of powder, all are parts by mass. The boron carbide powder is 10 Enrichment of 95% of B abundance 10 B boron carbide powder, d 50 =1.5μm.

[0056] The preparation method steps are as follows:

[0057] 1. According to the ratio, boron carbide powder, Dy 2 o 3 、TiO 2 The powder is ball milled with anhydrous methanol as the medium, the lining of the ball mill tank is polyurethane lining, and the grinding balls are boron carbide grinding balls or 99 ceramic balls. The ball milling is mixed for 30 minutes, and the obtained slurry is dried under vacuum to prepare the mixed powder.

[0058] 2. Gel injection molding

[0059] Add the above mixed powder into the mixed solution of monomer acrylamide (AM), crosslinking agent N,N'-methylenebisacrylamide a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com