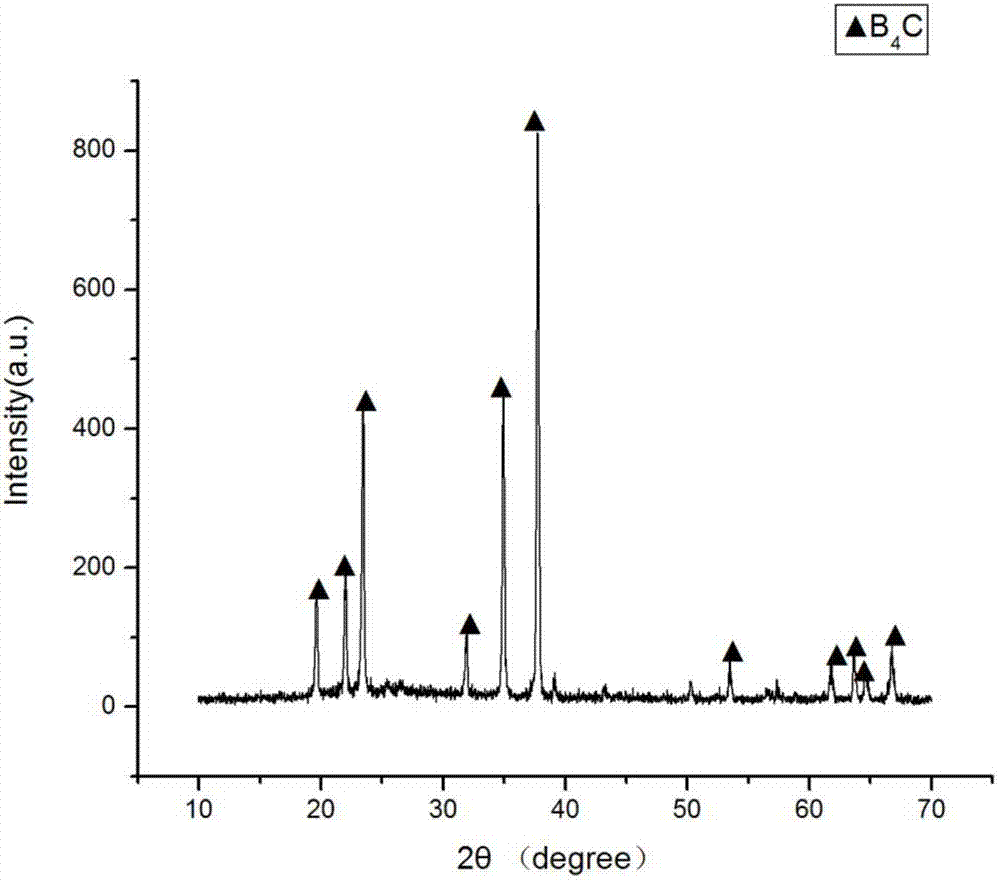

Preparation method for 10B-enriched boron carbide nanopowder

A boron carbide powder and nano technology, which is applied in the field of preparation of 10B-rich boron carbide nano powder, can solve the problems of increased production cost, low production capacity, large average particle size, etc., and achieves high neutron absorption and powder particle size. Small, low sintering temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Will 10 B richness of 65% rich 10 B boric acid powder (purity > 98%, d 50 <300μm, produced by Dalian Borntan Technology Co., Ltd.) 50g, mixed with 60ml of glycerol, ball milled and mixed, put into an alumina crucible, heated to 120°C in air, and kept for 2 hours to form a mixed liquid with uniform composition.

[0028] (2) The above liquid was put into a muffle furnace and heated in the air at a heating temperature of 450°C, a holding time of 0.5 hours, and a heating rate of 5°C / min.

[0029] (3) Grinding the product obtained after heating with an alumina mortar and passing through a 100-mesh sieve to form particles with a particle size of less than 1 mm.

[0030] (4) Press the above granules into cubes, the pressure is 20Mp, and the holding time is 3 minutes.

[0031] (5) Put the above-mentioned block into a graphite crucible, seal it, put it into a vacuum furnace, perform high-temperature treatment on it in a vacuum or argon atmosphere, raise the temperature to...

Embodiment 2

[0033] (1) Will 10 B richness of 68% rich 10 B boric acid powder (purity > 98%, d 50 <300μm, produced by Dalian Borntan Technology Co., Ltd.) 50g, mixed with 30ml glycerol, ball milled and mixed, put into an alumina crucible, heated to 150°C in air, and kept for 2 hours to form a mixed liquid with uniform composition.

[0034] (2) Put the above liquid into a muffle furnace and heat it in the air at a heating temperature of 550°C, a holding time of 1 hour, and a heating rate of 5°C / min.

[0035] (3) Grinding the product obtained after heating with an alumina mortar and passing through a 200-mesh sieve to form particles with a particle size of less than 1 mm.

[0036] (4) Press the above granules into cubes, the pressure is 30Mp, and the holding time is 5 minutes.

[0037] (5) Put the above-mentioned block into a graphite crucible, seal it, put it into a vacuum furnace, perform high-temperature treatment on it in a vacuum or argon atmosphere, raise the temperature to 1500°C a...

Embodiment 3

[0039] (1) Will 10 B abundance 90% rich 10 B boric acid powder (purity > 98%, d 50 <300μm, produced by Dalian Borntan Technology Co., Ltd.) 50g, mixed with 40ml of glycerol, ball milled and mixed, put into an alumina crucible, heated to 180°C in air, and kept for 2 hours to form a mixed liquid with uniform composition.

[0040] (2) The above liquid is put into a muffle furnace and heated in air at a heating temperature of 650°C, a holding time of 3 hours, and a heating rate of 5°C / min.

[0041] (3) Grinding the product obtained after heating with an alumina mortar and passing through a 100-mesh sieve to form particles with a particle size of less than 1 mm.

[0042] (4) Press the above granules into cubes, the pressure is 30Mp, and the holding time is 5 minutes.

[0043](5) Put the above-mentioned block into a graphite crucible, seal it, put it into a vacuum furnace, perform high-temperature treatment on it in a vacuum or argon atmosphere, raise the temperature to 1600°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com